I pulled the shims from my cartridge and went direct to the head shell. It was pretty fast and easy to do. Took me about an hour. I looked at the needed spacers to go under the Wally Reference tool and set the SRA height for no shims between the cartridge and head shell. I then set the tracking weight, then the azimuth, then the zenith. Then dialed the weight in again. I am super happy with my vinyl performance. I don't know if I really hear anything different between the shim and direct to the head shell. I would assume to the head shell is a better contact to drain vibrations??? My mind says its all fantastic.

I was a little surprised how low I had to drop the arm to get to the correct SRA. I had to put tape on the tone arm lifter to get the height up a little and I had to put a shim under the tone arm cradle the arms rests in when not over the platter. Neither alterations should impact playback so all is well as far as I am concerned.

I still feel its a no brainer when it comes to using WAM services to analyze a cartridge. There is no way I would have my cartridge any where near optimum without it. I have had 2 experts at my house helping me setup cartridge in the past. Neither were anywhere near close to optimum as the report shows me. And my vinyl did not sound anywhere near as good as it does now.

Its kind of funny I have one friend with an AirTight Opus and he is nervous the cartridge will get lost or damaged in shipping, so he is happy to use it on a guess its correct. I think that is crazy. He spent so much on that cartridge. Why would you ever spend around $12K and probably never have the cart set up properly. I only know 3 members I feel could dial in a cartridge over some amount of time and get it right. I have no idea about the rest.

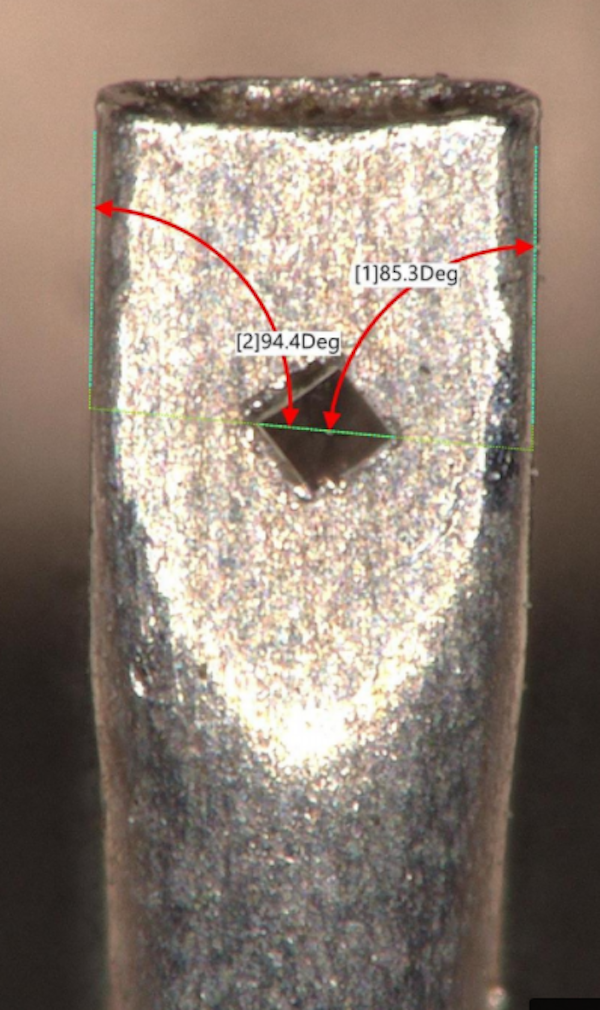

For whats its worth. A good part of my setup time is setting azimuth on my arm. I have a 114mm piece of straw I lay across the head shell. Every mm of change between left and right height is 1/2 degree in azimuth. I then have to twist a weight with no reference marks ( I did use some blue tape) on the spindle clock or counter clock to alter the azimuth. The straw would fall off all the time and it is a game of cat and mouse with the over shoot, under shoot when turning a single couter weight by hand. I ended up with 22mm on one side and 19 mm on the other. So 3mm total. That is close enough to correct for my azimuth being 1.6 degree out clockwise.