tima's DIY RCM

- Thread starter tima

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello Neil,

Your knowledge is amazing, thank you so much for the comments!

1. Got the point on the concentration, will prepare a new mix with 0.02% S7

2. IPA concentration - how critical is it to keep 5%? What if drops to say 3%? I though this is rather arbitrary

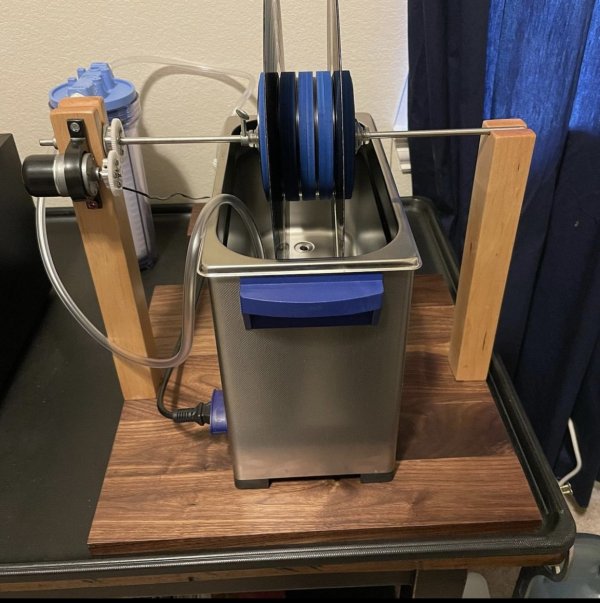

3. The pump is a cheap small unit:

View attachment 81511

The filter is a polyprop filter FilterLogic SP10M005. I think this is something local, cannot find any data on the 0.5um rating. I'd assume its a lesser rather than the better. To give you some idea, I needed about 10h filtering to bring TDS from initial 11ppm to 7ppm (cleaning in the mean time 12 vinyls).

4. Got the point on the power, will increase to 100%, 10mins. Back at the time when I was starting US, there was a fear too much power may affect high frequencies.

Once again, thank you so much Neil, this looks like almost 50% time reduction per batch of 3 LPs.

Best,

Jarek

Jarek:

WRT to the IPA, there is no magic number that makes it best. In the USA, many people use only the Tergitol with no IPA. For those that want to use IPA, I recommend only 2.5% to err on the very safe side of any fire hazard in case someone adds a little extra. No UCM people are buying to clean records is explosion proof rated. But, 5% is pretty safe with a flashpoint of 120F (49C). Some people are not happy unless they are using IPA, so I have accommodated that while not recommending any % that could be unsafe. However, at 2.5-5% the IPA is not doing much, but it reduces the fluid boiling point (vapor pressure) which at 5% may reduce cavitation intensity. Low vapor pressure fluids do not make good fluids for cavitation. The optimum is water because it has a high vapor pressure - its a 'stiff' fluid so the cavitation bubble internal pressure is higher and then implodes with maximum force. Given that your UCM is low power, I would reduce IPA to 2.5%, and maybe try without since your are doing a good pre-clean.

The Tergitol is what decreases the surface tension and with the right concentration provides detergency, and the Tergitol which has almost the same density as water, and is used at such low concentrations it does not affect the fluid cavitation intensity potential. But, the 2.5% IPA 'may' assist with something called soil-roll-up (see the book VIII.8.6) and this becomes important if you are not doing a pre-clean.

Note that most people that use Tergitol use 15-S-9 which has a higher cloud point and slightly higher detergency and is readily available for cheap purchase ins the USA via Tergitol 15-S-3 and 15-S-9 Surfactant | TALAS (talasonline.com). Tergitol 15-S-7 is generally difficult to purchase and the lab-versions are very expensive. Not sure of your location, but for those in UK/EU, I generally recommend Dehypon – Conservation Resources (UK) Ltd (conservation-resources.co.uk) Dehypon LS54 which is a similar nonionic surfactant and the cost is very low. However, no there is no reason to shift from 15-S-7 to LS54.

Here are the best details I found for your pump/filter (there are no detailed cut-sheets); Machifit QR30E Ultra-quiet Mini Brushless Pump DC 12V 4.2W 240L/H Flow Rate Submersible Water Pumps | Alexnld.com & SP10M005 FilterLogic 10” Slimline Spun Poly Sediment Water Filter 0.5 Micron | eBay.

Based on the filter price, the 0.5um sediment filter will be a nominal filter that can generally pass particles as large as 5 microns, but has low pressure drop which is good, because the pump only has a maximum head (lift) of 3m (9.8ft) which is very little, and you would not want to use this pump with an absolute rated filter. The pump is a centrifugal pump and with the pump flow of 240 lph (~1 gpm) at max you are probably getting in-use about 0.5-0.75 gpm (2-3 lpm). At this flow, with your 6L tank you need to run the pump about 10 minutes to filter 97% of the tank. If you want the details - read Section XIV.15.1 of the book. However, keep this in-mind. TDS = Total "Dissolved" Solids. The filter only removes "suspended" solids. You cannot use TDS as a measure of Total Suspended Solids (TSS); they are completely different.

Yeah, probably more than you wanted to know, but to dial-in a cleaning process with what you have, the Devil is in the Details.

Best Regards,

Neil

Amen to that!I am in the camp of once the LP has been rinsed in my tank and dried the only thing that touches the surface is the inner sleeve and the stylus. I try to never brush the record surface if I can avoid it.

5. We have a point ionizing blower mounted above the TT's, model ION 6421a. We use it while dry brushing and handling LP's just before/after the playback. I also used to dry LP's after cleaning under it but now just blow a bit of the ionized air into the sleeve.

Recently we start installing stat traps to reduce ion blower use and the ozone production https://www.tnt-audio.com/clinica/stat_trap_e.html (we use 12um steel rather than carbon brush as it is many times better conductive albeit more expensive).

Jarek,

If you read the book Chapter VI you will see where I am using an ESD mat for the platter mat (I use a VPI screw-down clamp) along with the platter bearing/spindle being grounded.

FYI - my discussion of corona is VI.9.2.a is wrong. Not sure why I used the word electron when I should have used the word 'ion'; lets skip the positive-electrons - ouch. Either way, the correct discussion should be: The corona effect if from a VAC source produce alternating positive and negative ions; and if from a VDC source produce either negative or positive ions. And for others reading, positive ions are atomic elements or molecules that have lost electrons, and negative ions are atomic elements or molecules that have gained electrons. But some static eliminators are based on the corona effect -Technical Guide - STATIC REMOVERS (IONIZERS) (panasonic.biz . The plasma created by the inexpensive 'arc lighter' such as RONXS™ Home | RONXS is from VDC (and is different from a short term high current arc discharge) and depending on the electrode charge the resulting corona will produce either positive ions or negative ions. The arc lighter acts as a static eliminator for the record since it produces a corona that is producing a field/zone of positive ions that surround the plasma and those positive ions (made up from air - mostly oxygen + nitrogen) are what neutralize the record static similar to a static remover (ionizer). However, the field/zone of ionized gas (air) is finite and that is why the arc-lighter needs to be located quite close to the record to work. Ionizers such as that described by Panasonic are used in industry and use a fan or compressed air to extend the reach of the ions to the surface of interest.".

Take care,

Neil

Hi Tim,I'm not aware of inner sleeve shedng. Do they shed without records in them?

I have had that happen with some sleeves (I use the Mobile Fidelity or equivalent). I only see this for a period of time - maybe the 1st 2-3 plays. I will notice detritus on the record (under UV light) before play - looks like lint and just brush it away (Anti-Static Tiger Cloth | kinetronics). Since the sleeves fluoresce its hard to detect - however, I have wiped the the sleeve inside with the Tiger Cloth and saw little evidence of particles (the Tiger Cloth does not fluoresce). So this somewhat confirms shedding and its probably the equivalent of whiskers that just a consequence of the manufacture (and likely lot to lot different) are abraded (sanded) away with the insertion/removal of the record. The Tiger Cloth is too soft to remove the 'whiskers" for want of a better name.

Take care,

Neil

Hi Bill,Neil turned me on to that Tiger Cloth and it does work- it may leave a smudge but I don't want to pronounce that as the last word until I use it more.

I have not experienced that - but I only use it very lightly on the record for dusting. Recommend you inspect the cloth with your UV light and confirm no fluorescence, and if new, you may want to hang for 24-hrs at room temp to allow any type of 'dry-cleaner' that they may have used to evaporate. Then shake to dislodge any particles.

Take care,

Neil

Jarek:

WRT to the IPA, there is no magic number that makes it best. In the USA, many people use only the Tergitol with no IPA. For those that want to use IPA, I recommend only 2.5% to err on the very safe side of any fire hazard in case someone adds a little extra. No UCM people are buying to clean records is explosion proof rated. But, 5% is pretty safe with a flashpoint of 120F (49C). Some people are not happy unless they are using IPA, so I have accommodated that while not recommending any % that could be unsafe. However, at 2.5-5% the IPA is not doing much, but it reduces the fluid boiling point (vapor pressure) which at 5% may reduce cavitation intensity. Low vapor pressure fluids do not make good fluids for cavitation. The optimum is water because it has a high vapor pressure - its a 'stiff' fluid so the cavitation bubble internal pressure is higher and then implodes with maximum force. Given that your UCM is low power, I would reduce IPA to 2.5%, and maybe try without since your are doing a good pre-clean.

The Tergitol is what decreases the surface tension and with the right concentration provides detergency, and the Tergitol which has almost the same density as water, and is used at such low concentrations it does not affect the fluid cavitation intensity potential. But, the 2.5% IPA 'may' assist with something called soil-roll-up (see the book VIII.8.6) and this becomes important if you are not doing a pre-clean.

Note that most people that use Tergitol use 15-S-9 which has a higher cloud point and slightly higher detergency and is readily available for cheap purchase ins the USA via Tergitol 15-S-3 and 15-S-9 Surfactant | TALAS (talasonline.com). Tergitol 15-S-7 is generally difficult to purchase and the lab-versions are very expensive. Not sure of your location, but for those in UK/EU, I generally recommend Dehypon – Conservation Resources (UK) Ltd (conservation-resources.co.uk) Dehypon LS54 which is a similar nonionic surfactant and the cost is very low. However, no there is no reason to shift from 15-S-7 to LS54.

Hi Neil,Here are the best details I found for your pump/filter (there are no detailed cut-sheets); Machifit QR30E Ultra-quiet Mini Brushless Pump DC 12V 4.2W 240L/H Flow Rate Submersible Water Pumps | Alexnld.com & SP10M005 FilterLogic 10” Slimline Spun Poly Sediment Water Filter 0.5 Micron | eBay.

Based on the filter price, the 0.5um sediment filter will be a nominal filter that can generally pass particles as large as 5 microns, but has low pressure drop which is good, because the pump only has a maximum head (lift) of 3m (9.8ft) which is very little, and you would not want to use this pump with an absolute rated filter. The pump is a centrifugal pump and with the pump flow of 240 lph (~1 gpm) at max you are probably getting in-use about 0.5-0.75 gpm (2-3 lpm). At this flow, with your 6L tank you need to run the pump about 10 minutes to filter 97% of the tank. If you want the details - read Section XIV.15.1 of the book. However, keep this in-mind. TDS = Total "Dissolved" Solids. The filter only removes "suspended" solids. You cannot use TDS as a measure of Total Suspended Solids (TSS); they are completely different.

Yeah, probably more than you wanted to know, but to dial-in a cleaning process with what you have, the Devil is in the Details.

Best Regards,

Neil

Thank you so much for another portion of knowledge. Definitely not too much

1. Will reduce the IPA to 2.5% in the USC

2. What parameters (Hmax I guess) must the pump have to reliably push through 0.5um or 1um absolute?

3. Does it make sense to go to 0.5um or 1um is enough? Could you pls give a sample of a absolute filter, pref. from a global brand so that I can find it locally?

I'm considering getting a 6L Elmasonic P60H unit for the main cleaning and leaving the existing unit for rinsing. The rinsing really kills me.

Cheers,

Jarek

Amen to that!

Interesting, what is the rationale behind such an approach?

@tima - Hi Tim. I don't know when and why the brush seemed more effective when it was brand new. I don't use it that much upstairs but had it in the vintage system room for a while. I recently brought it back upstairs to the main system to try again.

The inner shedding may be only part of the problem, along with whatever dust motes or other stuff are in the room; but in both systems, both rooms are dedicated, no pets allowed, good HVAC and regular filter changes and I'm OCD enough to clean around the playing area pretty constantly.

The air ionizers for bench top IC work are probably more cost effective than the ones made for audio. Some are cheapies, others can be found used on E-Bay. I may try one and see how it works.

The alternative- a cleanroom is the only logical next step.

regards,

Bill

The inner shedding may be only part of the problem, along with whatever dust motes or other stuff are in the room; but in both systems, both rooms are dedicated, no pets allowed, good HVAC and regular filter changes and I'm OCD enough to clean around the playing area pretty constantly.

The air ionizers for bench top IC work are probably more cost effective than the ones made for audio. Some are cheapies, others can be found used on E-Bay. I may try one and see how it works.

The alternative- a cleanroom is the only logical next step.

regards,

Bill

Jarek:Hi Neil,

Thank you so much for another portion of knowledge. Definitely not too much

1. Will reduce the IPA to 2.5% in the USC

2. What parameters (Hmax I guess) must the pump have to reliably push through 0.5um or 1um absolute?

3. Does it make sense to go to 0.5um or 1um is enough? Could you pls give a sample of a absolute filter, pref. from a global brand so that I can find it locally?

I'm considering getting a 6L Elmasonic P60H unit for the main cleaning and leaving the existing unit for rinsing. The rinsing really kills me.

Cheers,

Jarek

Here is a pump and filter that are sold from the UK and should ship to Poland.

1. Pump - SHURflo™ Model SLV10-AA40 or AA48 - Agratech NW Ltd > Shurflo Pumps > Shurflo SLV10-AA40 12v Pump 40 PSI 3.8 Ltrs/Min (1.0 US GPM). This is the pump I discuss in "XIV.16.2.b SHURflo™ Model SLV10-AA48 is 12VDC rated at 0.73 gpm at 10 psi head and 0.49 gpm at 30 psi head(max) and comes with a 40-psi (2.7 bar) overpressure shutoff (demand switch); manual on/off switch and a 2-pin connector. The Model SLV10-AA40 is the same pump without a 2-pin connector. This pump is self-priming to 2.5-ft and is supplied with 3/8-inch barb connectors. This pump will require a separate desktop style 120VAC/12VDC power source rated at not less than 40 watts such as the Mean Well™ Model GST40A12 or GST60A12. This pump’s low flow makes its suitable for smaller volume tanks.". Here is the cut-sheet. If you buy - be gentle with the barb fittings so you do not collapse.

2. Spectrum PPP-0.2-93/4AAS Spectrum PPP Spectrum Premier Pleat Sediment Filters 93/4in Open Ended AAS From £44.40 - Spectrum Water Filters by Wrekin Water Filtration. This a 0.2 micron absolute (no real need for 0.1um). The site has a cut-sheet and the filter maximum pressure differential is 4-bar (59 psi), so the pump will auto shut-off before collapsing the filter.

3. Note that the pump is a displacement pump and flow rate varies very little with pump discharge head. However, as I state in the book, diaphragm pumps can develop pressures high enough to require over pressure protection and these are provided as a ‘demand switch” which the Shurflo has. If you want you can buy a pressure gauge in install in the hose to the filter inlet. The gauge pressure will indicate the filter pressure drop since the filter outlet discharges to essentially 0 psig. The pump has enough head to get maximum benefit of the filter, and the filter should last a very long time, months if not many months if not a year.

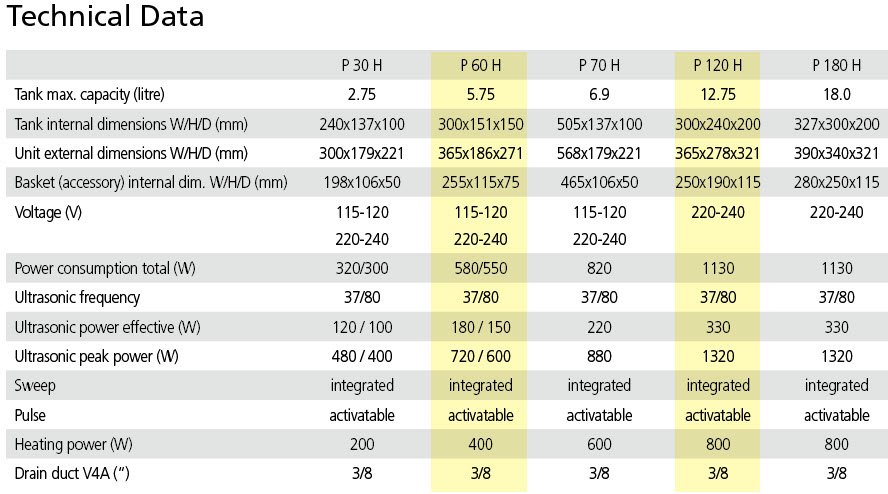

4. WRT to the Elmasonic P60H, Tima and Dminches both use the larger P120H and I am quite sure they can wax quite eloquently on its superior performance.

Take care,

Neil

Thanks a lot Neil!

So even 0.2um is better! Ok

As far as I understand the difference between P60H and 120H is just the volume 6L vs 12L or is there sth more?

Best,

jarek

So even 0.2um is better! Ok

As far as I understand the difference between P60H and 120H is just the volume 6L vs 12L or is there sth more?

Best,

jarek

Bill:The alternative- a cleanroom is the only logical next step.

Word to the wise, clean rooms with their hard no-shedding surfaces and somewhat sterile environments will make for an awful sounding room. The small amount of detritus that deposits on the record from the sleeve or drops from the air is actually of little consequence. Just brush/swipe away. But, do not think that what you see is only the tip of the iceberg - its should not be.

Larger particles will deposit/fall from the air exponentially faster than smaller particles. Once the record is spinning it develops its own air current which should 'shield' the record from all but the largest particles depositing. Paraphrasing an article - particle settling rate, the rate of surface accumulation is proportional to the airborne concentration which is differentiated by the particle size, the exposure time, and the orientation of the surface relative to the air flow. Surfaces parallel to the average direction of flow and at right angles to gravity sustain the lowest particle accumulation.". If you check CACR25_FINAL_LR.pdf (gla.ac.uk) Figure 4 you will see where the Deposition Velocity for the small stuff <5 um is very slow, but the big stuff>25um is much faster. Placing your table under air register is not prudent.

Don't over think this. There is some science to keep us from going crazy.

However, this does lead to the question posed by Jarek,

Interesting, what is the rationale behind such an approach?

To quote from my book - "VI.2 In the paper Record Contamination: Causes and Cure by Percy Wilson, 1965, (52) it echoes what Harold D. Weiler wrote and discusses how dry cleaning can give back more than it removes. The dry-cleaning material will ultimately become saturated with particle/soil and then instead of removing, redeposits to the record. The paper also states that “…repeatedly-used damp pad or like device can become a positive menace.”.

Think of the ubiquitous carbon brush - quoting from my book: VI.8.a CARBON FIBER: A very fine [Ø 0.000283] (~7.6 microns) fiber of 95% pure carbon. Fiber has a tensile strength of 575 ksi, a tensile modulus of 35 msi, and an electrical resistivity of 0.00055 Ohms in. Popular in light touch to non-contact grounding brushes due to its high conductivity. Not recommended for uses with high flexural requirements since carbon fiber has low flex fatigue resistance and can break off rather easily.” Carbon fiber is stronger than steel along its shaft, but cross-wise, its very fragile is brittle.

Quoting from my book - VI.8.d A simple observation of a carbon fiber or Thunderon® record brush with bright white light or UV blacklight at 30 to 45-degree angle can observe that the brushes often only move the dust. This is consistent with the NASA/TM—2011-217231, report on Evaluation of Brushing as a Lunar Dust Mitigation Strategy for Thermal Control Surfaces (49) that evaluated the effectiveness and performance of various brush materials and designs to remove dust from thermal control paint or aluminized thermal control surface. The report summarized that “Although there was only one carbon bristle brush tested, it had by far the poorest performance.”. The NASA study also tested Thunderon®. The Thunderon® was in laboratory conditions effective in removing dust from the aluminized thermal control surface, but not effective in removing dust from thermal control paint surface. The NASA report indicated that the best brushes for removing particulate were the Zephyr™ fiberglass fingerprint brush and the Escoda™ Nylon fan brush. However, these brushes penetrating the record groove potentially doing more harm than good but are very effective in removing dust that accumulates on the turntable.

Now in all defense I have not used the the Analog Relax™ record brush which uses VI.8.c COREBRID™ B®: A hollow acrylic fiber that is filled with a conductive material manufactured by Mitsubishi Chemical™. This fiber is 0.03 mm (0.0012”/~30 ?m) diameter and its electrical resistance measures between 100 - 10²? cm. Tima has had good luck with this brush to remove surface detritus.

But if the record is well cleaned - how dirty does it get in play? Not much. If you do not over use the stylus, the vinyl does not abrade, its suppose to plastically deform. Diamond dust - if you calculate the weight loss from a diamond stylus it deposits just a few micrograms of a very fine dust/powder. But once you get into the groove, do you honestly believe that the brush bristles are absolutely clean and not abrading or fracturing leave behind residue. So if you stay out of the groove; what develops - it should be a very dry very fine dust/powder which should have no impact to record play. It just blows around. A clean record with reasonable maintenance of cleanliness practices should yield a very clean stylus other than some very fine powder that is easily removed or maybe an occasional fiber. If your stylus is accumulating gunk that should be red flag that something is very wrong.

Enough for today guys,

Neil

Hi Neil,

I see the point.

1. As to why to brush, I have two reasons. First, I must confess I often play dirty records. This is of course the trap Tima mentioned - too elaborate and tedious cleaning leads to playing unwashed records...Second, during the playback there is always some fluff coming down to the surface. Perhaps this is not that important at all, but sometimes this fluff would get stuck to the stylus. This is esp. a problem with a low riding cart like our Decca Reference, where it can get tangled around the diamond (was already removing one). And to my *big* surprise I heard few times the friction of a fluff stuck to the bottom of the Decca against the vinyl...and I was not smoking anything

2. The brushed I used (Audio Quest carbon) was indeed more moving than catching on most occasions. That's why we got the Ramar one. It is a mix of carbon and goat's hair, and has much more bristles. IIRC 12 rows tightly packed against the usual 2 rows separated by a cm or so of the AQ and the similar. This beast really picks stuff. Eventual static is solved by the ion blower which neutralizes any static within few seconds, so no need for advanced conductive bristle materials. The only possible drawback I could think of is the use on unwashed vinyls - the bristle "power" is quite big so it might push the dirt inside the grooves. Thus on dirty vinyls I use it with only minimal pressure.

3. Neil, I wanted to double check the USC power parameter before I damage anything. You mentioned that 150W for 6L is low power and best to use USC at 100%. Looking at Elamsonic specs, their 6L units also have 150W and 12L double that so 300W. As far as I understand what matters is the power per volume of the working fluid. So my unit has (at least on paper) same Watt per Liter as the big Elmasonic. If that is correct, would 100% power setting (150W for 6L) still be safe? A broader question, what is the status of the aledgged HF damage/ roll-off due to USC? If so, has anyone researched what power levels are save at given USC frequencies?

Thanks again,

Jarek

I see the point.

1. As to why to brush, I have two reasons. First, I must confess I often play dirty records. This is of course the trap Tima mentioned - too elaborate and tedious cleaning leads to playing unwashed records...Second, during the playback there is always some fluff coming down to the surface. Perhaps this is not that important at all, but sometimes this fluff would get stuck to the stylus. This is esp. a problem with a low riding cart like our Decca Reference, where it can get tangled around the diamond (was already removing one). And to my *big* surprise I heard few times the friction of a fluff stuck to the bottom of the Decca against the vinyl...and I was not smoking anything

2. The brushed I used (Audio Quest carbon) was indeed more moving than catching on most occasions. That's why we got the Ramar one. It is a mix of carbon and goat's hair, and has much more bristles. IIRC 12 rows tightly packed against the usual 2 rows separated by a cm or so of the AQ and the similar. This beast really picks stuff. Eventual static is solved by the ion blower which neutralizes any static within few seconds, so no need for advanced conductive bristle materials. The only possible drawback I could think of is the use on unwashed vinyls - the bristle "power" is quite big so it might push the dirt inside the grooves. Thus on dirty vinyls I use it with only minimal pressure.

3. Neil, I wanted to double check the USC power parameter before I damage anything. You mentioned that 150W for 6L is low power and best to use USC at 100%. Looking at Elamsonic specs, their 6L units also have 150W and 12L double that so 300W. As far as I understand what matters is the power per volume of the working fluid. So my unit has (at least on paper) same Watt per Liter as the big Elmasonic. If that is correct, would 100% power setting (150W for 6L) still be safe? A broader question, what is the status of the aledgged HF damage/ roll-off due to USC? If so, has anyone researched what power levels are save at given USC frequencies?

Thanks again,

Jarek

3. Neil, I wanted to double check the USC power parameter before I damage anything. You mentioned that 150W for 6L is low power and best to use USC at 100%. Looking at Elamsonic specs, their 6L units also have 150W and 12L double that so 300W. As far as I understand what matters is the power per volume of the working fluid. So my unit has (at least on paper) same Watt per Liter as the big Elmasonic. If that is correct, would 100% power setting (150W for 6L) still be safe? A broader question, what is the status of the aledgged HF damage/ roll-off due to USC? If so, has anyone researched what power levels are save at given USC frequencies?

Jarek:

1. 1st - as written in the book "XIV.1....For ultrasonics there is a minimum power (wattage) necessary to produce cavitation. The higher the frequency, the more power is required. The minimum power required at 40 kHz is reported between 0.3 and 0.5 W/cm² (per transducer radiating surface). As the UCM tank volume increases, less power, measured as W/gal or W/cm³ is required to maintain cavitation throughout the tank. A very small 0.5-gal/1.9-L 40-kHz tank may require 125 W/gal while a 12.75-L/3.4-gal 40-kHz tank may only require 80 W/gal; noting that as the ultrasonic kHz increases so does the power required. There is a limit to increasing power above which no additional benefit is obtained.

2. The specs PP_Elmasonic_P120H_EN.pdf (elma-ultrasonic.com) for the Elmasonic P120H state: Ultrasonic power effective (W) 330 and Ultrasonic peak performance max.(W) 1320. Its a powerful unit. Does your unit have similar detailed info?

3. The KL Audio is 40 kHz and 200W with the transducers pointed directly at the record with a tank volume of only 2.5 L. This is probably the unit that if damage was to occur it would be from this unit. The Degritter is 300W and 1.4L , but is 120kHz so much less risk of damage. KL Audio does mention some proprietary method to eliminate risk of damage, but its still likely the unit that would have caused damage. Bill Hart of the About - The Vinyl Press has a very revealing system and has a very good ear, and has used a KL Audio for some time without any notice of loss of high frequency info. If you read some the older posts at vpiforum.com • View topic - Record cleaning Harry notes that loss of high frequency info was mostly attributed to cleaner residue which others have also noted as a "veiling" of the music.

4. There is no research on the maximum power that is safe at 35-40 kHz other than the ultrasonic power heating the fluid/record to the point the record warps. You should not use UT <35kHz. Can you damage a record with UT, yes? You run it long enough and heat the fluid/record to the point it warps and then continue cleaning for a long enough period you can melt the record especially if you do not spin the record while cleaning, Otherwise, people have been using ultrasonics to clean records for some 50-yrs; just not widely publicized - no blogs/forums back then.

So even 0.2um is better! Ok

The filter I identified is 0.2 um absolute which could be some 25X better than your 0.5 um nominal rated filter. "XIV.18 Filter Cartridges: Filters are rated absolute or nominal. Absolute rated filters will generally remove not less than 99.5% of all particles greater than the rating. Industry standard nominally rated filters will generally remove about 80% of all particles greater than the rating, and generally have a 95% efficiency for particles about 5X the nominal rating. But some nominal rated filters can have nominal efficiency as low as 30% and the 95% efficiency can be as much as 50X the nominal rating. For absolute and nominal rated filters, the vendor should provide a filter efficiency chart that shows the filter performance.".

Good Luck,

Neil

Neil, I wanted to double check the USC power parameter before I damage anything

Here is a convenient chart for comparison of the Elmasonic P-series:

Contrary chart, the P120H is supported at 115-120 V.

Elma now has a new 'S' series that is very similar to the P series but in three main respects, the S series does not offer dual frequency operation, S has 4 ultrasonic transducers compared to the P's 6, and S can be had for almost half the cost of P. David and I use an S120H tank for rinsing.

Tim @tima (and Neil @Neil.Antin ), would you still recommend running the P120H at 70% power? Is that enough or too much?

Neil,

As always very revealing, thank you!

1. So the bigger the tank, the easier is to maintain the cavitation action making bigger tanks more preferable. Had no idea of that.

2. My unit is some cheap GT Sonic P6 with only nominal power (150W) stated, no peak power. IIRC it has 3 transducers (6L). It has been doing a good job though. I'll check now after increasing the power from 75% to 100%. I checked Elmasonic P series (thanks Tima for the info!). Pricey.

3&4 Very interesting info on the HF roll-off issue and the damage risk. So heating is the biggest danger.

BTW, found easier available pump (importing from UK to EU is now not so straightforward after the Brexit) SEAFLO SFDP1-010-040-21 looks like the equivalent of what you mentioned.

As always very revealing, thank you!

1. So the bigger the tank, the easier is to maintain the cavitation action making bigger tanks more preferable. Had no idea of that.

2. My unit is some cheap GT Sonic P6 with only nominal power (150W) stated, no peak power. IIRC it has 3 transducers (6L). It has been doing a good job though. I'll check now after increasing the power from 75% to 100%. I checked Elmasonic P series (thanks Tima for the info!). Pricey.

3&4 Very interesting info on the HF roll-off issue and the damage risk. So heating is the biggest danger.

BTW, found easier available pump (importing from UK to EU is now not so straightforward after the Brexit) SEAFLO SFDP1-010-040-21 looks like the equivalent of what you mentioned.

I've been doing 30 minutes on some albums with really good results.

The GEM Dandy gets groves better but is labor intensive. The issue is the ultrasonic gets rid of hang-nails or rather "hang-vinyl" that are from scratches etc. (that is the black stuff you see in the water after cleaning a bunch of albums I think)

How do I even know that or figure that out? I can clean some albums on the GEM Dandy and they'll play perfect, but if it's got any sort of scratches on it then I pretty much have to run it through the ultrasonic. However only the pop sounds change... that's how I figured it out, and why people were concerned about black residue.

The GEM Dandy gets groves better but is labor intensive. The issue is the ultrasonic gets rid of hang-nails or rather "hang-vinyl" that are from scratches etc. (that is the black stuff you see in the water after cleaning a bunch of albums I think)

How do I even know that or figure that out? I can clean some albums on the GEM Dandy and they'll play perfect, but if it's got any sort of scratches on it then I pretty much have to run it through the ultrasonic. However only the pop sounds change... that's how I figured it out, and why people were concerned about black residue.

Jarek,BTW, found easier available pump (importing from UK to EU is now not so straightforward after the Brexit) SEAFLO SFDP1-010-040-21 looks like the equivalent of what you mentioned.

That pump is an equivalent; its competing against the Shurflo unit as is their entire product line; nice job hunting that down. Couple items - it does not have an ON/OFF switch; easy to work around. The other is the motor shell at thermal cutoff is 185F. That is very high. The Shurflo is 150F. However, for this application the motor should never get anywhere near that temp. Running only intermittent between batches - the motor shell will likely never get above 100F.

Neil

Last edited:

Similar threads

- Replies

- 3

- Views

- 845

- Replies

- 7

- Views

- 2K

- Replies

- 13

- Views

- 2K

- Replies

- 21

- Views

- 3K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |