Studer C37, rewind tape tension.

- Thread starter sigitask

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thank you! bearings is allready changed, but it not helps. Are you sure that there is not DC braking? I measured DC on motor by rewinding, it is 9v DC. Also when I disconnect motor from electronic, tape tension goes down.Since the motors are not electrically braked when winding, the bearings of the motors and pulleys could be stiff. If these have never been exchanged, they should definitely be exchanged. I had installed Skf E2 bearings.

Thank you for advice of SKF E2 bearings. Its low friction bearings, and it is important in tape recorders. I will try it.Thank you! bearings is allready changed, but it not helps. Are you sure that there is not DC braking? I measured DC on motor by rewinding, it is 9v DC. Also when I disconnect motor from electronic, tape tension goes down.

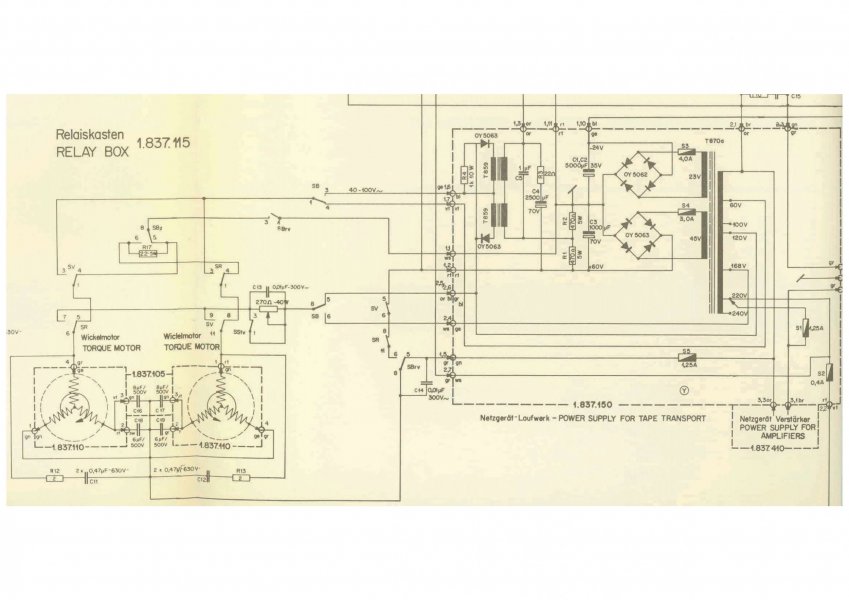

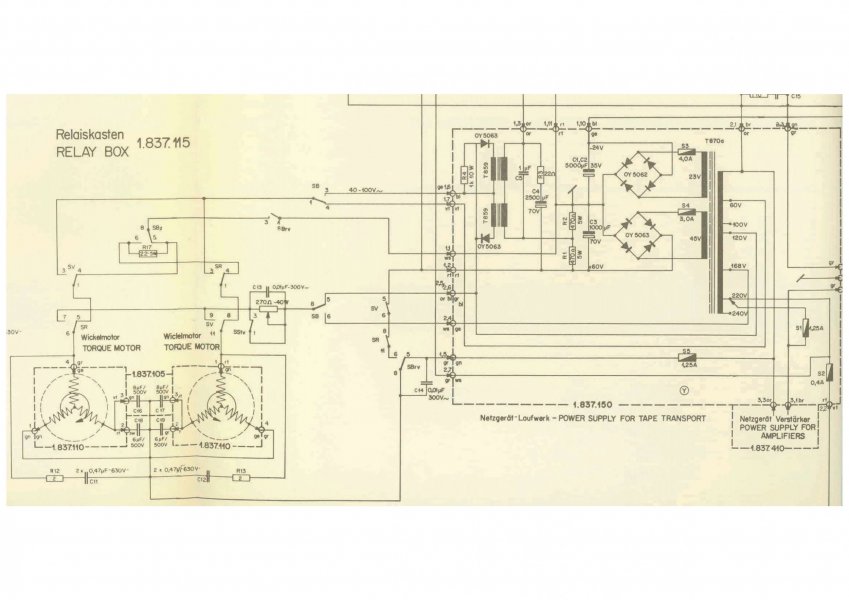

You can see on the schematics, Laufwerk Schema, that the Transistor ASZ18 is regulating DC for Motors. It is controlled in winding with R14, Abgleich Bremszug beim Schnellwickeln. I think there is some DC also during winding (i will measure this in a few days) I just Could not feel it with my hand...

Last edited:

I had time to check Voltage on the right Torque Motor.

Stop - 67V DC measured to Ground

Play - 55V (more break) to 65V (less break), depends on Tape tension Balance

Winding forward - 62V

Winding back - 52V

The internal Meter, Position 5 - Bremsstrom stands at 1 during winding.

Short Break after Winding about zero Volt.

I hope this helps.

Stop - 67V DC measured to Ground

Play - 55V (more break) to 65V (less break), depends on Tape tension Balance

Winding forward - 62V

Winding back - 52V

The internal Meter, Position 5 - Bremsstrom stands at 1 during winding.

Short Break after Winding about zero Volt.

I hope this helps.

Thank you! I measured to. In Winding back mode is it 53V more less, as yours. And this voltage not depended on Tape tension balance position. I investigated schematic, and found that relay SB can disconnect tension balance from ASZ18 basis. And this voltage on emitter (in back wind mode it is connected to motor) is set by resistors on basis R3 and R14. So i will try to make tension less to increase resistor R14. May you check on your machine, if this voltage on motor in Back Winding mode not depends on Tape Tension Balance?I had time to check Voltage on the right Torque Motor.

Stop - 67V DC measured to Ground

Play - 55V (more break) to 65V (less break), depends on Tape tension Balance

Winding forward - 62V

Winding back - 52V

The internal Meter, Position 5 - Bremsstrom stands at 1 during winding.

Short Break after Winding about zero Volt.

I hope this helps.

Thank you!Tension balance is undependent in winding mode, SB relay works as you say.

Hi there,

I know it's an old thread but I'm searching for some help/advice about reel tension on my J37. There are some differences with the C37 regarding the tape tension which is regulated by a magnetic amplifier but I guess the philosophy remains the same. I'm not a tech so I tried to understand how it works the best I could...

Issue is: REW is perfectly within stock timing value, FF looks a bit slower and is progressively slowing down from 12/15' to end up with stopping at 22/24'.

1- At the time the issue initially appeared, FF spooling time was ok just after powering on the machine and the slowing down thing occurred after the machine warmed up. This points to some electrical component or cap I think. Now, it occurs whatever the machine is cold or hot.

2- Left reel tension in REW: 700g. Right reel tension in FF: 450g

3- I could have a check with the motors cables swapped: issue gets reversed then, right motor is ok, left motor is slowing down and stops.

4- I could get a better FF behaviour when replacing the 8µF C17 with a 10µF or even better with a 12µF. This was just a workaround and I went back to the regular 8µF to avoid any damage.

Here are the result of my thoughts:

- Motors are not faulty

- The issue could be a component close to the motors, after the relays as FF only is involved and REW is working perfectly. Most further components would affect both modes if I don't miss anything.

- There are 2 power caps in parallel mode per motor on the J37: C16+C18 (L), C17+C19 (R).

C16 & C17 are 8µF and located under the deck close to their respective motors and share the same cable and plug (and were swapped together with their motors thereby when checking the motors swap).

C18 & C19 are 6µF and located on the relay box. Which gives 14µF as stamped on motors.

Here's what I'm thinking: if C19 is faulty and doesn't deliver any voltage, resulting a total 8µF capacitance for the take up motor, I guess it should cause the issue I'm encountering. Could I be right or do I miss something?

Just to add, the machine was mint and very low hours, it had been fully maintained, recapped, bearings etc. The relays remained unchanged, I had some tests with new ones or swaps with no change.

Thank you for your help!

Alain

I know it's an old thread but I'm searching for some help/advice about reel tension on my J37. There are some differences with the C37 regarding the tape tension which is regulated by a magnetic amplifier but I guess the philosophy remains the same. I'm not a tech so I tried to understand how it works the best I could...

Issue is: REW is perfectly within stock timing value, FF looks a bit slower and is progressively slowing down from 12/15' to end up with stopping at 22/24'.

1- At the time the issue initially appeared, FF spooling time was ok just after powering on the machine and the slowing down thing occurred after the machine warmed up. This points to some electrical component or cap I think. Now, it occurs whatever the machine is cold or hot.

2- Left reel tension in REW: 700g. Right reel tension in FF: 450g

3- I could have a check with the motors cables swapped: issue gets reversed then, right motor is ok, left motor is slowing down and stops.

4- I could get a better FF behaviour when replacing the 8µF C17 with a 10µF or even better with a 12µF. This was just a workaround and I went back to the regular 8µF to avoid any damage.

Here are the result of my thoughts:

- Motors are not faulty

- The issue could be a component close to the motors, after the relays as FF only is involved and REW is working perfectly. Most further components would affect both modes if I don't miss anything.

- There are 2 power caps in parallel mode per motor on the J37: C16+C18 (L), C17+C19 (R).

C16 & C17 are 8µF and located under the deck close to their respective motors and share the same cable and plug (and were swapped together with their motors thereby when checking the motors swap).

C18 & C19 are 6µF and located on the relay box. Which gives 14µF as stamped on motors.

Here's what I'm thinking: if C19 is faulty and doesn't deliver any voltage, resulting a total 8µF capacitance for the take up motor, I guess it should cause the issue I'm encountering. Could I be right or do I miss something?

Just to add, the machine was mint and very low hours, it had been fully maintained, recapped, bearings etc. The relays remained unchanged, I had some tests with new ones or swaps with no change.

Thank you for your help!

Alain

Last edited:

Similar threads

- Replies

- 23

- Views

- 3K

- Replies

- 16

- Views

- 1K

- Replies

- 1

- Views

- 930

Members online

- abeidrov

- BR549

- SirVeza

- leszek

- patleguen77170

- MJD Michigan

- riwin_h

- Klonk

- Jpowell

- hchilly

- DarrellC

- Low325

- daveoo

- dmm714

- Zigis

- RCanelas

- bonzo75

- SOS

- engadin

- joaovieira

- Juiced

- audlike

- simorag

- Young Skywalker

- Rob77

- KAZI16

- rpk

- waterlelies

- Gregm

- Opabin

- Ken_loves_classical

- davros

- drjimwillie

- Antonio66

- thase13

- SlapEcho

- nkjtbushwood

- sbnx

- mmhifi

- tomas329

- DLS

- WildPhydeaux

- Rexp

- Michael S.

- alexz

- bryans

- John T

- Stormcat

- mlhotts

- Argonaut

Total: 1,498 (members: 67, guests: 1,431)

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Co-Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |