David, this does indeed seem to be the case. I spent some time today with the MINT Protractor investigating the effect on overhang resulting from small changes to arm height. I first measured the thickness of the glass MINT protractor. I then measured the thickness of the average LP in my collection. I compared these to my average arm height level per my measurement methods and set up the experiment.

MINT Protractor: 3.0mm

Ave. LP: 1.5mm

Ave. arm height: 17.25mm

I took the difference between the MINT and LP thickness of 1.5mm and added this to my arm height so that the surface of the MINT relative to the arm height (VTA and SRA) would mimic the condition when the stylus is on an average LP.

17.25mm + 1.5mm + 18.75mm.

I raised and set the arm height to this 18.75mm level. This is a true representation of the arm height when playing an average LP except that the stylus is now resting on the inscribed arc line on the MINT protractor rather than in the groove of the thinner LP. That arc line looks to be slightly wider than the 0.1mm thickness of a human hair.

I now adjusted the arm up and down by 1.5mm in each direction which is slightly more than I raise and lower the arm up or down when playing the various LPs of my collection. I wanted to see how these changes in arm height would affect the movement of the stylus tip relative to the inscribed arc line on the MINT protractor.

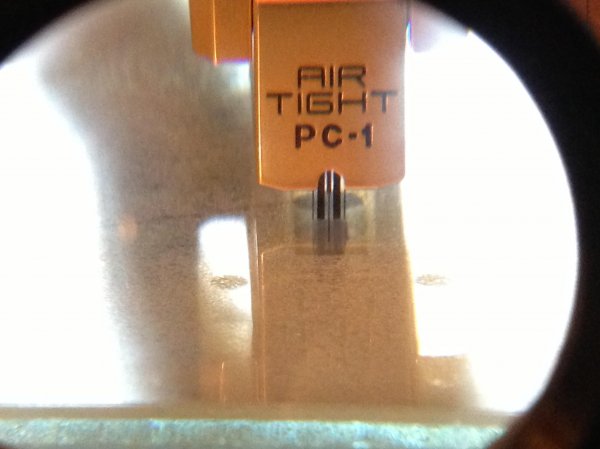

With the arm at 18.75mm, the stylus made contact with the center of the arc line throughout its entire length. This was not visible by my naked eye, so I used the 10X loupe supplied by MINT and a good lighting source to confirm.

I raised the arm by 1.5mm to 20.25mm and looked at the stylus through the loupe. It was extremely hard to see the exact amount of movement, but it looked like the stylus now rested on the inner edge of the arc line representing the outter most grooves of an LP. Toward the spindle, or inner groove of the LP, the stylus was on the line.

I then lowered the arm by 1.5mm to 17.25mm and again looked at the stylus through the loupe. Now it appeared to rest on the very outside edge of the arc line at the outer groove of the LP. Near the spindle, the stylus was again on the line.

So the only detectible movement in overhang was at the outer part of the arc and it was only visible through the 10X loupe and it only changed by roughly the thickness of the line or 0.1mm. I could not see any movement at the inner part of the arc.

So it seems as though David was correct all along. The change in overhang through an arm height adjustment of 3.0mm with a 12' tonearm is not detectible by eye and only barely visible through a 10X loupe magnification. As shown previously, the change in VTF is also extremely small and does not change if measured to 1/10th of a gram and it is only barely detectible if measured to 1/100th of a gram at the extremes of my 2.5mm changes in arm height.

Perhaps others can try to do these measurements and get different results, but based on my fairly careful attempts to understand what is going on at this extremely small scale using typical analog measurement devices for cartridge and arm set up, I can only conclude that the changes or effects that I hear in sonics when adjusting arm height are primarily the result of SRA changes of 1/10th of a degree for each 0.5mm change in arm height, and not the almost undetectable changes in the other parameters of VTF and overhang. This is as I suspected, but I wanted to see the actual data collected when trying to measure this stuff.

View attachment 40439