Does it come with a quick start user guide?

Ampex electronics for the best possible sound

- Thread starter RogerD

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

That's pretty funny

I've never seen that deck before...what is it

Nor I. OK, what is it?

Tom

It's a good thing - I don't know anyone in Hungary.

Ah...thanks, Myles

Well, the first thing that must be accomplished is to have the head wired out

This was their studio machine but from what I read, their consumer machines were the biggest sellers in the Eastern Bloc.

Thanks, Myles. Interesting machine.

Tom

This one appeared in 1992 and was the last of Mechlabor's.

http://oi59.tinypic.com/2pobfon.jpg

Digital audio was very aggressive in that period and it never went into production. This is a prototype as visible from the anonymous and extremely simplified keyboard (not a scientific calculator anymore).

http://oi59.tinypic.com/2pobfon.jpg

Digital audio was very aggressive in that period and it never went into production. This is a prototype as visible from the anonymous and extremely simplified keyboard (not a scientific calculator anymore).

Studio machines, required maintenance....

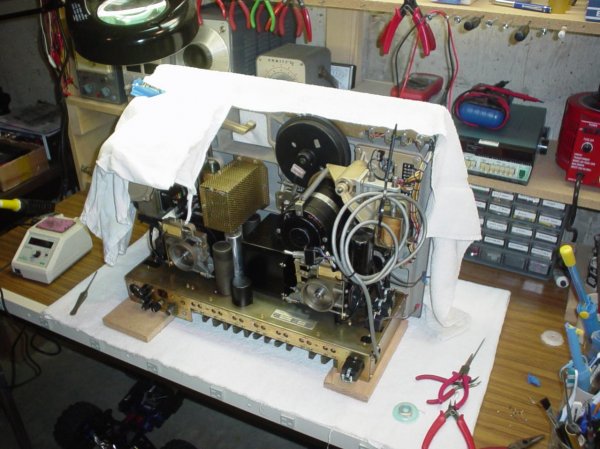

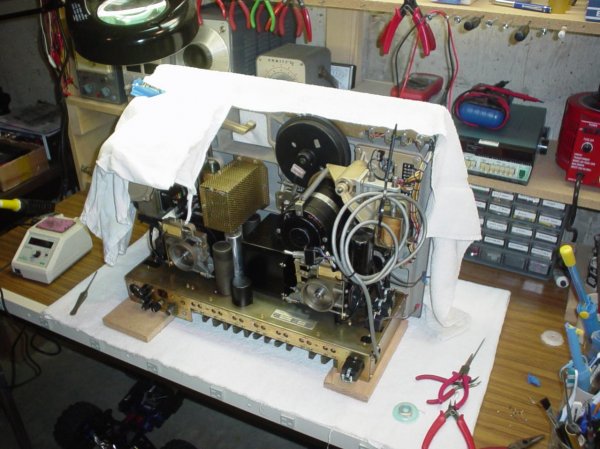

Working on one of my Ampex transports today had me thinking about the true cost of ownership when it comes to the larger studio machines. There are occasional expenses that come up such as head work, which can be significant, although given the limited use these machines now see compared to what they did in the studio, you'd expect to get excellent service life out of new or reworked heads. I don't rebuild my own motors, did it once and it was a real pain. Most other aspects of repair and maintenance I handle myself, including the need to replace a speed switch and do some general PM on the MR70 below:

It takes two people to remove the transport from the rack and drag it down to my workshop, basically an evenings work. Replacing the switch, lets see....started around 6am, finished up 10pm, so that's a whole day, but still managed to get everything done it was longing for. Putting the machine back into the rack will take another evening. Then it's general adjustments in place, idler, brakes, run the EQ just for kicks. I don't go through this routine often, but when I do the time really adds up. Granted, the machine in the picture is an example of one of the more difficult studio machines to work on, but they all take an occasional effort to keep up.

Eh, it's undertakings like this that make tape all the more enjoyable.

Tom

Working on one of my Ampex transports today had me thinking about the true cost of ownership when it comes to the larger studio machines. There are occasional expenses that come up such as head work, which can be significant, although given the limited use these machines now see compared to what they did in the studio, you'd expect to get excellent service life out of new or reworked heads. I don't rebuild my own motors, did it once and it was a real pain. Most other aspects of repair and maintenance I handle myself, including the need to replace a speed switch and do some general PM on the MR70 below:

It takes two people to remove the transport from the rack and drag it down to my workshop, basically an evenings work. Replacing the switch, lets see....started around 6am, finished up 10pm, so that's a whole day, but still managed to get everything done it was longing for. Putting the machine back into the rack will take another evening. Then it's general adjustments in place, idler, brakes, run the EQ just for kicks. I don't go through this routine often, but when I do the time really adds up. Granted, the machine in the picture is an example of one of the more difficult studio machines to work on, but they all take an occasional effort to keep up.

Eh, it's undertakings like this that make tape all the more enjoyable.

Tom

I found an MR70 4T 1/2" here in Sweden(Which I never thought)

but unfortunately it´s in a really bad condition.

I have started to go thru the electronics and they seem to be up to spec with just some caps and resistors replacements

but the transport needs some serious overhauling.

The Reel idler seems to have taken some beating and I assume the shaft is bend!

So I need to found some one who can rebuild that motor and probably the Capstan motor also.

Anyone who can point to one preferable here in Europe but anywhere I the world will do.

but unfortunately it´s in a really bad condition.

I have started to go thru the electronics and they seem to be up to spec with just some caps and resistors replacements

but the transport needs some serious overhauling.

The Reel idler seems to have taken some beating and I assume the shaft is bend!

So I need to found some one who can rebuild that motor and probably the Capstan motor also.

Anyone who can point to one preferable here in Europe but anywhere I the world will do.

Starting an MR-70 rebuild/upgrade

I, too, am starting the process of restoring/upgrading a couple of MR-70 decks. One is back from Japan where it spent many years in a cave, and it's not very pretty. It is also 50 Hz so the capstan drive motor will not be used here in the USA. It came with some extra parts and reel motors scavenged from a second MR-70 that was left in the cave.

My plans for these decks are to replace the rubber tire capstan drive system with a custom-made servo direct drive capstan motor. The motor will have an alumina ceramic capstan shaft (like the MCI servo motors) which is non-magnetic to avoid conducting motor magnetism to the rolling tape. The alumina is also harder than the original shafts, so it won't shine up from tape contact. ABEC 7 bearings, a slottless (zero-cogging) brushless DC motor, a 5000 line optical encoder, and the original capstan flywheel reworked to clamp onto the shaft instead of being pinned will complete the assembly along with a modern digital motor drive. The motor must be custom made in order to fit into the deck plate casting in the same way as the original capstan bearing holder. I understand that Tom B. adapted a servo motor to his 300 deck. Maybe I can learn about his approach before I pull the trigger on my own design. I don't want to re-invent the wheel where I don't have to.

Another area under development is a replacement low THD, low noise master bias oscillator and a retrofitted solid-state bias amplifier for the electronics, since I understand that the original circuits cannot properly erase or bias modern tape formulations. I plan to fix the ground loop in the electronics, and if that doesn't bring the hum down to inaudible, then I might remote the power transformer and chokes to a box on the floor. Voltage regulation for at least the 12.6V heater supply is also in the works. I'm not sure about the 6.3V ac heaters yet.

We plan to use these decks to make records again, so we are hoping to get the lowest wow and flutter possible as well as improve on the noise floor without changing the magical sound of the nuvistor circuitry.

I am hoping those in this group with MR-70 experience might be able to lend guidance and suggestions along the way.

Thanks,

Steve Hogan

I, too, am starting the process of restoring/upgrading a couple of MR-70 decks. One is back from Japan where it spent many years in a cave, and it's not very pretty. It is also 50 Hz so the capstan drive motor will not be used here in the USA. It came with some extra parts and reel motors scavenged from a second MR-70 that was left in the cave.

My plans for these decks are to replace the rubber tire capstan drive system with a custom-made servo direct drive capstan motor. The motor will have an alumina ceramic capstan shaft (like the MCI servo motors) which is non-magnetic to avoid conducting motor magnetism to the rolling tape. The alumina is also harder than the original shafts, so it won't shine up from tape contact. ABEC 7 bearings, a slottless (zero-cogging) brushless DC motor, a 5000 line optical encoder, and the original capstan flywheel reworked to clamp onto the shaft instead of being pinned will complete the assembly along with a modern digital motor drive. The motor must be custom made in order to fit into the deck plate casting in the same way as the original capstan bearing holder. I understand that Tom B. adapted a servo motor to his 300 deck. Maybe I can learn about his approach before I pull the trigger on my own design. I don't want to re-invent the wheel where I don't have to.

Another area under development is a replacement low THD, low noise master bias oscillator and a retrofitted solid-state bias amplifier for the electronics, since I understand that the original circuits cannot properly erase or bias modern tape formulations. I plan to fix the ground loop in the electronics, and if that doesn't bring the hum down to inaudible, then I might remote the power transformer and chokes to a box on the floor. Voltage regulation for at least the 12.6V heater supply is also in the works. I'm not sure about the 6.3V ac heaters yet.

We plan to use these decks to make records again, so we are hoping to get the lowest wow and flutter possible as well as improve on the noise floor without changing the magical sound of the nuvistor circuitry.

I am hoping those in this group with MR-70 experience might be able to lend guidance and suggestions along the way.

Thanks,

Steve Hogan

Last edited:

Sounds like an ambitious project, more so as you're starting with one that's 'not very pretty'. The capstan drive system on the MR70 is only one of the challenges faced when working on these machines, but when it's in good order, it's fine.

See my post #99 in this thread: http://www.whatsbestforum.com/showthread.php?12554-Reference-tapemachine/page10

Tom

See my post #99 in this thread: http://www.whatsbestforum.com/showthread.php?12554-Reference-tapemachine/page10

Tom

Thanks for your encouragement.

I understand that you adapted a 4 speed servo capstan to your 300 deck. Can you share the details of that?

Also one of the electronics units I have here is missing parts, so I am hoping to find at least one additional electronics unit, maybe 2. It looks like there are more MR-70 decks on this forum than anywhere else in the world. Perhaps someone already has a parts electronics unit that I could use to complete mine.

Steve

I understand that you adapted a 4 speed servo capstan to your 300 deck. Can you share the details of that?

Also one of the electronics units I have here is missing parts, so I am hoping to find at least one additional electronics unit, maybe 2. It looks like there are more MR-70 decks on this forum than anywhere else in the world. Perhaps someone already has a parts electronics unit that I could use to complete mine.

Steve

For the 300 transports I used servo motors/controllers out of a 440B. IIRC it took around 40 hours to disassemble the transport and machine the deckplate/banjo casting, and perhaps another ten hours to figure out the electrical aspect, mostly centered on having the transport switch the speed pairs in the controller. Did two machines like that. Once you got past the necessary machining, the motor basically just bolted up to the transport deckplate (which is how the conversion kit works on the 440). It's four-speed, but you can only choose two speed pairs at a time and have to change jumpers to access the others. It does however work quite well and eliminates the problems with the 300 capstan drive.

The stock MR70 capstan drive improved upon the 300 and to me is easier to get more consistent performance out of, as long as the motor bearings are OK and the rubber tire is within specs. The 300 capstan drive can be painful to work on.

Tom

The stock MR70 capstan drive improved upon the 300 and to me is easier to get more consistent performance out of, as long as the motor bearings are OK and the rubber tire is within specs. The 300 capstan drive can be painful to work on.

Tom

I've done my best to convince Roger to let me buy one of his 1/4" change parts for my 1/2" 3 track MR-70 but hadn't been successful.

Hi Tom:

I used to talk to Roger quite often but lately he had gone silent. Hoping he is too buy playing tapes, he has no time to call.

It would be nice, if you can come up with 1/4" change parts someday.

Thanks,

Ki

I used to talk to Roger quite often but lately he had gone silent. Hoping he is too buy playing tapes, he has no time to call.

It would be nice, if you can come up with 1/4" change parts someday.

Thanks,

Ki

Similar threads

- Replies

- 10

- Views

- 890

- Replies

- 16

- Views

- 3K

- Replies

- 1

- Views

- 269

- Replies

- 6

- Views

- 404

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |