I've had variations on a recurring dream, since my late teen years.

In it, I'm wandering through an enormously large, bustling hi-fi store. It's filled with countless systems, set up side by side down the very wide aisles, each of varying expense and quality. I'm intrigued by everything but there are no familiar brands, and I'm not shopping for anything in particular. Each time I have the dream, I'm ultimately led by a salesman to an absolutely beautiful and utterly novel speaker of some kind, (one that I somehow am sure I cannot afford) and, I am wholly captivated by how it works and sounds. The designs don't often make sense, they have been countless over the years, and I fully remember only a handful. One that I've dreamt of for decades is omni-directional, and largely made of piano wire. It's much like an MBL Radialstrahler, but made from all 88 piano strings each having its own magnetic assembly. Another I often see is a pyramid several feet tall sitting on a stone base, with a flexible surround material joining its four sides. Each of the sides is made of a pearlescent lightweight material and acts as a transducer, as though the cabinet and driver are one and the same.

I wake from these dreams with a feeling of inspiration, having no idea how I'd ever make or experience something like what I've seen. My first sketches from these dreams are in an old notebook of mine from college, when I was 17 years old.

With that in mind, the idea of combining factory-made parts into a whole wasn't the least bit interesting to me. What was interesting to me was an attempt to actualize these dream experiences in some manner - to design and construct a complete loudspeaker by hand, and somehow introduce the novel magic into my designs that I'd felt inspired by in those experiences. I prepared by spending a week or so learning the basics of how an electrodynamic driver works. And then I set out to make my own, starting at the bottom of the object, with the magnet.

I soon discovered that in the absence of a professional facility and training, producing strong permanent magnets is potentially pretty dangerous. Compelling electrons to spin in persistent alignment requires a vast amount of electricity - more than enough current to tempt serious injury, or worse. I was willing to take on that risk, but my wife understandably vetoed such a proposal.

I had never heard of a field coil, but soon after found a forum thread about them. In it, a brilliant guy in Japan had constructed a driver and was using an electromagnet for it, that he had designed. His effort spanned dozens of pages, and included the musings of many gifted individuals, some in the audio industry, who had shared whatever they knew of the topic. I did a little digging, and discovered that not only were electromagnets a viable option, they represented some of the finest loudspeaker drivers in the world. I read the entire thread several times over, with many and often lengthy stops along the way to do research when I didn't understand the discussion.

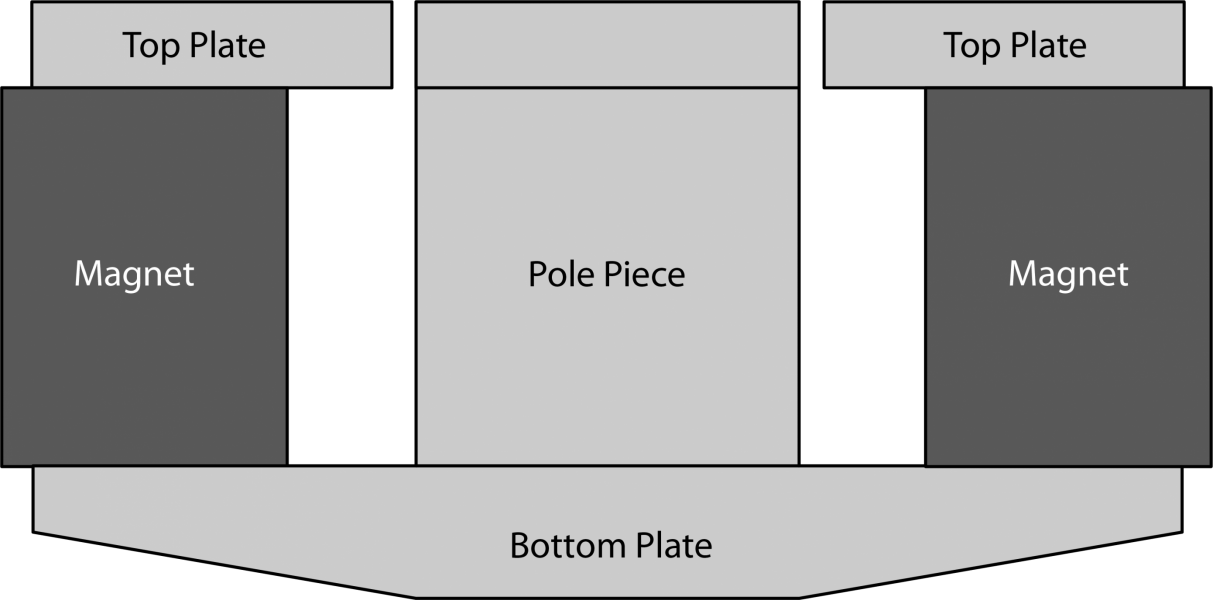

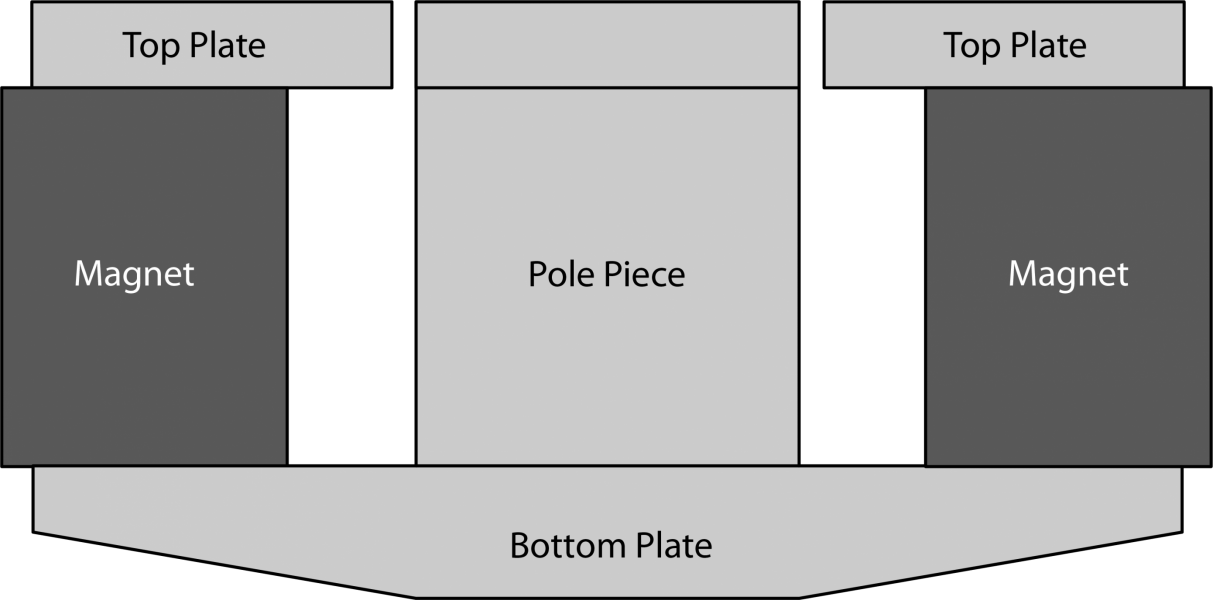

A few simple diagrams might be useful at this point. Permanent magnets come in endless variations and hybrids, however for the sake of simplicity many are open or closed circuits. An open circuit is the most common, often seen with ferrite magnets. In cross-section, it looks like this:

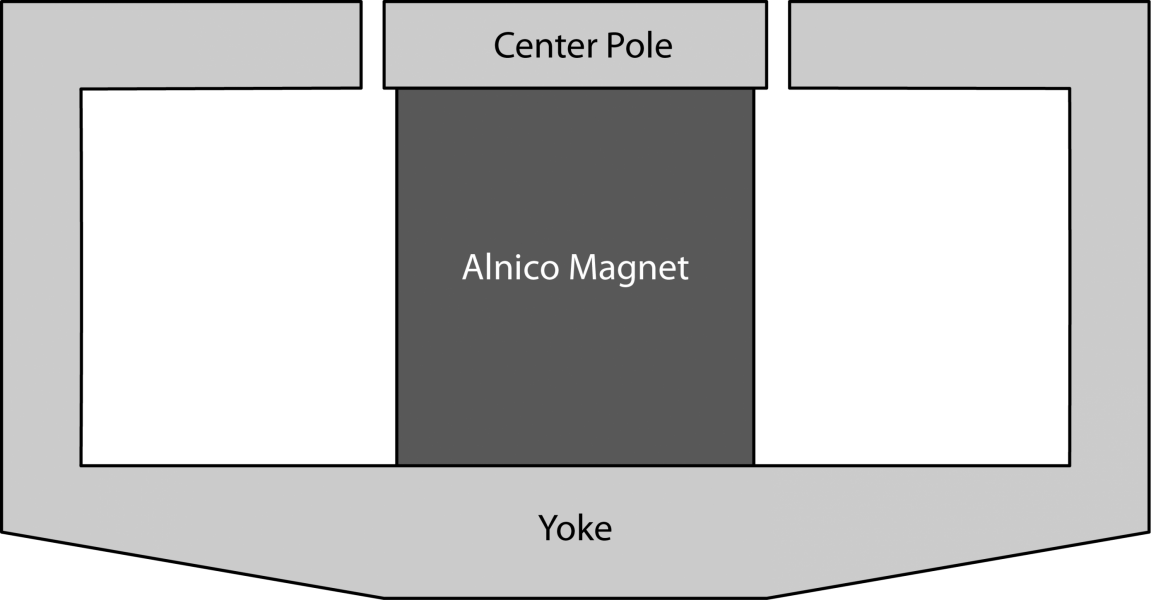

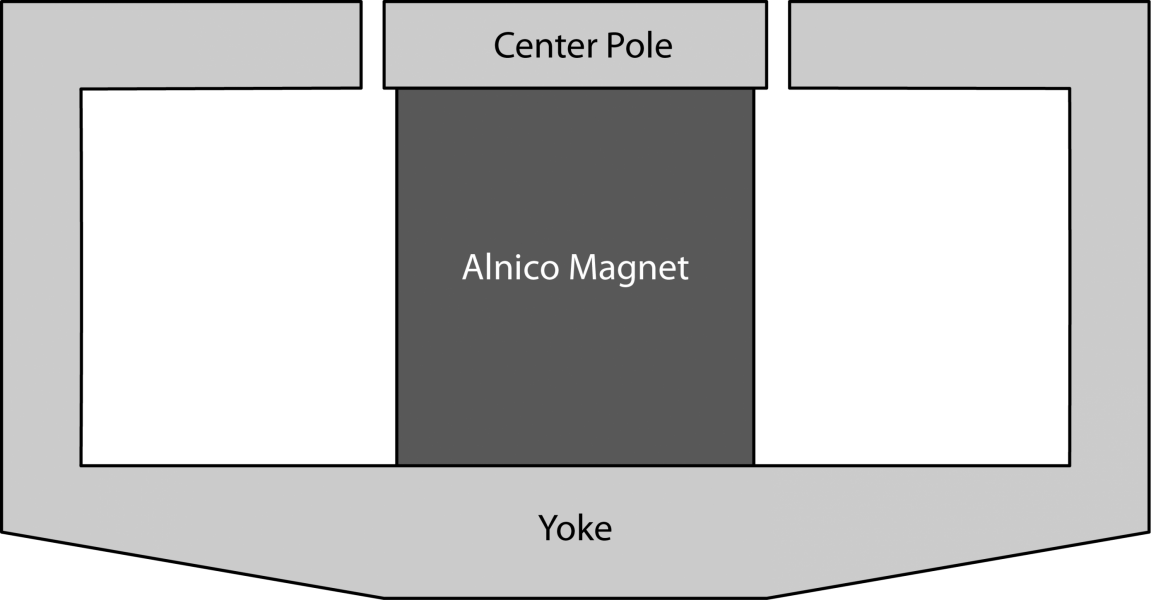

A closed circuit is less common. It is often seen with Alnico magnets, and looks something like this:

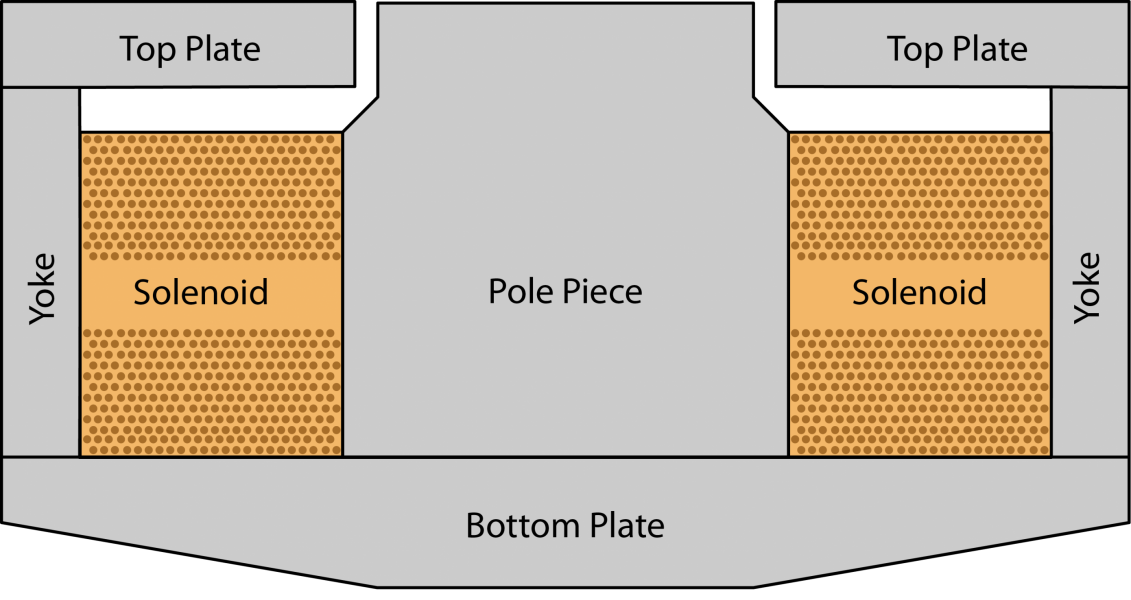

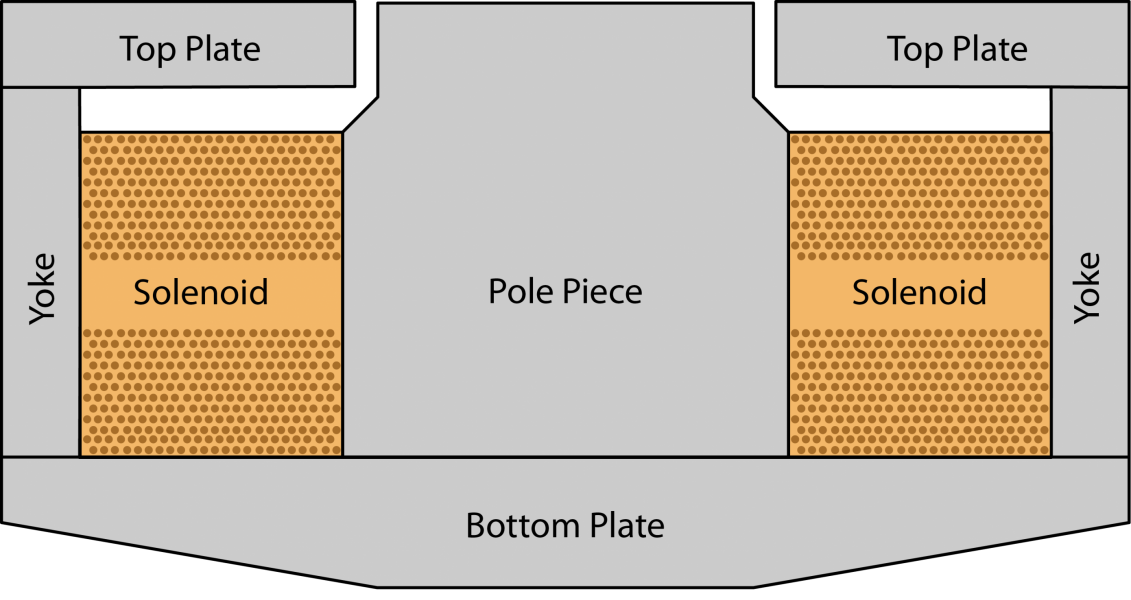

A field coil magnet is the least common. Many of us may recall from grade school that with nothing more than a battery, copper wire and an ordinary nail, anyone could make a magnet. A field coil is really no different. It's just much bigger, and it takes some skill and patience to make a truly excellent nail. Here's a cross section of what a field coil looks like:

In these diagrams, the voice coil sits in the gaps you see between the pole piece and the top plate. As alternating current signal passes through its wire, the resulting voice coil magnetic field interacts with that of the motor. It causes the voice coil and cones attached to it to oscillate, and that produces sound.

An unanticipated advantage to choosing a field coil architecture was, hilariously in retrospect, that it was easier. The best full range drivers implemented daunting tolerances in the gap, no more than the thickness of a dollar bill on either side of the voice coil. To manually achieve that tolerance in the presence of a constant magnetic field is a challenge. The freedom to simply turn the magnet off was for that reason, pretty useful.

Another advantage was that adjusting current to the field coil changes driver performance characteristics, known as Thiele/Small parameters. The more important of them in this context is called Qts, which is higher with low current, and lower with higher current to the field coil. That value indicates suitability for different implementations. The freedom to alter it with little or no effort gave me flexibility, to choose whatever kind of enclosures I liked, and to defer that decision for now.

A few of my basic design principles were these:

I set out to wind my first solenoids, using a simple wooden assembly and strong epoxy between each layer. This was my first try:

I know what you're thinking. It looks a little too handmade. I thought so too.

I went back to the drawing board, worked on my process for removing the coil from the bobbin, and tried again. That effort turned out like this:

Much better. 1475 turns, 19 layers, about 8 Ohms. Although, even with the help of a winding jig my wrists were sore for a week after winding that first pair.

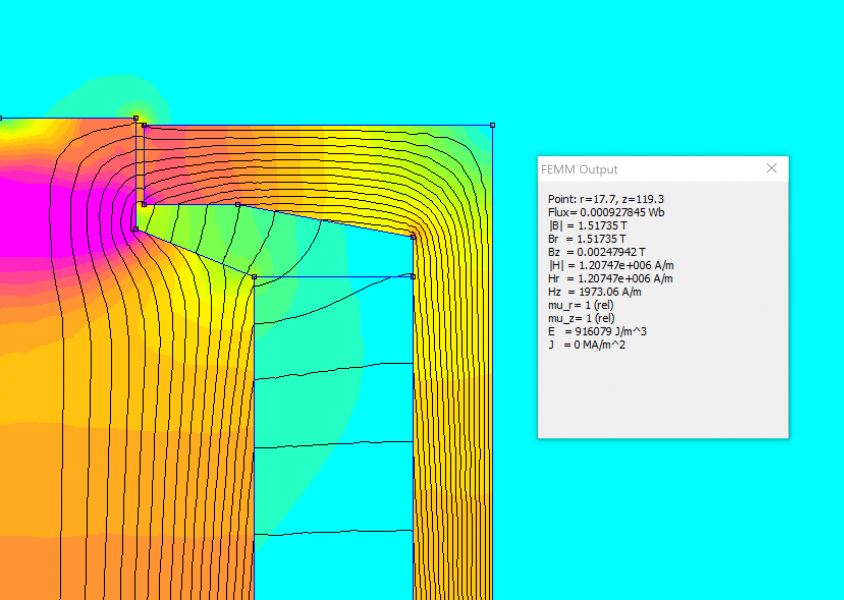

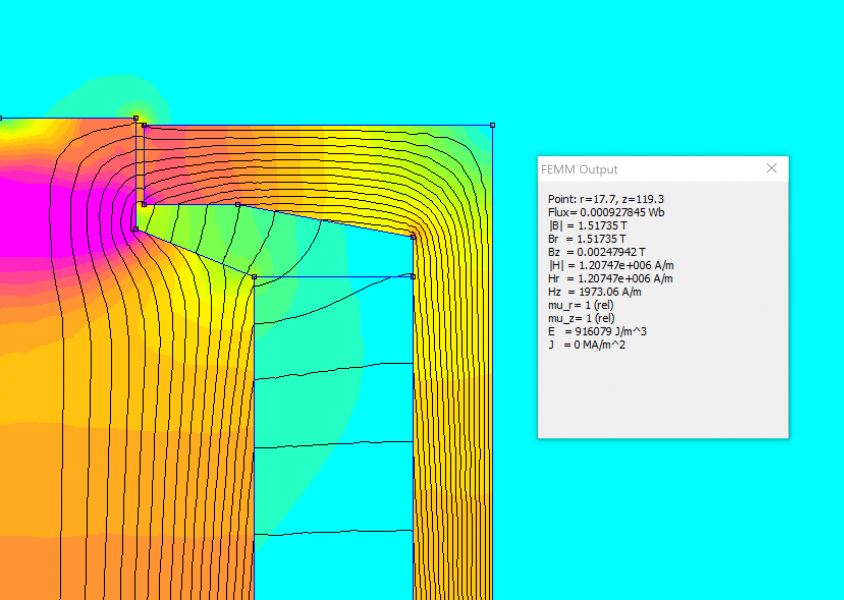

Represented as an axisymmetric problem in Finite Element Method Magnetics (FEMM), that motor performed like this:

About 1.5 Tesla in the gap, with a nice, uniform flux density.

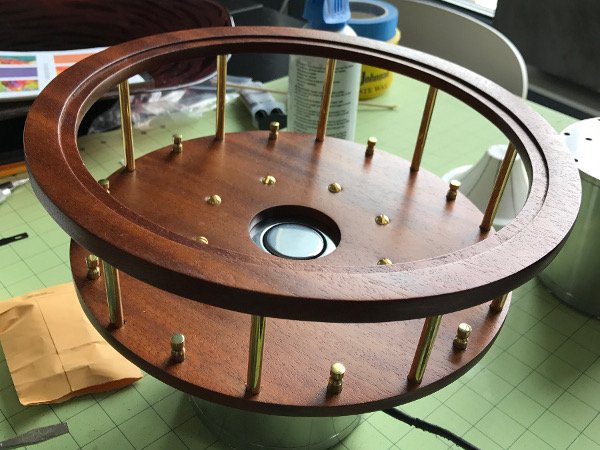

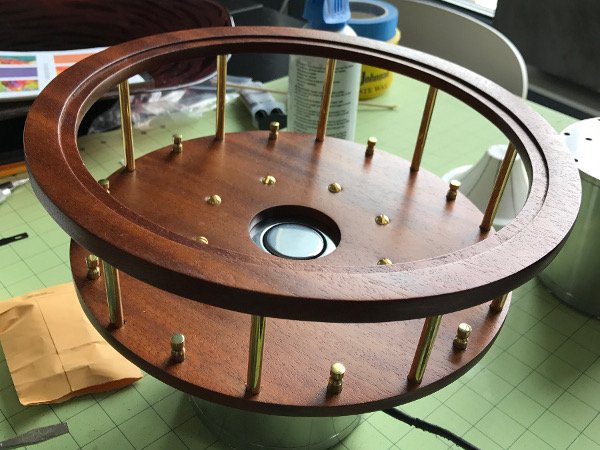

Because I knew I'd never trust the driver frame to hold the 20+ pound weight of the motor, I initially imagined the frame as something of a wooden instrument that may add a pleasing tonal character to the sound of the driver. That looked like this:

Obvious intuitions led me to first try silk threads as a spider suspension. I thought the footprint of the silk should be wide; imagine the vertical energy needed to move a lattice of a typical spider diameter. Then, imagine what might be needed for the same degree of movement in a lattice twice as wide, or even wider. My guess was that it should be significantly more sensitive. That looked like this:

The surrounds were lambskin, formed on a hydrocal mold:

The cones and voice coil formers were a combination of washi and kinwashi papers, also wet-formed on these first molds. There were dozens of early versions that were made and discarded, however the first working prototype included a washi former and whizzer, paired with a kinwashi main cone.

This next one is a real piece of history for me - it's the first time I ever heard any driver I've ever made play music. It's the finished pair from the images you see above, recorded one fine evening on my phone:

https://songeraudio.com/media/drivers_v1.html

While it may not translate in the video, they really did sound amazing... at least, certainly to me. Many text messages, some of them in all caps, were sent to friends and family that night.

Encouraged by the forward leap of progress, the next day I turned back to the internet. I needed to discover how it was possible that a driver made by a relative novice sounded as coherent, detailed and palpable as anything I had ever heard in my life - even when playing in free air, through mid-fi gear, on a carpet. I picked up a free copy of Fusion 360, taught myself some CAD/CAM design basics, and set to work feverishly and tirelessly designing a much improved motor structure. When I felt the design was finally good enough, I sunk most of my annual bonus that year into milling several sets of the new motor steel.

And that's where I'll stop, for now. Next up, some measurements of and a brief autopsy of the first prototype. From there I'll talk about the early beginnings of what has now become the current 10" field coil driver, which led me to eventually quit my day job and pursue audio full-time. Cheers, all.

In it, I'm wandering through an enormously large, bustling hi-fi store. It's filled with countless systems, set up side by side down the very wide aisles, each of varying expense and quality. I'm intrigued by everything but there are no familiar brands, and I'm not shopping for anything in particular. Each time I have the dream, I'm ultimately led by a salesman to an absolutely beautiful and utterly novel speaker of some kind, (one that I somehow am sure I cannot afford) and, I am wholly captivated by how it works and sounds. The designs don't often make sense, they have been countless over the years, and I fully remember only a handful. One that I've dreamt of for decades is omni-directional, and largely made of piano wire. It's much like an MBL Radialstrahler, but made from all 88 piano strings each having its own magnetic assembly. Another I often see is a pyramid several feet tall sitting on a stone base, with a flexible surround material joining its four sides. Each of the sides is made of a pearlescent lightweight material and acts as a transducer, as though the cabinet and driver are one and the same.

I wake from these dreams with a feeling of inspiration, having no idea how I'd ever make or experience something like what I've seen. My first sketches from these dreams are in an old notebook of mine from college, when I was 17 years old.

With that in mind, the idea of combining factory-made parts into a whole wasn't the least bit interesting to me. What was interesting to me was an attempt to actualize these dream experiences in some manner - to design and construct a complete loudspeaker by hand, and somehow introduce the novel magic into my designs that I'd felt inspired by in those experiences. I prepared by spending a week or so learning the basics of how an electrodynamic driver works. And then I set out to make my own, starting at the bottom of the object, with the magnet.

I soon discovered that in the absence of a professional facility and training, producing strong permanent magnets is potentially pretty dangerous. Compelling electrons to spin in persistent alignment requires a vast amount of electricity - more than enough current to tempt serious injury, or worse. I was willing to take on that risk, but my wife understandably vetoed such a proposal.

I had never heard of a field coil, but soon after found a forum thread about them. In it, a brilliant guy in Japan had constructed a driver and was using an electromagnet for it, that he had designed. His effort spanned dozens of pages, and included the musings of many gifted individuals, some in the audio industry, who had shared whatever they knew of the topic. I did a little digging, and discovered that not only were electromagnets a viable option, they represented some of the finest loudspeaker drivers in the world. I read the entire thread several times over, with many and often lengthy stops along the way to do research when I didn't understand the discussion.

A few simple diagrams might be useful at this point. Permanent magnets come in endless variations and hybrids, however for the sake of simplicity many are open or closed circuits. An open circuit is the most common, often seen with ferrite magnets. In cross-section, it looks like this:

A closed circuit is less common. It is often seen with Alnico magnets, and looks something like this:

A field coil magnet is the least common. Many of us may recall from grade school that with nothing more than a battery, copper wire and an ordinary nail, anyone could make a magnet. A field coil is really no different. It's just much bigger, and it takes some skill and patience to make a truly excellent nail. Here's a cross section of what a field coil looks like:

In these diagrams, the voice coil sits in the gaps you see between the pole piece and the top plate. As alternating current signal passes through its wire, the resulting voice coil magnetic field interacts with that of the motor. It causes the voice coil and cones attached to it to oscillate, and that produces sound.

An unanticipated advantage to choosing a field coil architecture was, hilariously in retrospect, that it was easier. The best full range drivers implemented daunting tolerances in the gap, no more than the thickness of a dollar bill on either side of the voice coil. To manually achieve that tolerance in the presence of a constant magnetic field is a challenge. The freedom to simply turn the magnet off was for that reason, pretty useful.

Another advantage was that adjusting current to the field coil changes driver performance characteristics, known as Thiele/Small parameters. The more important of them in this context is called Qts, which is higher with low current, and lower with higher current to the field coil. That value indicates suitability for different implementations. The freedom to alter it with little or no effort gave me flexibility, to choose whatever kind of enclosures I liked, and to defer that decision for now.

A few of my basic design principles were these:

- the motor should perform well on 12VDC

- the motor must not overheat, and must be as strong as possible

- the moving mass must be as light and stiff as possible

- the suspension must be as soft as possible

- the driver response must be truly full range

- if possible, innovate upon spider designs

I set out to wind my first solenoids, using a simple wooden assembly and strong epoxy between each layer. This was my first try:

I know what you're thinking. It looks a little too handmade. I thought so too.

I went back to the drawing board, worked on my process for removing the coil from the bobbin, and tried again. That effort turned out like this:

Much better. 1475 turns, 19 layers, about 8 Ohms. Although, even with the help of a winding jig my wrists were sore for a week after winding that first pair.

Represented as an axisymmetric problem in Finite Element Method Magnetics (FEMM), that motor performed like this:

About 1.5 Tesla in the gap, with a nice, uniform flux density.

Because I knew I'd never trust the driver frame to hold the 20+ pound weight of the motor, I initially imagined the frame as something of a wooden instrument that may add a pleasing tonal character to the sound of the driver. That looked like this:

Obvious intuitions led me to first try silk threads as a spider suspension. I thought the footprint of the silk should be wide; imagine the vertical energy needed to move a lattice of a typical spider diameter. Then, imagine what might be needed for the same degree of movement in a lattice twice as wide, or even wider. My guess was that it should be significantly more sensitive. That looked like this:

The surrounds were lambskin, formed on a hydrocal mold:

The cones and voice coil formers were a combination of washi and kinwashi papers, also wet-formed on these first molds. There were dozens of early versions that were made and discarded, however the first working prototype included a washi former and whizzer, paired with a kinwashi main cone.

This next one is a real piece of history for me - it's the first time I ever heard any driver I've ever made play music. It's the finished pair from the images you see above, recorded one fine evening on my phone:

https://songeraudio.com/media/drivers_v1.html

While it may not translate in the video, they really did sound amazing... at least, certainly to me. Many text messages, some of them in all caps, were sent to friends and family that night.

Encouraged by the forward leap of progress, the next day I turned back to the internet. I needed to discover how it was possible that a driver made by a relative novice sounded as coherent, detailed and palpable as anything I had ever heard in my life - even when playing in free air, through mid-fi gear, on a carpet. I picked up a free copy of Fusion 360, taught myself some CAD/CAM design basics, and set to work feverishly and tirelessly designing a much improved motor structure. When I felt the design was finally good enough, I sunk most of my annual bonus that year into milling several sets of the new motor steel.

And that's where I'll stop, for now. Next up, some measurements of and a brief autopsy of the first prototype. From there I'll talk about the early beginnings of what has now become the current 10" field coil driver, which led me to eventually quit my day job and pursue audio full-time. Cheers, all.

Last edited: