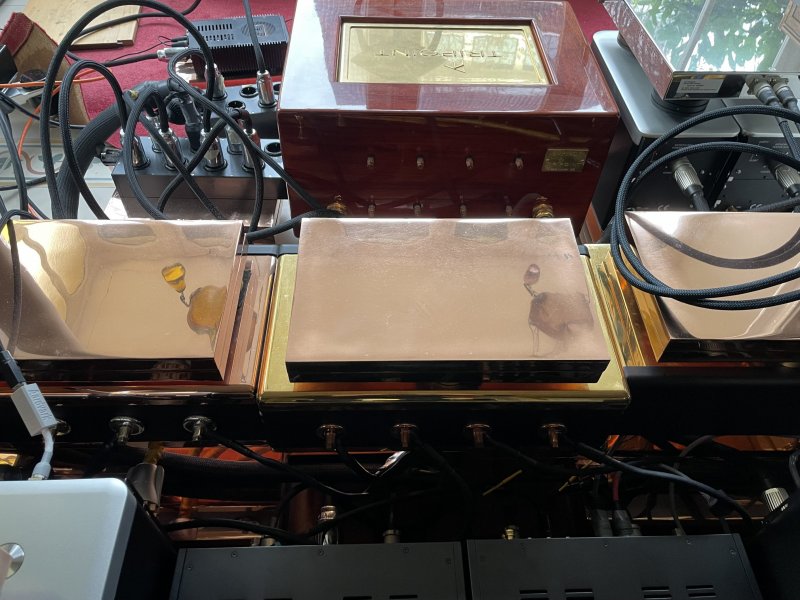

I can concur that mass loading makes a significant difference for the better. Mass loading my Wadax reference dac and server (the chassis of both these units are made out of aluminum) as well as my various Tripoint Audio NG ‘grounding’ stations. Will mass load my Kondo poweramps as well as soon as I have received more RevOpods. Place the latter on top of the audio components before adding pure, oxygen free and sanded (but apart from sanding untreated) copper slabs. Two slabs of each 2,5cm thickness are placed on top of each other in order to create mass. To give you an idea: on top of the Wadax reference server the two copper slabs weigh in total 50 kg. On the Wadax reference dac I am using larger copper slabs (because on top of these slabs I have placed my Zanden 2000p cd-transport). The weight of these two slabs is around 90kg.

Component Mass Loading and Dampening

- Thread starter Testy Troll

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good for you. All of my gear is seriously mass-loaded. I've nearly 1000 lbs. of controllled compressive force on my half-width Class D monoblock amps, roughly 650 lbs. on my DAC and nearly 350 lbs. on each of my rather small line conditioners. All via a custom racking system I designed. Makes all the difference in the world.I can concur that mass loading makes a significant difference for the better. Mass loading my Wadax reference dac and server (the chassis of both these units are made out of aluminum) as well as my various Tripoint Audio NG ‘grounding’ stations. Will mass load my Kondo poweramps as well as soon as I have received more RevOpods. Place the latter on top of the audio components before adding pure, oxygen free and sanded (but apart from sanding untreated) copper slabs. Two slabs of each 2,5cm thickness are placed on top of each other in order to create mass. To give you an idea: on top of the Wadax reference server the two copper slabs weigh in total 50 kg. On the Wadax reference dac I am using larger copper slabs (because on top of these slabs I have placed my Zanden 2000p cd-transport). The weight of these two slabs is around 90kg.

Rudolf, can you explain how exactly did you mass load your Tripoint’s? They are beautifully finished, extremely compact and weigh about 100kg each and still benefit from additional mass load?I can concur that mass loading makes a significant difference for the better. Mass loading my Wadax reference dac and server (the chassis of both these units are made out of aluminum) as well as my various Tripoint Audio NG ‘grounding’ stations.

Hi Marcus, I started mass loading after talking with Miguel about this topic. He researched this phenomenon in the past and has as a consequence very outspoken ideas about it. The material that is being used for mass loading is according to him of great importance. That is the reason why I have opted for pure, oxygen free and untreated copper, a quite expensive option of course. Using a different material for mass loading than the material the chassis of the various audio components is made of - aluminum (Wadax reference server and dac) and (mostly) brass (the two Tripoint Elite NG ‘grounding’ units) - is according to Miguel also important. That said I could clearly hear benefits when I started mass loading the Emperor NG - which is (mostly) made out of pure copper - as well. First I tried one copper platform on the various audio components and after serious listening I added a second one. More mass by adding a second copper slab resulted clearly in greater musical benefits.

First I placed three RevOpod footers on top of the various Tripoint Audio NG’s. Secondly I placed (first) one copper slab of 2.5cm thickness on these three footers. As mentioned before after some serious listening I added a second copper slab of 2.5cm thickness on top of the first one.

Hope this gives you a good idea.

First I placed three RevOpod footers on top of the various Tripoint Audio NG’s. Secondly I placed (first) one copper slab of 2.5cm thickness on these three footers. As mentioned before after some serious listening I added a second copper slab of 2.5cm thickness on top of the first one.

Hope this gives you a good idea.

Last edited:

Thanks for the reply stehno. While any non magnetic weight will help, I’ve had particularly good results using slate plates after trying various types of timber. It could be that it’s the slates added density that makes the difference and the fact that it is a material with inherent layers. I have used slate for plinths successfully, in a adapted Barry Diament configuration using first 3 cups and ball devices by Ingress Engineering set up on 30mm slate plinths which in turn are supported by under inflated inner tubes from kids bicycles.

I tried selling this configuration on my ebay site, without any interest, so I removed it. I may try again with the addition of the slate mass load damping blocks with machined hand holds and a layer of cork on the bottom. Anyhow, it all definitely works to produce a more open, well defined and musical sound. Any further thoughts or questions let us know.

I tried selling this configuration on my ebay site, without any interest, so I removed it. I may try again with the addition of the slate mass load damping blocks with machined hand holds and a layer of cork on the bottom. Anyhow, it all definitely works to produce a more open, well defined and musical sound. Any further thoughts or questions let us know.

I suppose copper might be next level? I presume you have tried other materials, your experiences of that would be interesting to read.Per request I attach a photo of the three Tripoint Audio NG’groubding’ units being mass loaded with two copper slabs on top of each other.

I am sorry but I have not tried other materials than copper for mass loading. I made this ‘mass loading step’ in close cooperation with Miguel of Tripoint Audio and he is very much in favor of copper.I suppose copper might be next level? I presume you have tried other materials, your experiences of that would be interesting to read.

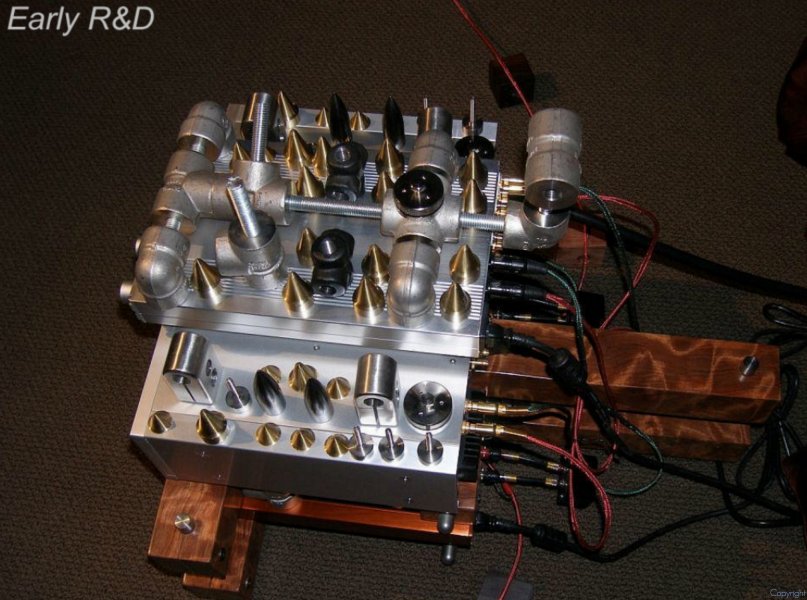

I started dabbling with racking system designs in 2001 and then started dabbling with mass-loading in 2005. This picture was taken in 2007.

In late 2006, something prompted me to go a different route. I started with a clean slate and dug out all the spare metal parts I had lying around the shop. I started by installing 3 little metal parts like 3 of the larger brass points in the picture above and just placed them on top of Esoteric unit and let it sit. A few days later, I just so happened to hear a little but still distinct performance improvement. So I placed 3 more small metal parts on the top plate and waited. Sure enough, a few days later another little but still distinct performance gain.

So I made it a habit of doing this until I completely saturated the top plate's real estate with various metal parts. After the 4th or 5th improvement I noticed each little install of 3 parts took roughly 53 hours or 2 days and 5 hours to seemingly fully settle-in.

Considering my 3 little installs/placements amounted to 20 or 30 iterations, that 53 hours of settling-in time was consistent throughout. Once the top plate's real estate was completed saturated I had to advance to other strategies since my components seemigly loved more weight.

Great posts. I've been advocating mass loading components for many years. I use jeweler's blocks and stand - alone door stops to good effect. I would agree that the amount of weight and type likely play a role in the benefit or lack thereof as different materials of different size and thickness will also resonate adding their own signature although this might be a worthwhile tradeoff versus no extra weight / mass. Also, I have seen no tech paper(s) that compare different materials on different components; that would be quite interesting as my instinct tells me that, as commonly employed with turntables, the right combination of multiple materials of different weight, quantity and thickness likely yield bigger sonics benefits.

Big fan myself. Just completed placing Artesania damping plates one at a time on each of the back shelves of the XLF modules. Big improvement...definitely takes around 3 days to feel the full effect though its mainly there right up front. Not sure why. Each XLF has around 35kg or 77 pounds on the back between the crossover, the shelves and the back main unit. With the Velodyne, the speakers probably are 65% of all the mass damping (of the 260+kg of weight across all the components)

ALL of the components across the entire system have isolation underneath and a different level/kind of damping on top. Robert Koch even 'signed off' on the work when he kindly came over for a visit and saw his amps in my 'isolation sandwich' with isolation underneath and damping on top.

ALL of the components across the entire system have isolation underneath and a different level/kind of damping on top. Robert Koch even 'signed off' on the work when he kindly came over for a visit and saw his amps in my 'isolation sandwich' with isolation underneath and damping on top.

it's possible that the extra weight on the speakers adds increased stiffness and helps absorb movement while driving up the frequency of internal resonances away from audible frequencies.Big fan myself. Just completed placing Artesania damping plates one at a time on each of the back shelves of the XLF modules. Big improvement...definitely takes around 3 days to feel the full effect though its mainly there right up front. Not sure why. Each XLF has around 35kg or 77 pounds on the back between the crossover, the shelves and the back main unit. With the Velodyne, the speakers probably are 65% of all the mass damping (of the 260+kg of weight across all the components)

ALL of the components across the entire system have isolation underneath and a different level/kind of damping on top. Robert Koch even 'signed off' on the work when he kindly came over for a visit and saw his amps in my 'isolation sandwich' with isolation underneath and damping on top.

Thank you. I will say that because the XLF upper modules are all moveable (I do NOT touch those)...I realized that each is effectively resting on spikes that are on tracks embedded on its own inert shelf. And THAT inert non-moving shelf is what I have massed damped. And it works really really well. No change in tonal qualities, but significantly increased alacrity, clarity and ease.it's possible that the extra weight on the speakers adds increased stiffness and helps absorb movement while driving up the frequency of internal resonances away from audible frequencies.

My Aries Cerat components have heavy steel lids which are removable for access to tubes and biasing adjustments. But they ring like a bell. The solid steel ingots are about 50 lbs on each top. I also put contained layer tape on the inside surfaces. The weights have a much larger impact than the tape.

View attachment 123094

View attachment 123094

Last edited:

I’m curious. Do those endorsing mass-loading (and damping too) realize they’re actually confessing at least some allegiance to the resonant energy transfer aka coupling methodology (or at least to some principles thereof) rather than the isolation aka decoupling methodology that so many hold dear?

IOW, what could the concept of mass-loading and damping possibly have to do with the act of isolation?

IOW, what could the concept of mass-loading and damping possibly have to do with the act of isolation?

Last edited:

I’m curious. Do those endorsing mass-loading (and damping too) realize they’re actually confessing at least some allegiance to the resonant energy transfer aka coupling methodology (or at least to some principles thereof) rather than the isolation aka decoupling methodology that so many hold dear?

IOW, what could the concept of mass-loading and damping possibly have to do with the act of isolation?

I put the steel ingots on my A.Cerat gear based simply on my version of common sense. The AC gear is very heavy and solid, but the top steel plates which are designed to be easily removable to expose tubes, ring like a bad cymbol when tapped. I assume this does not translate well to ideal audio and Stravos of AC confirmed the sound is best with the tops completely removed. (He also said acrylic would be better than the steel, but is not practical give the size of the span.). I don't want to leave the tops off because I'm positive a mouse would eventually take of residence inside the preamp.

In any case, with the 50 lb steel weights, it now makes a nice solid "thunk" similar to the sound of the solid chassis sides albeit at a much lower frequency on top than the sides.

Are you saying this use of mass loading is at odds (or working contrary to isolation)? It's seems to me they can work in concert.

I admit I find much of the discussion and marketing claims around vibration mitigation to often be contradictory and confounding.

The Revopods which I use under the AC gear are described both as isolators and as damping devices which disband vibrations in all directions. They are based on pot bearing damping along the lines of what used on bridges.

They are certainly not based on coupling methodology.

Yes, it's not unusal to invoke mass-loading with the intention of damping a flimsy or poorly anchored top plate to prevent it from vibrating in sympathy with vibrations already captured. However, it's important to note that when mass-loading a top plate you're not just mass-loading/damping a top plate but you are actually mass-loading/damping the entire component chassis and quite possibly a few internals - if the chassis is torqued much.I put the steel ingots on my A.Cerat gear based simply on my version of common sense. The AC gear is very heavy and solid, but the top steel plates which are designed to be easily removable to expose tubes, ring like a bad cymbol when tapped. I assume this does not translate well to ideal audio and Stravos of AC confirmed the sound is best with the tops completely removed. (He also said acrylic would be better than the steel, but is not practical give the size of the span.). I don't want to leave the tops off because I'm positive a mouse would eventually take of residence inside the preamp.

Though it can provide some psychological comfort, I would caution against listening to the sound of tapping a chassis when dabbling with vibration mgmt as there usually isn't much if any sonic value associated with it. In fact, if the vibrations captured at the component are going to remain trapped at the component, I'd probably much prefer the chassis to resonate rather than the internals. As a side note, vibrating component chassis parts in and of themselves have no direct impact on the input signal's fidelity. Rather, it's what this unwanted mechanical energy does to the electronic internals that greatly compromises the input signal's fidelity.In any case, with the 50 lb steel weights, it now makes a nice solid "thunk" similar to the sound of the solid chassis sides albeit at a much lower frequency on top than the sides.

Yes, that is what I'm saying. We're talking opposing methodologies so in a sense mixing the two is like trying to develop a hybrid between light and dark, on and off, or hot and cold. IOW, by mixing the two methodologies you are creating a performance brick wall for each thereby preventing either one from being sufficiently executed to its natural completion. IOW, a lack of completion for either methodology will exist and at least with the coupling methodology will induce a very serious performance-limiting governor whenever it encounters a genuine decoupling section in the path. A methodology is only as good as its weakest link, right?Are you saying this use of mass loading is at odds (or working contrary to isolation)?

So when one is concerned about a top plate vibrating, we've already admitted that no matter what we think we've done to remedy a problem, somehow some way vibrations are still captured at the component and perhaps releasing its energy at an easily excitable location within - like a flimsy top plate. But when you mass-load / damp a top plate and potentially an entire component chassis in addition to you're otherwise attempting to somehow generally follow the isolation methodology, where are you hoping that energy trapped at the component will be released?

I've asked this several times before. What does an object become when it is sufficiently damped?

Sure, it can work and with some sonic benefit as many here claim. But any hope for real potential for sonics to soar are gone since when we hear any supposedly genuine improvement we're most likely to close the book on that chapter and move on to something else - rather than think it through any further.It's seems to me they can work in concert.

Understood. It's a huge club - probably the biggest club in high-end audio since perhaps 99.5% of all particpants will claim they are of the isolation camp.I admit I find much of the discussion and marketing claims around vibration mitigation to often be contradictory and confounding.

I've not seen the Revopods but I'll bet dollars-to-donuts based on the design, materials, executions, etc they're closer to the coupling methodology (though inferior) than to the decoupling methodology. Just as are many products supposedly belonging to the isolation methodology camp. Like I said, it's a huge club and it includes designers, mfg'ers, dealers, distributors, reviewers, enthusiasts, professionals, etc. Even the jargon used is inaccurate most times.The Revopods which I use under the AC gear are described both as isolators and as damping devices which disband vibrations in all directions. They are based on pot bearing damping along the lines of what used on bridges.

They are certainly not based on coupling methodology.

You've realized some coupling benefits with mass-loading / damping. If you really want to see what the coupling methodology is capable of, try following through on the coupling methodology. You've already started down the coupling path by mass-loading / damping. The next question is, what's really going on underneath between the component and shelf? Then evaluate the interface between the shelf and racking system, then the interface between the racking system (and speakers) and floor.

IOW, to maximize the performance potential of perhaps any methodology, one must see it through to completion.

Similar threads

- Replies

- 0

- Views

- 645

- Replies

- 15

- Views

- 1K

- Replies

- 1

- Views

- 1K

- Replies

- 3

- Views

- 702

- Replies

- 11

- Views

- 1K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |