Fake connectors are an even bigger issue than low life Neutrik, at least those are original.

what do you mean by “fake“ connectors?

Fake connectors are an even bigger issue than low life Neutrik, at least those are original.

what do you mean by “fake“ connectors?

A hell of a lot of people like the way your cables sound, and your prices are more than reasonable. For anyone that likes them they can't lose. You do auditions, so it seems like you can't be totally opposed to choosing by sound.

Dave,

Other than listening, how do we research cables?

Interesting, but a bit too complex for me to follow(...) here is a study made by ESA (European Space Agency) Technical Directorate, ESTEC, Noordwijk, The Netherlands, in regards with the oxidation on silver platted copper cables insulated, with fluorcarbon plastics or aromatic polymide resin and used in aerospace applications, in both Europe and the United States, and have been examined for evidence of red-plague corrosion.

(...)

it also seems that corrosion/oxidation on exposed silver and copper elements, within our electronic components should be of higher concern

Also what about cartridges’ coils and wires which are totally nude? will their sound degrade due to the exposed wires ?

Interesting, but a bit too complex for me to follow.

AFAIK, it is near impossible for us to avoid some oxidation in our domestic environments but, on the bright side, silver oxide is conductive anyway...

But aren't all of the components in our devices exposed (to varying degrees) to air anyway -- as you note, the cartridges being a case in point?

Dave how you have managed to keep the inert gas inside your cables?That link details corrosion in INSULATED wire. Might be even worse if the wire wasn't insulated at all! It also details a type of corrosion that happens in aerospace environments called "red plague" and has nothing to do with any audio application.

Also, the corrosion on silver is not primarily silver oxide, it's silver sulfate. In any case, I've actually built cables with fabric/air dielectric and watched the wire corrode over many years. Silver wire first turns black and then the black coating turns into a powder and starts falling off of the wire. This corrosion is likely a combination of silver sulfate, silver sulphate, silver oxide and even silver chloride. This is not a benign phenomenon as those selling you air dielectric cables will claim.

The issue is air IS a better dielectric and cables sound a little better vs a dielectric that is effective in preventing corrosion, except for inert gas. I have tested inert-gas insulated cables and they sound about the same as air, but you have to put the wire in a sealed tube flushed with the gas. Both getting all the air out and inert gas in, as well as sealing the tube is difficult. This is why many cable companies will sell you cables with cotton, silk or "air" dielectric. I would point out that at least one company selling wire with a silk dielectric also impregnates the silk with mineral oil, which coats the wire and prevents corrosion. This was probably done in times before we had plastics.

Also, it is true that the parts in our components are uninsulated, but the wire is always tinned. Tin won't corrode, it's the main component of solder, so when you tin a wire with solder you are also preventing corrosion. Also, when you have a small amount of wire exposed to air near terminations, this can be dealt with in a few ways, you can use a conformal coating, which is like a thin potting compound that's painted on, or you can use a product like Furutech Nano-fluid, which is what I use, or you can simply make sure the wire is tinned, but this may not be sufficient right near where the insulation is stripped from the wire because it's hard to get solder to flow right up to the insulation.

I know it is “not done“ and asking for trouble to call out the frauds, Dave. Pitty. For me, yes real value and technology matter. I bought several furutech NCF nanoflux power cables and I couldn’t be happier: soundwise and pride of ownership. I think their reputation is well earned.Here's an example of look-alike plugs, these are copies of the Furutech CF-601 and CF-602. They cost $12.74 for all 4 plugs. I've seen these and other similar plugs used on cables that cost thousands. I've never heard ANYONE call them out on it. I'm not naming names because it's not worth the hassle, I'd rather just concentrate on what I do... but I also hate to see people mislead, so before you spend 5-figures on a set of brand new cables with look-alike connectors you may want to make sure you're getting what you think you're getting. A $5 plug or a $145 plug...

Here's the real deal, these cost $556 for 2 of each:

Unfortunately, this is VERY common. There are fakes or look-alikes for every high end plug and even cable can be fake. When cable like Furutech DPS-4 goes for $450/m you can be assured it will be counterfeited eventually. Component manufacturers have to be very careful of fake capacitors, resistors, etc. It's a bigger issue than many would believe. Dishonest people buy products from Alibaba and resell them here. Occasionally they are the same, but possibly made on a midnight production run and carried out the back door so the owner foots the bill for everything and the seller has zero into it.

Gregadd is correct, Caveat Emptor is the way it works, but I think with cables many are unaware of what to look out for. It's considered normal for cable companies to be secretive, which is understandable because not much is known about why cables sound different, but OTOH it's certainly allowed for some dubious design, dubious value, dubious ethics to exist. It's not just cable though, I'm sure many remember that Lexicon disc player that was an OPPO dropped into a different chassis with no other mods except a much larger pricetag.

So anyways, my take is honest is good, poor design and "cheaping out" is not. Siltech may be pricey, but they are a good product and they are honest. The Triple Crown could possibly be the best power cable on the market for many people and you get the benefit of a local dealer's service, so for some that's priceless.

Unfortunately I don't have the desire to attempt to compare patiently and meticulously the sounds of different cables between every pair of components. This is what I think is required, if one is going to make informed and educated decisions to implement one's subjective sonic preferences when connecting each pair of components. (This means I do not believe in the view that an entire loom of one brand and model of cable is necessarily the sonically correct way to go. Of course it is the clean and easy way to go.)

I have special respect for a company like Cardas which, I believe, extrudes its own wire and winds its own cable configurations and makes its own cable components.

There are also other aspects that can condition what we want to listen in our system - distribution, friendships, trust and, in my case, re-sale value and ease of sale in case I want to move to next cables. The nice thing about cables is that trying them is supposed to be a simple, and I want to keep it that way.

I'd look into the cable's materials and construction. While there are a lot of elements of cable design that are proprietary, it's also possible to provide a pretty decent amount of information without giving every aspect of the design away. And even if you do, I've found that most folks are completely uninterested in their competition's offerings, because of course their own are better.

(...)

Francisco, I noticed you have transparent audio cables. In light of what you write above, what do you think about resale value and ease of sale in the case of these cables? I found it rather difficult because of the recalibration requirements and need to coordinate with the factory and the dealership to get all that done. It is complicated further because the service does not extend beyond the original owner unless you buy the service for additional cost.

Dave how you have managed to keep the inert gas inside your cables?

because in my industry (another cost-no-object industry with real engineering) it’s impossible, even with high engineered means and certified sealed tanks, we have to add inert gas every three days.

I have heard same things about helium at stealth cables and it’s strange because I can’t keep this gas in my diving bottles for long

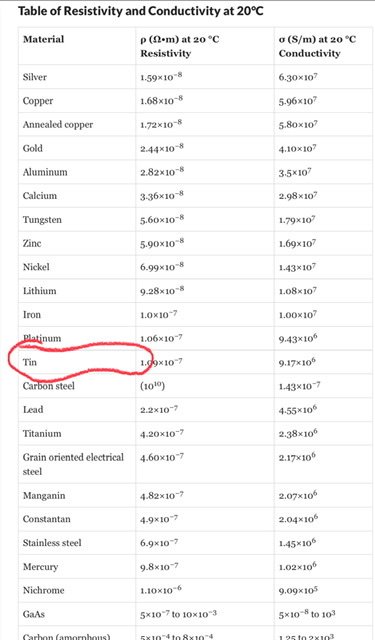

p.s. Quoted from an article “...Tin is an electrical conductor. But its volumetric resistivity is significantly higher than that of copper, so you won't see it used for wires, circuit board traces, bus bars, etc. ... tin is one of the main ingredients in electrical solder....”

View attachment 74206 View attachment 74208 View attachment 74209

p.s2 Tin actually is considered as semi conductor in physics

I must say I disagree on this aspect. Cables are not jewelry , we risk paying for expensive details that are not relevant for sound. Manufacturers will not release accurate information mostly because it would become a poor marketing decision - they need magic and pseudo science to sell. It would not allow them to create classes in their products.

Just MHO, but I think it is not just the materials, but mostly the way they are processed. And although it involves a lot of technology and engineering, most cable development knowledge is empirical and extremely personal. It is not easy to valuate with confidence such aspect.

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Co-Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |