Hello STUDER experts:

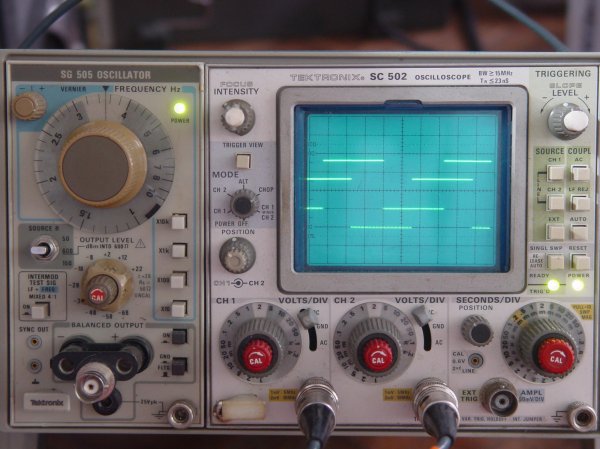

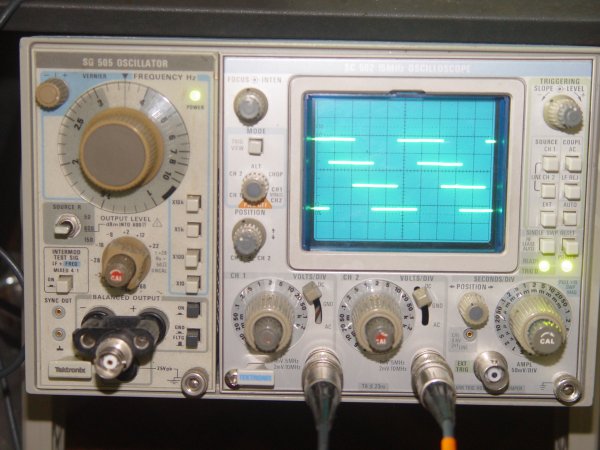

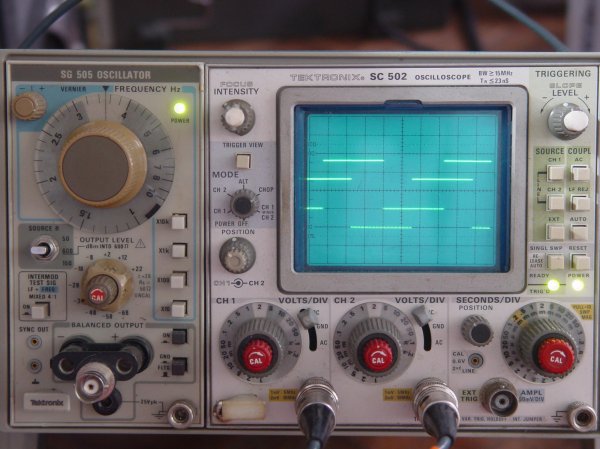

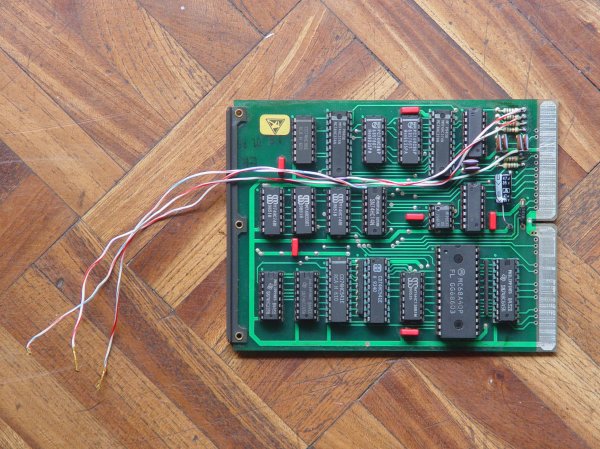

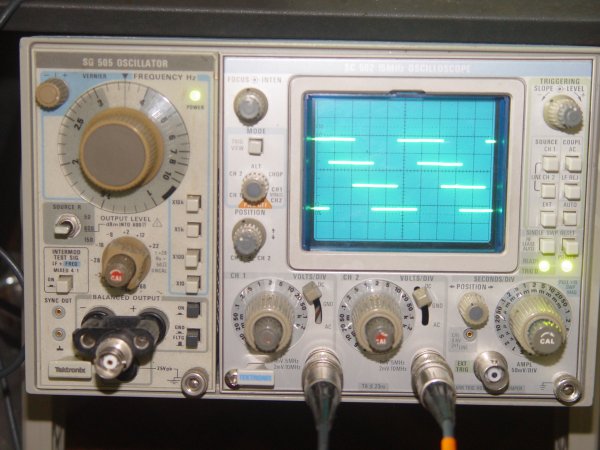

Recently my STUDER A820 developed a problem which prevented it from FF/rewinding/library winding; soon after the command was issued an error message INCORRECT RADIUS MEASUREMENT appeared briefly; then tape tension dropped, tape unloaded. According to the manual the culprit would be tacho sensors (Spooling motor?). Although I do not have an extender board 1.820.799.00, I managed to soldered wires from six resistors after pin 1~4, 7,8 on TD Couter/timer board 1.820.761.82, which represents two 90 degrees out ot phase-50% duty cycle square wave from left/right tacho sensors of left/right spooling motors and the motion sensor. The duty cycle of each of six square wave signal was measured/adjusted by monitoring it through a scope.

Problem persists.

Other aspests of the tape handling of this A820 seemed to be O.K.

Currently configuration:

SM-DRV: 820.759.84

CAP-CTR: 820.764.28

CAP-IF: 820.727.00

TD-PER: 820.762.81

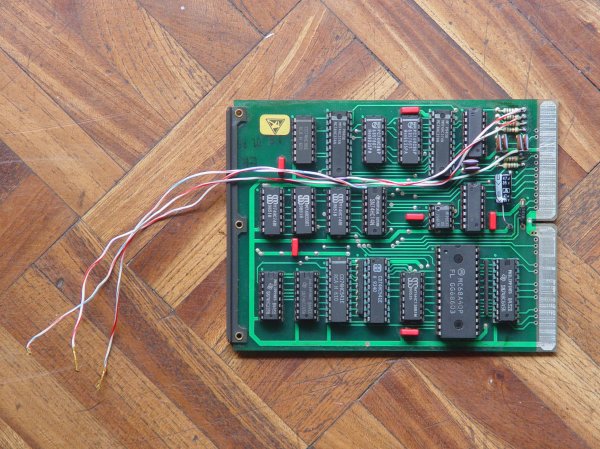

TD-C/T: 820.761.82

SM-CTR: 820.760.82

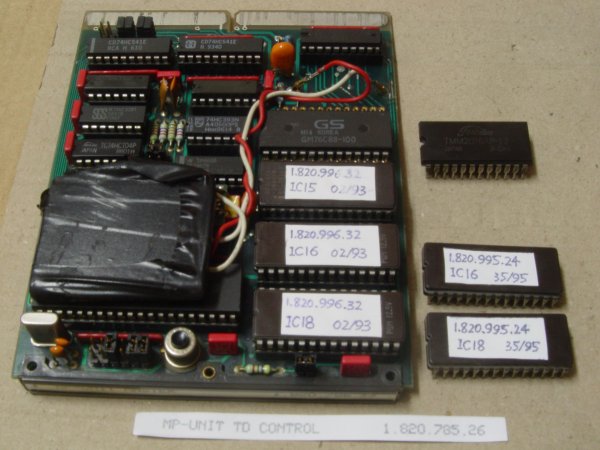

TD-MPU: 820.785.26

TD-S IF: 820.763.83

M-S IF: 820.753.82

M-MPU: 820.786.33

M-PER: 820.728.81

Firmware: Master MPU: 1.820.996.32: 02/93; TD-MPU: 1.820.995.24; 35/95; Capstan Control: 1.820.994.27; 10/92

After firmware update this A820 operated half a year without any problem.

Any suggestion?

Yeun-Jung Wu

Recently my STUDER A820 developed a problem which prevented it from FF/rewinding/library winding; soon after the command was issued an error message INCORRECT RADIUS MEASUREMENT appeared briefly; then tape tension dropped, tape unloaded. According to the manual the culprit would be tacho sensors (Spooling motor?). Although I do not have an extender board 1.820.799.00, I managed to soldered wires from six resistors after pin 1~4, 7,8 on TD Couter/timer board 1.820.761.82, which represents two 90 degrees out ot phase-50% duty cycle square wave from left/right tacho sensors of left/right spooling motors and the motion sensor. The duty cycle of each of six square wave signal was measured/adjusted by monitoring it through a scope.

Problem persists.

Other aspests of the tape handling of this A820 seemed to be O.K.

Currently configuration:

SM-DRV: 820.759.84

CAP-CTR: 820.764.28

CAP-IF: 820.727.00

TD-PER: 820.762.81

TD-C/T: 820.761.82

SM-CTR: 820.760.82

TD-MPU: 820.785.26

TD-S IF: 820.763.83

M-S IF: 820.753.82

M-MPU: 820.786.33

M-PER: 820.728.81

Firmware: Master MPU: 1.820.996.32: 02/93; TD-MPU: 1.820.995.24; 35/95; Capstan Control: 1.820.994.27; 10/92

After firmware update this A820 operated half a year without any problem.

Any suggestion?

Yeun-Jung Wu

Last edited: