As with all of my non-loudspeaker products, I only get into something when I find that what is available commercially does not satisfy. I've had a stable of cartridges that I rotate because none of them totally satisfy. The Transfiguration Proteus D was my favorite overall, but unfortunately is no longer available.

However, the Sonic X4 is not just my design. It has a lot of my inputs and nudges in the direction I wanted it to go, but it also has the cumulative set of ideas, ideals and desires that my partners at Hyper wanted. And combined, the four of us have over 150 years of shared knowledge and experience in music reproduction (including recording and music making).

We showed various prototypes at all previous shows that we participated in, and the final prototype was showed at the Pacific Audiofest in Summer. At the recent Capital Audiofest, the first production unit (Serial No. #001) had a few of my friends awestruck at what it could retrieve from vinyl grooves.

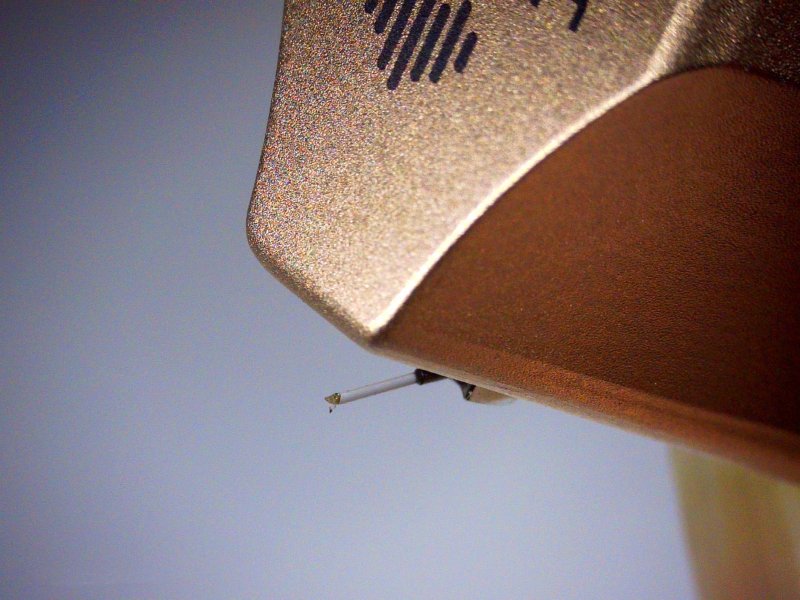

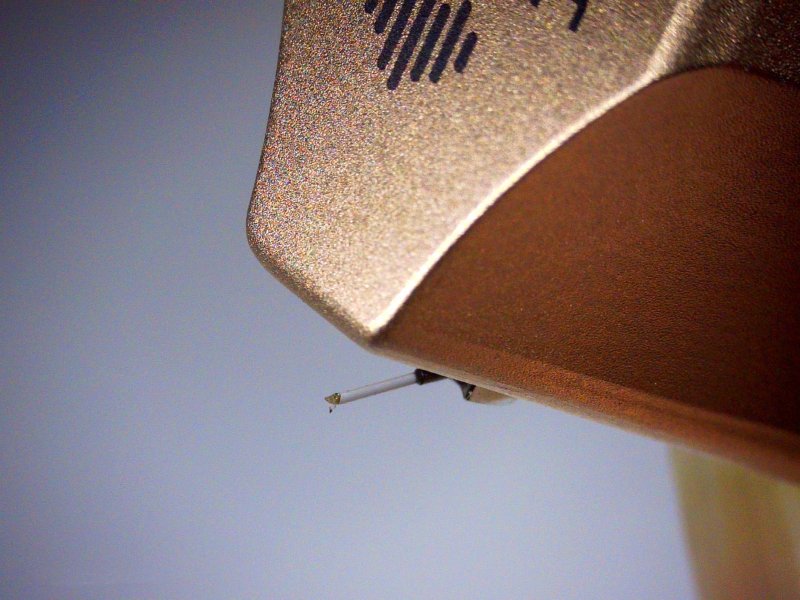

Making a phono cartridge for extreme performance, EVERYTHING matters. It was built by a renown Swiss cartridge maker to our extreme specifications. The Hyper Sonic X4 is a unique moving coil cartridge with a Multi-Layer Core. Combined with a new, stronger magnetic alloy shaped for better focus of magnetic flux, less coil-turns could be used for a given electrical output. (only 0.2mV output with 4 ohm impedance)

A stiff sapphire cantilever was chosen. This is inserted into a hardened titanium sleeve to transfer every micro-deflection generated by the micro-ridge stylus to the moving coil. This gives the Sonic X4 the ability to trace every minute detail of the grooves cut in the lacquer by the sharp cutter of the lathe. The generator is rigidly held in place relative to the interface to the tonearm with a titanium superstructure. The body is made of shot-peen surface hardened titanium. Three tungsten inserts are strategically placed to enhance the inertia stability of the cartridge and improve resonance damping.

Playing a reference lacquer cut by Bernie Grundman, and comparing to the 30ips master that he used to cut that lacquer, this is as good as it gets.

However, the Sonic X4 is not just my design. It has a lot of my inputs and nudges in the direction I wanted it to go, but it also has the cumulative set of ideas, ideals and desires that my partners at Hyper wanted. And combined, the four of us have over 150 years of shared knowledge and experience in music reproduction (including recording and music making).

We showed various prototypes at all previous shows that we participated in, and the final prototype was showed at the Pacific Audiofest in Summer. At the recent Capital Audiofest, the first production unit (Serial No. #001) had a few of my friends awestruck at what it could retrieve from vinyl grooves.

Making a phono cartridge for extreme performance, EVERYTHING matters. It was built by a renown Swiss cartridge maker to our extreme specifications. The Hyper Sonic X4 is a unique moving coil cartridge with a Multi-Layer Core. Combined with a new, stronger magnetic alloy shaped for better focus of magnetic flux, less coil-turns could be used for a given electrical output. (only 0.2mV output with 4 ohm impedance)

A stiff sapphire cantilever was chosen. This is inserted into a hardened titanium sleeve to transfer every micro-deflection generated by the micro-ridge stylus to the moving coil. This gives the Sonic X4 the ability to trace every minute detail of the grooves cut in the lacquer by the sharp cutter of the lathe. The generator is rigidly held in place relative to the interface to the tonearm with a titanium superstructure. The body is made of shot-peen surface hardened titanium. Three tungsten inserts are strategically placed to enhance the inertia stability of the cartridge and improve resonance damping.

Playing a reference lacquer cut by Bernie Grundman, and comparing to the 30ips master that he used to cut that lacquer, this is as good as it gets.