Hey guys,

as my interest in audio startet in 1987, I read a lot of magazines (I still have them all, meters of Stereo, Audio, Stereoplay, Das Ohr, Hifi Exclusiv (Germany), Audio&Techniek, Homestudio, HVT (Netherlands), Hifi Choice, What Hifi (UK) and some The Absolute Sound (when I could get hold of them)

Sometimes in these magazines there where products that where awesome. For me one of them was the Dynavector DV505. I loved the looks and it had reference status back then.

I went to a lot of hifi shows from then till around 2003. I can't remember I ever saw one DV-505 in person.

The build of my Garrard 401 is documented here. I was using a Helius Aurora in 9" version which is a bit short for the Garrard. Also I didn't like the looks of it besides the 401. Still the Helius Design Aurora is a great tonearm, with great service from Geoffrey.

I was thinking about a SME 3012, Groovemaster etc. But then I saw a pic of the Dynavector and was smitten.

Here in Germany the arm comes up once in a while, but didn't have the luck to get hands on one. Till 2 weeks ago. There was a tonarm which was almost complete. Original headshell missing, template missing, but including the Dynavector Lift DV3a, an Orsonic AV1 headshell, an Audio Quest Red Dragon phono cable and a base for a Micro Seiki. But there was work to do: the original internal tonearmcable was broken and the seller tried to replace it and failed at the small arm.

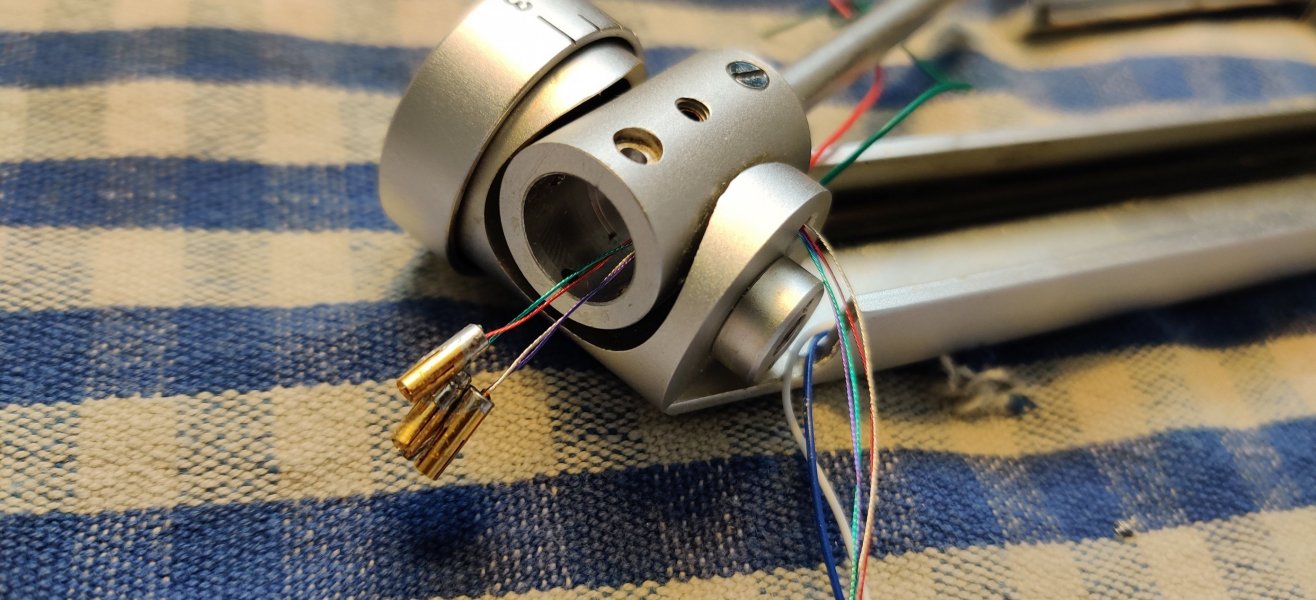

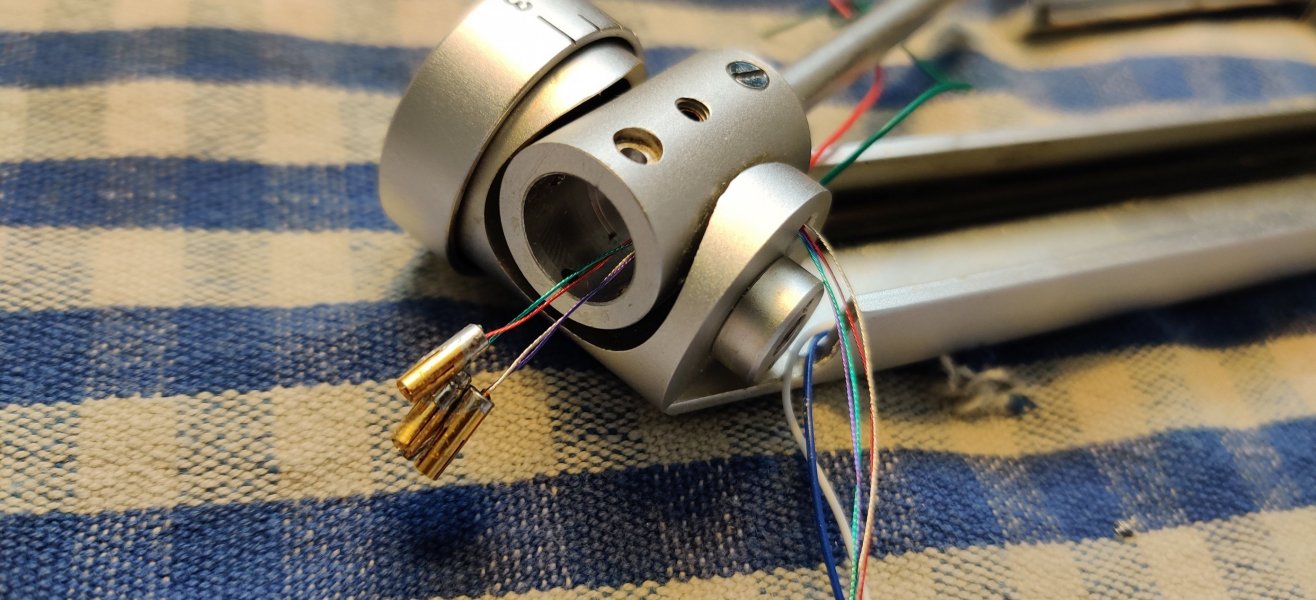

Actually it is not that difficult to replace the cable. So I ordered Van Den Hul MCS 150m internal cable (all 4 internal cable should be max 0,6mm diameter to fit through the small holes). After thorough cleaning and trying to understand a tonearm I'd never seen before, I started working on it:

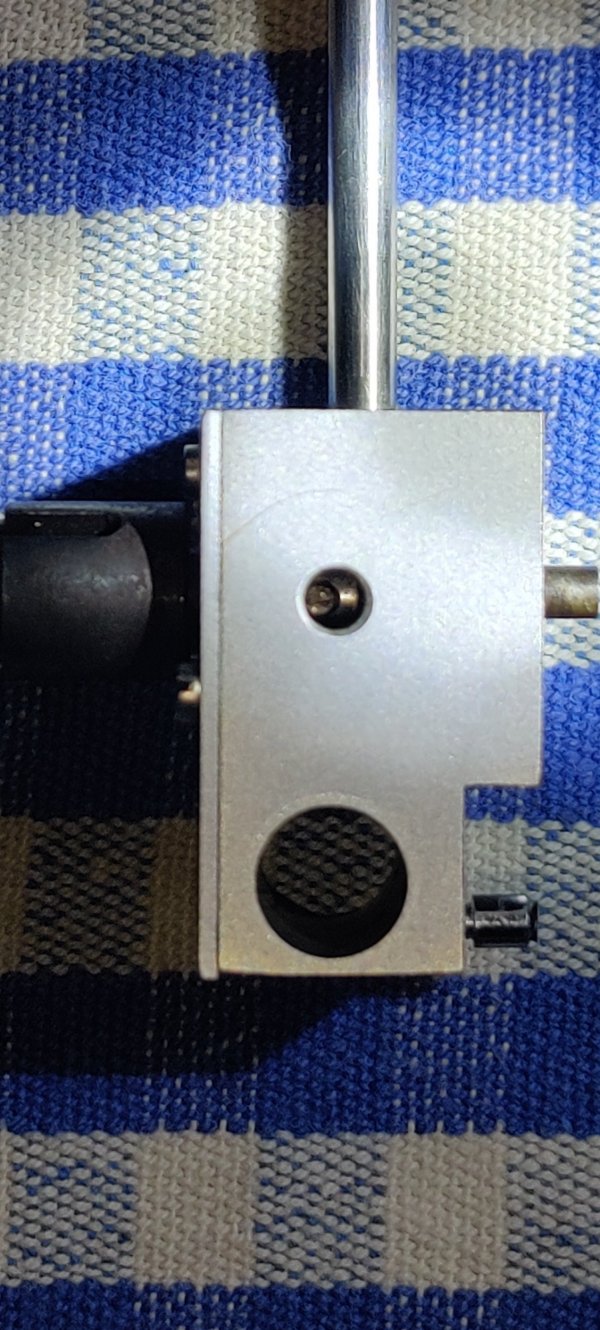

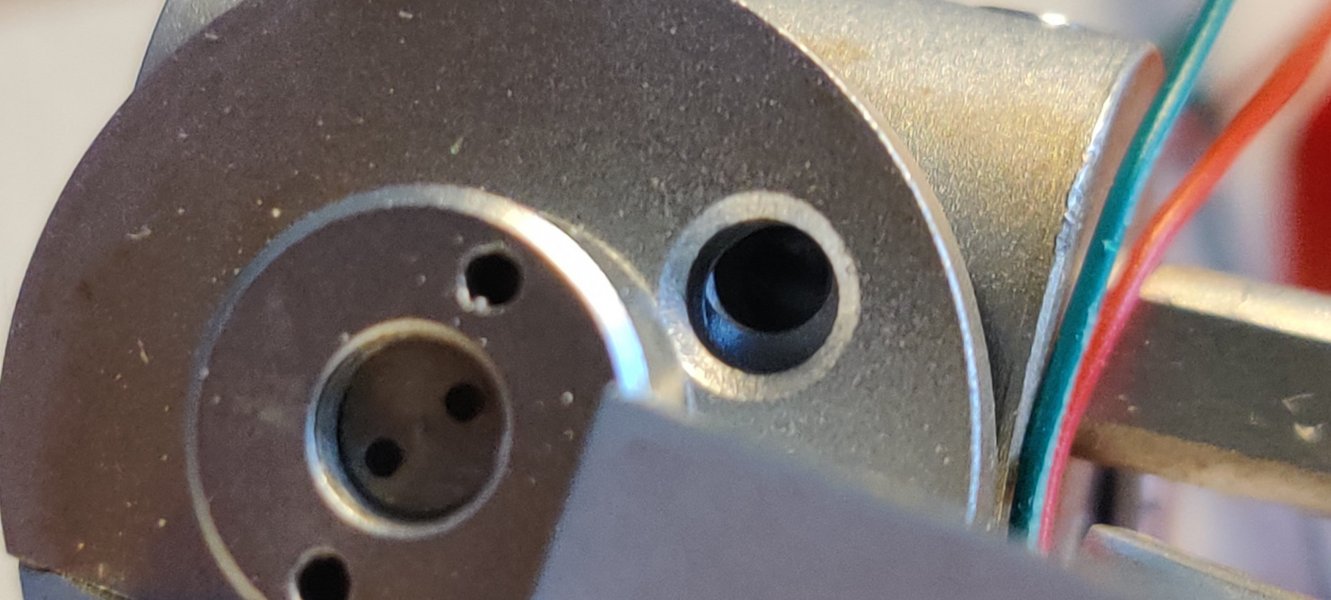

After pulling in a stronger cable (wiggle it a bit till it goes around the corner), I pulled the 4 MCS150 cables through the little hole at the front of the small arm. The SME connector needs to be removed for this, which is just one little screw. Make shure the connectors visible in second pic are max 6mm long, as longer ones will not fit. Soldering the very small van den Hul cables is easy. The isolaton melds at soldering the end. The cables are very rugged also.

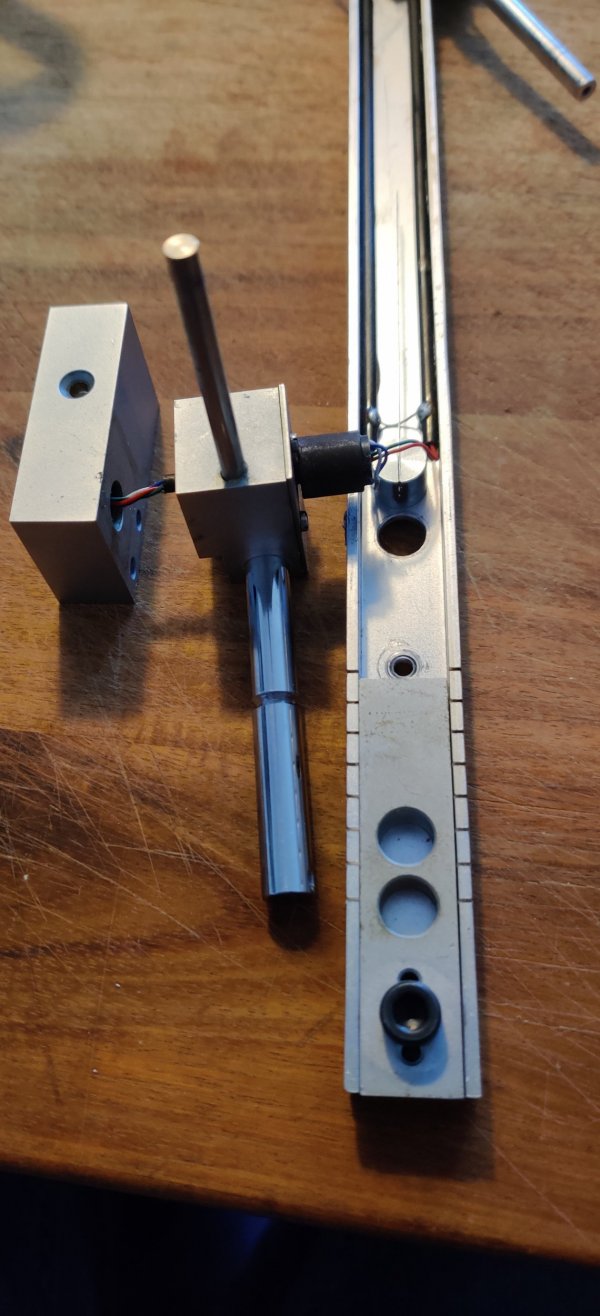

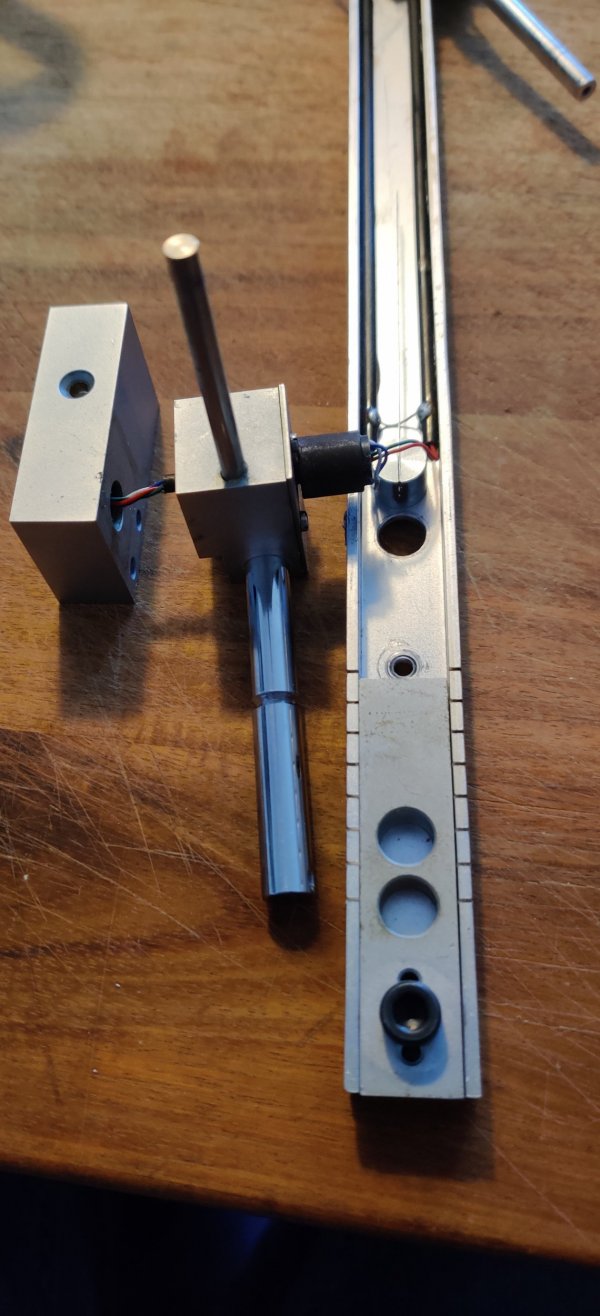

In the long arm, go through the channel which is on the side of the turntable platter. Sometimes left and right channel are seperated in the 2 channels, but thats not necessary.

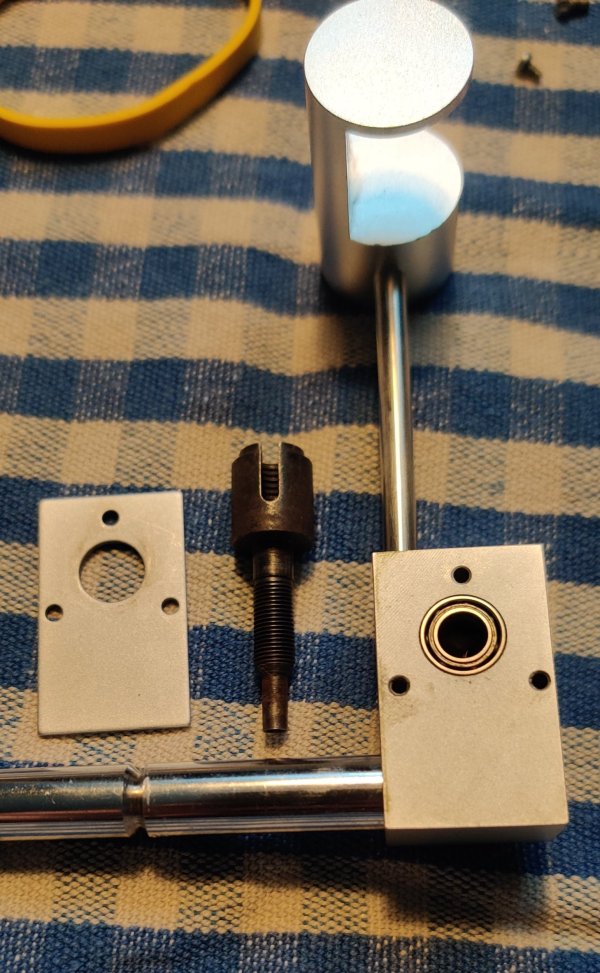

When removing the top 2-hole screw from the top of main arm (which is a pain in the @ without the right tools, as you can see at most arms, which are scratched), you can see the mainbearing through which the cables are going to the SME 5p connector in the base of the arm. No real problem here. Just route the armwire from the armchannel to the bearing hole.Solder it to the SME 5p connector.

After making a new armboard for the tonearm it was quite easy to put the arm at the right distance to the spindle. I reproduced the template which was missing, which helps immensely with alignment of the arm and the cartridge. I will post details when I have made pics of the template.

The Orsonic AV1 headshell was demolished by someone. The pins from the headshell to the cartridge were bent in a way that I was not able to restore them, so I soldered some MCS150 to these pins. Not looking good, but I think the black Orsonic doesn't look very good with my setup. We will find another solution once...

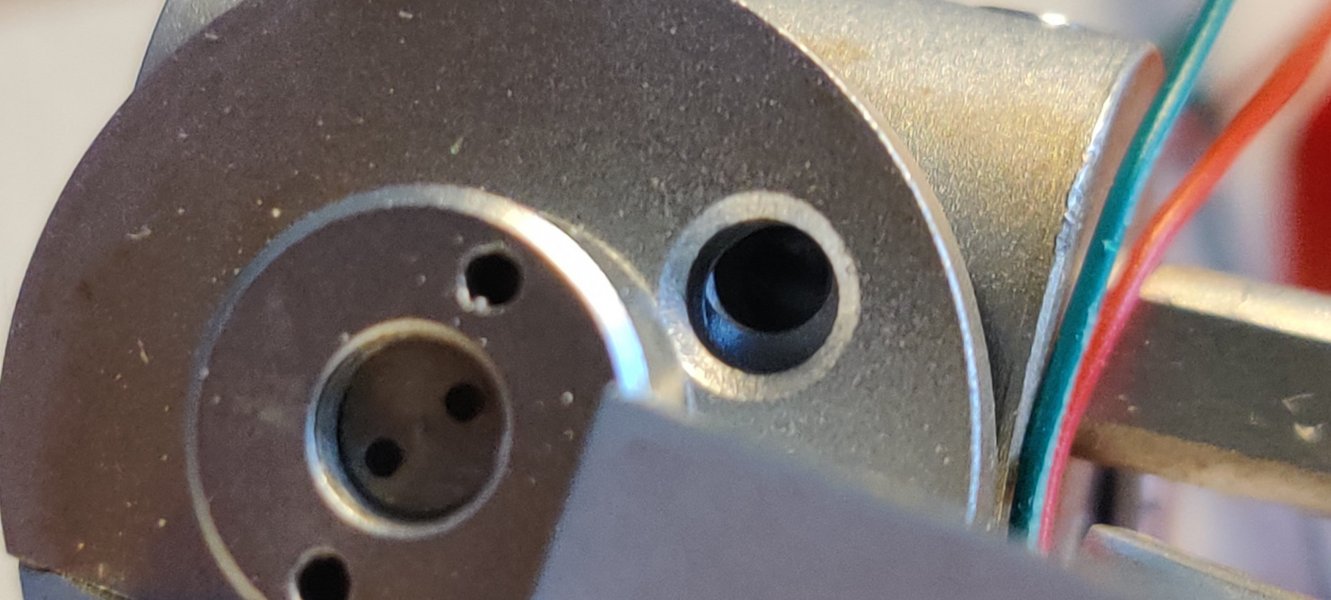

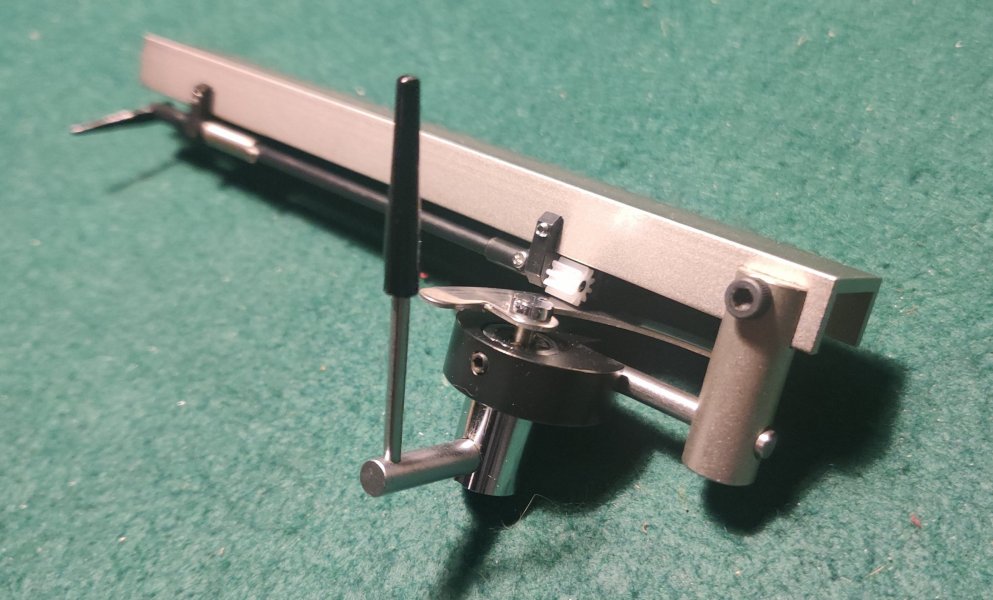

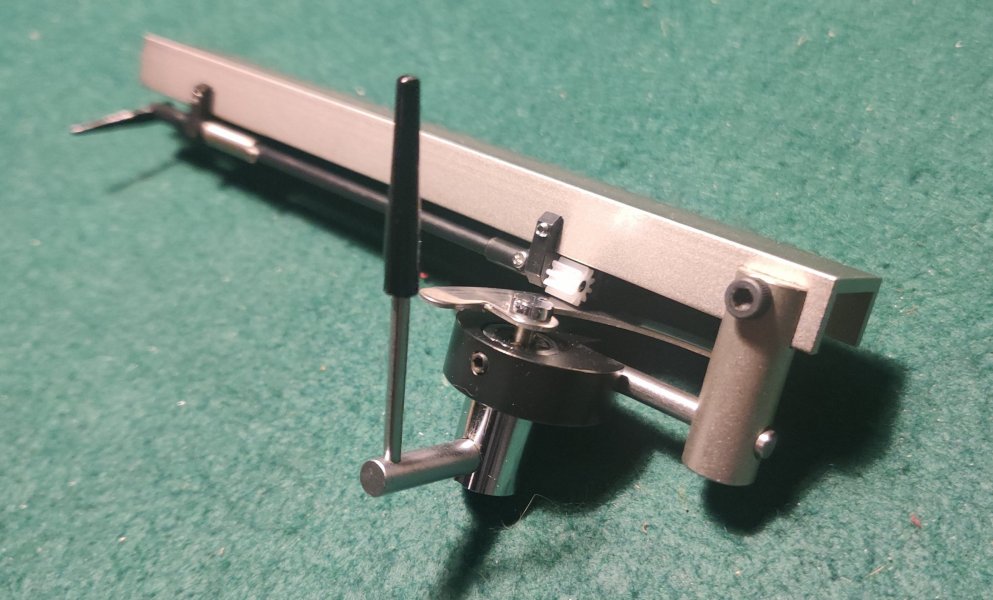

The Dynavector DV3a armlift also came with my purchase. The gear and the well were missing. I found out with help of someone in the "analogforum.de" that this gear measures 6mm diameter, 5mm stark, has 10 tooth and a well of 2mm. Found these in the internet and here is what it looks now, mounted on the "dummy arm" originally supplied;

I need to install the lift on the arm, as it is quite unusual to handle the arm without lift, although in all this years I didn't use a lift at all... Maybe it is just getting used to it.

Now as the arm is installed I could listen to it.

This tonearm sounds so incredibly good, with very stable positioning, much enhanced spacial information, more detail and bass is much better defined. It is not as powerfull as the Aurora in the bass region. Also the realism of 3d is enhanced. At times it is quite breathtaking. Never heard cymbals this lifelike on my system. Macro dynamics are great as are micro dynamics and when the music gets fuller and fuller, it doens't get muddied up.

All I can say is that I am very happy!!

Remco

as my interest in audio startet in 1987, I read a lot of magazines (I still have them all, meters of Stereo, Audio, Stereoplay, Das Ohr, Hifi Exclusiv (Germany), Audio&Techniek, Homestudio, HVT (Netherlands), Hifi Choice, What Hifi (UK) and some The Absolute Sound (when I could get hold of them)

Sometimes in these magazines there where products that where awesome. For me one of them was the Dynavector DV505. I loved the looks and it had reference status back then.

I went to a lot of hifi shows from then till around 2003. I can't remember I ever saw one DV-505 in person.

The build of my Garrard 401 is documented here. I was using a Helius Aurora in 9" version which is a bit short for the Garrard. Also I didn't like the looks of it besides the 401. Still the Helius Design Aurora is a great tonearm, with great service from Geoffrey.

I was thinking about a SME 3012, Groovemaster etc. But then I saw a pic of the Dynavector and was smitten.

Here in Germany the arm comes up once in a while, but didn't have the luck to get hands on one. Till 2 weeks ago. There was a tonarm which was almost complete. Original headshell missing, template missing, but including the Dynavector Lift DV3a, an Orsonic AV1 headshell, an Audio Quest Red Dragon phono cable and a base for a Micro Seiki. But there was work to do: the original internal tonearmcable was broken and the seller tried to replace it and failed at the small arm.

Actually it is not that difficult to replace the cable. So I ordered Van Den Hul MCS 150m internal cable (all 4 internal cable should be max 0,6mm diameter to fit through the small holes). After thorough cleaning and trying to understand a tonearm I'd never seen before, I started working on it:

After pulling in a stronger cable (wiggle it a bit till it goes around the corner), I pulled the 4 MCS150 cables through the little hole at the front of the small arm. The SME connector needs to be removed for this, which is just one little screw. Make shure the connectors visible in second pic are max 6mm long, as longer ones will not fit. Soldering the very small van den Hul cables is easy. The isolaton melds at soldering the end. The cables are very rugged also.

In the long arm, go through the channel which is on the side of the turntable platter. Sometimes left and right channel are seperated in the 2 channels, but thats not necessary.

When removing the top 2-hole screw from the top of main arm (which is a pain in the @ without the right tools, as you can see at most arms, which are scratched), you can see the mainbearing through which the cables are going to the SME 5p connector in the base of the arm. No real problem here. Just route the armwire from the armchannel to the bearing hole.Solder it to the SME 5p connector.

After making a new armboard for the tonearm it was quite easy to put the arm at the right distance to the spindle. I reproduced the template which was missing, which helps immensely with alignment of the arm and the cartridge. I will post details when I have made pics of the template.

The Orsonic AV1 headshell was demolished by someone. The pins from the headshell to the cartridge were bent in a way that I was not able to restore them, so I soldered some MCS150 to these pins. Not looking good, but I think the black Orsonic doesn't look very good with my setup. We will find another solution once...

The Dynavector DV3a armlift also came with my purchase. The gear and the well were missing. I found out with help of someone in the "analogforum.de" that this gear measures 6mm diameter, 5mm stark, has 10 tooth and a well of 2mm. Found these in the internet and here is what it looks now, mounted on the "dummy arm" originally supplied;

I need to install the lift on the arm, as it is quite unusual to handle the arm without lift, although in all this years I didn't use a lift at all... Maybe it is just getting used to it.

Now as the arm is installed I could listen to it.

This tonearm sounds so incredibly good, with very stable positioning, much enhanced spacial information, more detail and bass is much better defined. It is not as powerfull as the Aurora in the bass region. Also the realism of 3d is enhanced. At times it is quite breathtaking. Never heard cymbals this lifelike on my system. Macro dynamics are great as are micro dynamics and when the music gets fuller and fuller, it doens't get muddied up.

All I can say is that I am very happy!!

Remco

Last edited: