You nailed it

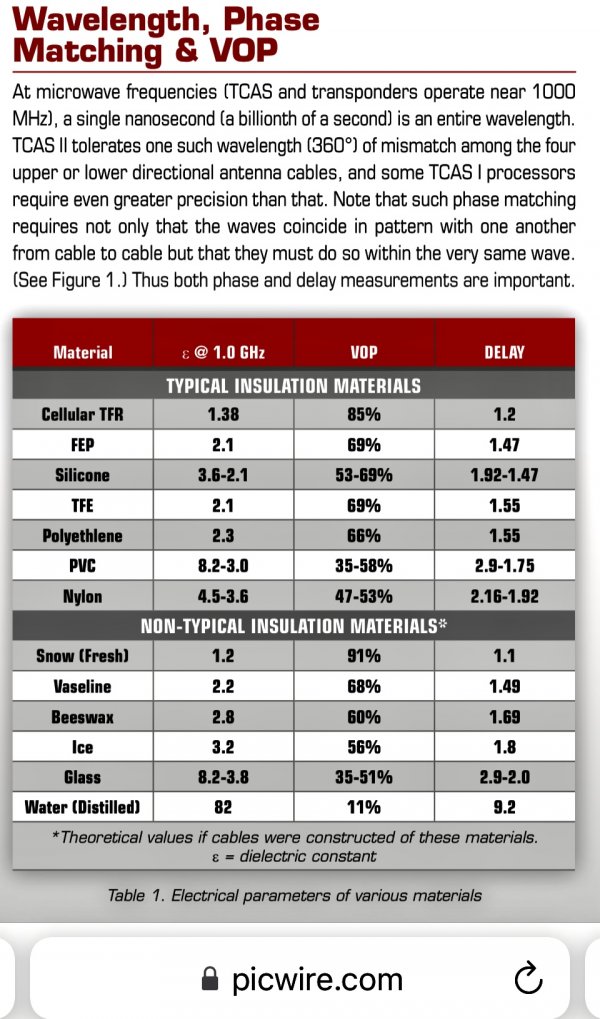

dielectric of the insulation is important. theoretically, air is the best insulator. but it doesn't work with cables, which is why plastics FPTE, FEP or cotton are extremely good. they prevent charge packets from sticking to the insulation and affecting signal speed.

Yes, air is best but then the wire corrodes, one thing many are not aware of, including cable designers it seems. There is also a myth that corrosion of wire doesn't matter, which is not true. I'd avoid cables that use air or fabric dielectrics with no way of preventing corrosion.

Another issue with insulation is triboelectric noise, caused by the friction between two materials generating electrical charge. Unfortunately conductors and insulation have some space between them on the triboelectric series, a list of materials in order of how quickly they develop a charge. So there is charge generated simply by moving and bending the cable, and in the case of an audio system you have the speakers output vibrating everything, so this is a real issue a vast majority of cable designers neglect. A new cable I've been working on makes for some massive improvements in this area as well as having a dielectric constant lower than teflon. It will objectively be the most technically advanced cable on the market, and unsurprisingly, it sounds better as a result. It has a more relaxed and clear sound vs teflon, it removes the last bit of haze and hardness you get with pure UPOCC silver cables with teflon insulation.