Firstly I'm entirely new to this forum and greetings to everyone!

I stumbled upon this forum as I try to get more information on the Forsell Air Ref TT (the one w/o flywheel) and there are members here who have experience in the TT.

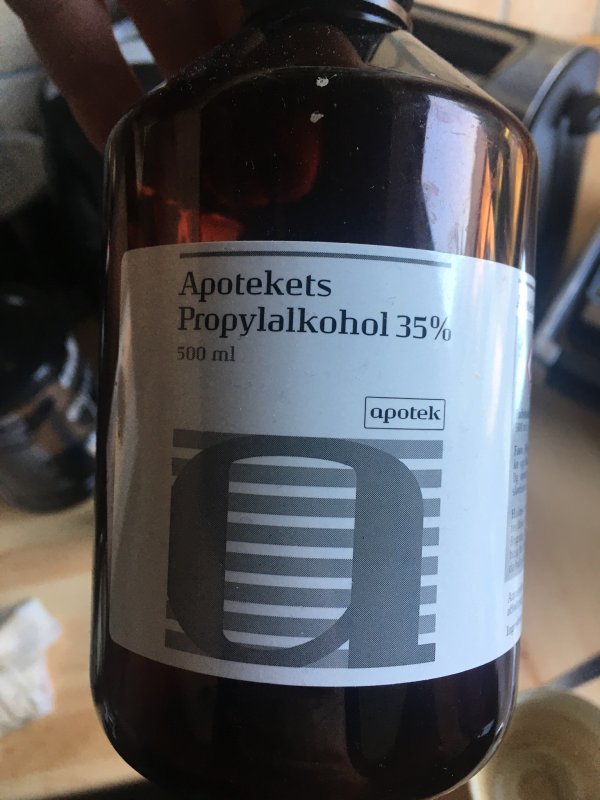

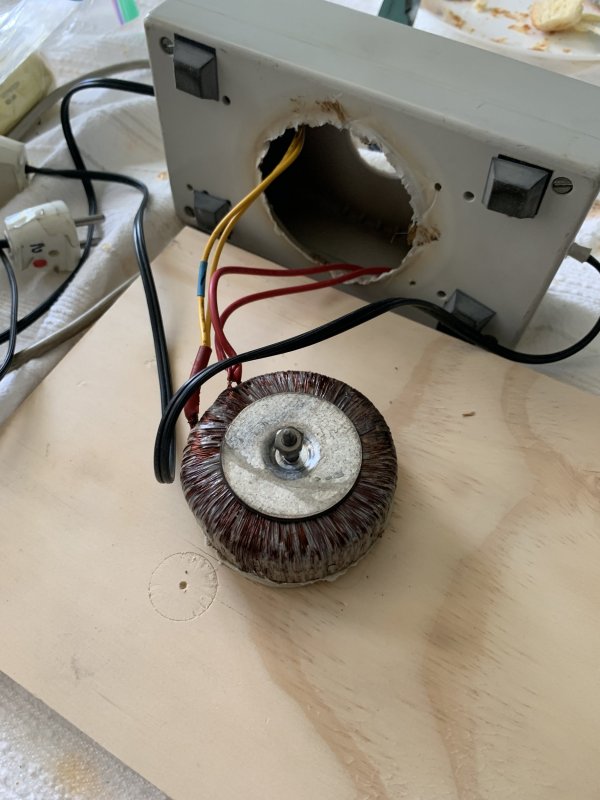

I have one that has not been used for over 10 years. I cleaned it up, change the plastic air tubes which have deteriorated and fired it up. I get lots of skips playing the record (i.e. the music keep repeating itself, "sounds like a broken record"). I checked the tonearm and I can feel the friction on the air bearing (with the pump on) which I remember was much smoother last time I used it. I suspect the air bearing had minute amount of oxidation or corrosion and has too much friction for the arm to glide though. The air seems to flow freely and I cleaned everything thoroughly.

Does anyone have any ideas what can be done about this? it will be a pity for such a great TT to go to waste but Forsell told me that they don't support the TT any more because of lack of parts.

I stumbled upon this forum as I try to get more information on the Forsell Air Ref TT (the one w/o flywheel) and there are members here who have experience in the TT.

I have one that has not been used for over 10 years. I cleaned it up, change the plastic air tubes which have deteriorated and fired it up. I get lots of skips playing the record (i.e. the music keep repeating itself, "sounds like a broken record"). I checked the tonearm and I can feel the friction on the air bearing (with the pump on) which I remember was much smoother last time I used it. I suspect the air bearing had minute amount of oxidation or corrosion and has too much friction for the arm to glide though. The air seems to flow freely and I cleaned everything thoroughly.

Does anyone have any ideas what can be done about this? it will be a pity for such a great TT to go to waste but Forsell told me that they don't support the TT any more because of lack of parts.