An excellent combination there Bill.I would install the Bergmann Odin. Possibly a Reed 5T too. Then a big beefy Glanz or FR66.

The New Acoustical System A*STELLAR turntable

- Thread starter Tango

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

agree. how it looks to me is that the long narrow arm board spot on the center rear of the plinth would be where some LT's would be attached; but it would be 'instead' of the left (possibly also instead of the 'right') rear spot. no way to use both places. it just gives you flexibility depending on the geometry of the LT.Do that and I dont think you can play your left rear arm. Most LTs take a lot of real estate and limit the ability to have 4 arms.

might someone be able to shoehorn 5 arms? too much work to be able to say no 100%. i'd be skeptical.

agree. how it looks to me is that the long narrow arm board spot on the center rear of the plinth would be where some LT's would be attached; but it would be 'instead' of the left (possibly also instead of the 'right') rear spot. no way to use both places. it just gives you flexibility depending on the geometry of the LT.

might someone be able to shoehorn 5 arms? too much work to be able to say no 100%. i'd be skeptical.

Hi Mike,

Even if one could shoehorn 5 arms onto the platform it would be horribly cumbersome to use it.

That said, I don’t personally see as a drawback. I personally don’t see the need for more than 3 arms really. 1 stereo, 1 mono, and 1 more stereo for a different flavour.

Probably this silver color will make the table sound bright. Anthracite probably a bit dark

Decisions … decisions …. probably there will be a stealth color option …

Decisions … decisions …. probably there will be a stealth color option …

Last edited:

Specs

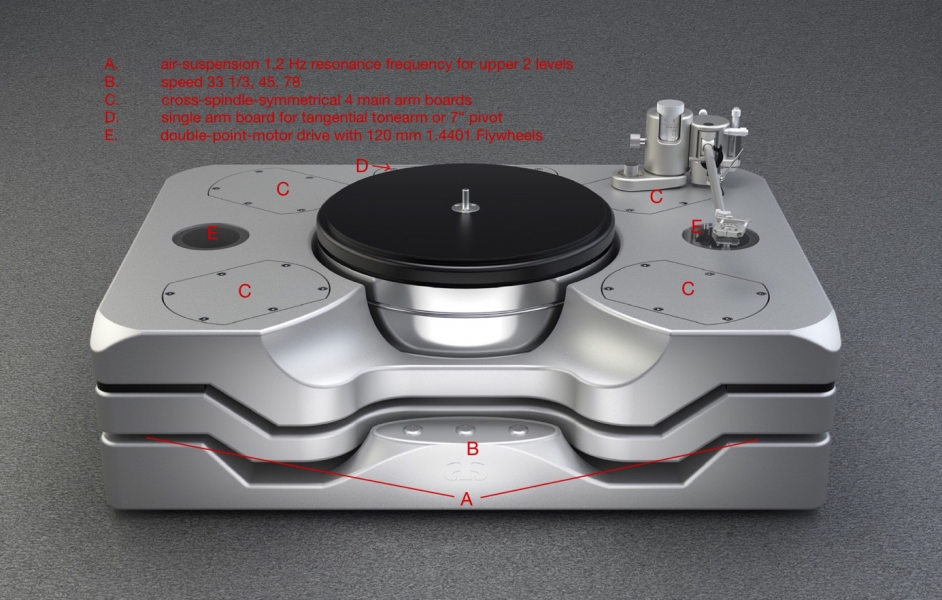

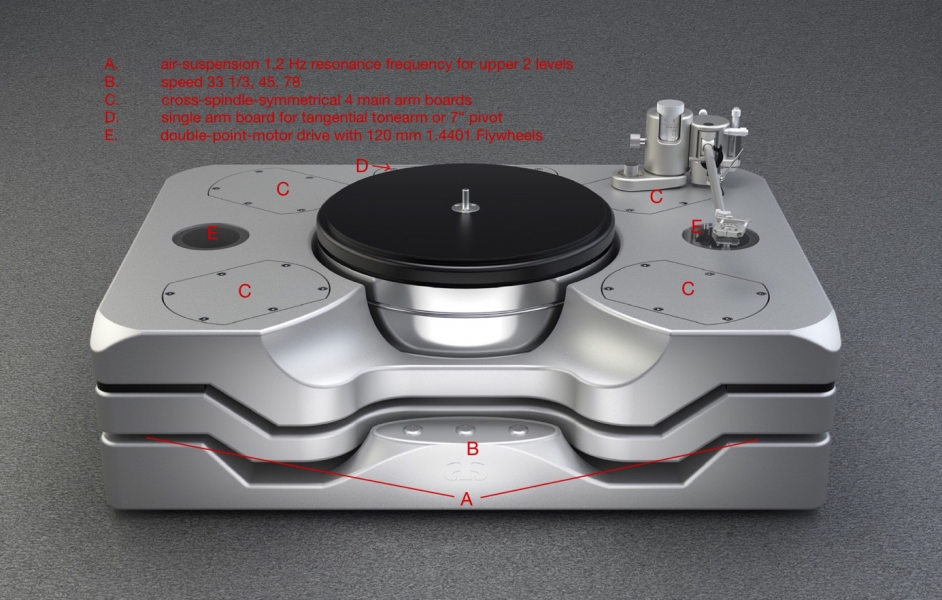

the A*STELLAR

- the ultimate turntable ..... reduced to the absolute maximum performance .... a turntable like no other features:

the A*STELLARs platter:

the A*STELLARs active dynamic drive

Depending on style of tangential tonearm mounted on rear center board, rear right board can still be used or not with 12” tonearm.

If tangential tonearm is mounted on center board left rear board cannot be used.

the A*STELLARs power supply

* external power supply 45 cm width x 38 cm depth x 14 cm height * cabinet in standard amplifier front plate design

* front plate available in silver or black

* 100V-240V – 50/60Hz

* including active motor management, full dc-supply, air suspension control.

* connection and wiring between power supply and turntable made & supplied by LEMO.

the A*STELLARs finish options

* available in choice of 5 selected standard finishes:

metallic-black, APOLYT-dark anthracite, dark-Titanium, Silver, light-Titanium.

* optional full battery powered and w/ incorporated automatic recharge logic (2nd power supply) 2nd power supply.

* optional special rack in 82 or 104 cm top-shelf height to incorporate shelves for 2 or 3 phono stage / line stage components and with air suspension!

* Acrylic hood for A*STELLAR turntable – dust and air-borne vibration shelter.

The A*STELLAR rack(s), acrylic hood and battery power supply to be introduced in June 2022.

As these do NOT require the multi-step production process of the A*STELLARs platter and plinth, these can be ordered at any time with our standard delivery time of 6-8 weeks on these components.

Ordering on racks, hood and battery power supply starting end July 2022.

the A*STELLAR

- the ultimate turntable ..... reduced to the absolute maximum performance .... a turntable like no other features:

the A*STELLARs platter:

- * an absolute unique 36 (thirty-six!) layers design platter, incorporating 18 different materials with defined energy transfer speed - combined in the optimum sequence.

- * incorporating Vinyl, Tungsten HD18, Titanium, AW6082 Alloy, 1.4401 Vanadium Steel - plus a defined mixture of organic material layers pressed together and bounded by natural resin.

- * Building on the unique APOLYT-concept inner platter design – and going beyond that.

- * the ASTELLAR's platter is 100% non-resonant, with a truly unique design concept featuring an absolute nonreflecting inner surface.

- * designed to provide the utmost possible pitch-black, deep dark "sonic background" - to allow the most tiny details to appear in an unforced and natural way and thus to integrate swift into the all-harmonic sonic picture provided with unheard before dynamic scale.

- * the platter’s spindle is fully decoupled and isolated from the bearing and featuring an inner thread to allow optimized coupling of vinyl record to material-identical platter surface by screw-on clamp as well as any record weight.

The A*STELLARs bearing:

* an unique bi-radial, factory adjustable push-pull, fully encapsuled and MU-screened magnetic bearing, completely maintenance-free - proving a perfect isolated, non-oszillating and totally vibration-free rotation. the A*STELLARs plinth: general- * full air-suspended plinth (bearing and tonearm levels) with 1.2 Hz resonance frequency.

- * plinth featuring 3 levels made from 3 different Aluminium alloys - with inlays of Titanium and vibration-absorbing gel.

- * true 3-point precision leveling with tilt-prevention

- * bearing level and tonearm level bound together with zero play, but further isolated by high density elastomer.

- * both air-suspended levels featuring different alloys - with decreasing energy transfer speed - and are CNC- carved from solid alloy cast blocks.

After CNC each solid level-plinth is again put in thermo-relaxed process before surface finishing.

This process is to avoid any inner tension in the plinth from the start – similar in effect to cryo-treatment in cables and connectors.

the A*STELLARs active dynamic drive

- * double-point brushless DC motor belt drive - with active dynamic control motor management - and free of any parasitic side force / drag applied to the platter.

- * Featuring the sample motor and motor management introduced in the APOLYT.

- * New “zero-sound” precision belt design used for absolute inaudible quite movement of belt.

- * The active motor management decreases gradually the inertia in the motor (NOT in the spinning system!) after selected speed is achieved.

- * double flywheel drive - with active regulated and monitored inertia incorporated by the active motor management.

- * totally decoupled bearing and tonearm mounting board from motor level by air-suspension + zero-vibration embedding of motor drive in base level plinth.

- * speed 33 1/3, 45 and 78 - all full stabilized with below 0.01 derivation from set speed.

the A*STELLARs plinth: tonearm level

- * arm boards in choice of Aluminium Alloy or Titanium with defined and maximized energy transfer.

- * pre-drilled and perfect positioned pre-cut arm boards supplied for each and all tonearms desired.

- * The A*STELLARS unique design of zero-tolerance cross-spindle-symmetry allows the mounting of the following

tonearm combinations installed:

Rear left board: 14”, 12”, 10”, 9” or 7” effective length pivot tonearm

Rear right board (main board): 12”, 10”, 9” or 7” effective length pivot tonearm- Front right board: 14”, 12”, 10”, 9” or 7” effective length pivot tonearm

Front left board: 12”, 10”, 9” or 7” effective length pivot tonearm

Rear center arm board: tangential tonearm or 7” effective length pivot tonearm

Depending on style of tangential tonearm mounted on rear center board, rear right board can still be used or not with 12” tonearm.

If tangential tonearm is mounted on center board left rear board cannot be used.

the A*STELLARs power supply

* external power supply 45 cm width x 38 cm depth x 14 cm height * cabinet in standard amplifier front plate design

* front plate available in silver or black

* 100V-240V – 50/60Hz

* including active motor management, full dc-supply, air suspension control.

* connection and wiring between power supply and turntable made & supplied by LEMO.

the A*STELLARs finish options

* available in choice of 5 selected standard finishes:

metallic-black, APOLYT-dark anthracite, dark-Titanium, Silver, light-Titanium.

- * on special request possible plinth finish in all Mercedes-Benz, BMW and Porsche colors (must be suitable for high temperature process: 180°/20 minutes).

- * pre-assembled in 5 units - none of them exceeding 27 kg gros weight - for easy and swift set-up.

- * gros dimensions: 69 cm x 48 cm x 23 cm.

- * gros footprint: 63 x 42 cm

- * net weight ASTELLAR turntable: 88 kg

- * net weight ASTELLAR power supply: 18 kg

* optional full battery powered and w/ incorporated automatic recharge logic (2nd power supply) 2nd power supply.

* optional special rack in 82 or 104 cm top-shelf height to incorporate shelves for 2 or 3 phono stage / line stage components and with air suspension!

* Acrylic hood for A*STELLAR turntable – dust and air-borne vibration shelter.

The A*STELLAR rack(s), acrylic hood and battery power supply to be introduced in June 2022.

As these do NOT require the multi-step production process of the A*STELLARs platter and plinth, these can be ordered at any time with our standard delivery time of 6-8 weeks on these components.

Ordering on racks, hood and battery power supply starting end July 2022.

Last edited:

Just replace the armboard with a cup holder.Not sure you can even use the front right in this setup.

Last edited:

Live the look of this tt. Looks like a battleship. Much better than some of the revolting oil rigs around today.

Why platter is made of 36 layers and 18 different materials? Would there be a compromise if it would have been made of 35 layers and 17 different materials? Why not 37 layers and 19 materials?

Even-though I like AS tonearms a lot I still have doubts about this turntable design approach.

Even-though I like AS tonearms a lot I still have doubts about this turntable design approach.

I understand the price @ 75k euro. Be interesting to see it on the forthcoming stand, wonder what the total weight will be?A gold and black version would be interesting.Specs

the A*STELLAR

- the ultimate turntable ..... reduced to the absolute maximum performance .... a turntable like no other features:

the A*STELLARs platter:

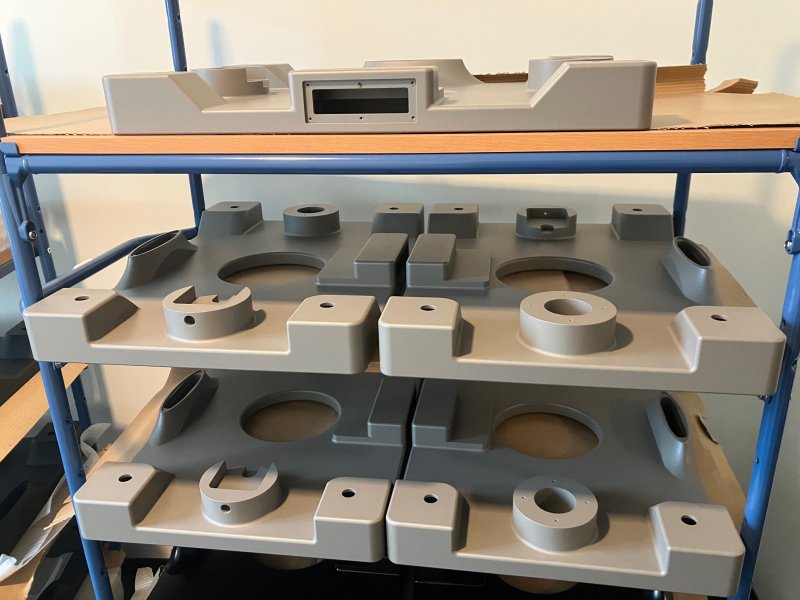

View attachment 93753

- * an absolute unique 36 (thirty-six!) layers design platter, incorporating 18 different materials with defined energy transfer speed - combined in the optimum sequence.

- * incorporating Vinyl, Tungsten HD18, Titanium, AW6082 Alloy, 1.4401 Vanadium Steel - plus a defined mixture of organic material layers pressed together and bounded by natural resin.

- * Building on the unique APOLYT-concept inner platter design – and going beyond that.

- * the ASTELLAR's platter is 100% non-resonant, with a truly unique design concept featuring an absolute nonreflecting inner surface.

- * designed to provide the utmost possible pitch-black, deep dark "sonic background" - to allow the most tiny details to appear in an unforced and natural way and thus to integrate swift into the all-harmonic sonic picture provided with unheard before dynamic scale.

- * the platter’s spindle is fully decoupled and isolated from the bearing and featuring an inner thread to allow optimized coupling of vinyl record to material-identical platter surface by screw-on clamp as well as any record weight.

The A*STELLARs bearing:

* an unique bi-radial, factory adjustable push-pull, fully encapsuled and MU-screened magnetic bearing, completely maintenance-free - proving a perfect isolated, non-oszillating and totally vibration-free rotation. the A*STELLARs plinth: general- * full air-suspended plinth (bearing and tonearm levels) with 1.2 Hz resonance frequency.

- * plinth featuring 3 levels made from 3 different Aluminium alloys - with inlays of Titanium and vibration-absorbing gel.

- * true 3-point precision leveling with tilt-prevention

- * bearing level and tonearm level bound together with zero play, but further isolated by high density elastomer.

- * both air-suspended levels featuring different alloys - with decreasing energy transfer speed - and are CNC- carved from solid alloy cast blocks.

After CNC each solid level-plinth is again put in thermo-relaxed process before surface finishing.

This process is to avoid any inner tension in the plinth from the start – similar in effect to cryo-treatment in cables and connectors.

the A*STELLARs active dynamic drive

* tonearm mounting boards with "zero-tolerance" embedding and mounting with automatic perfect re-location design: each tonearm mounted and aligned on one position can be moved to any of the other 3 positions without ANY re-alignment / recalibration needed.

- * double-point brushless DC motor belt drive - with active dynamic control motor management - and free of any parasitic side force / drag applied to the platter.

- * Featuring the sample motor and motor management introduced in the APOLYT.

- * New “zero-sound” precision belt design used for absolute inaudible quite movement of belt.

- * The active motor management decreases gradually the inertia in the motor (NOT in the spinning system!) after selected speed is achieved.

- * double flywheel drive - with active regulated and monitored inertia incorporated by the active motor management.

- * totally decoupled bearing and tonearm mounting board from motor level by air-suspension + zero-vibration embedding of motor drive in base level plinth.

- * speed 33 1/3, 45 and 78 - all full stabilized with below 0.01 derivation from set speed.

the A*STELLARs plinth: tonearm level

View attachment 93750 View attachment 93751

- * arm boards in choice of Aluminium Alloy or Titanium with defined and maximized energy transfer.

- * pre-drilled and perfect positioned pre-cut arm boards supplied for each and all tonearms desired.

- * The A*STELLARS unique design of zero-tolerance cross-spindle-symmetry allows the mounting of the following

tonearm combinations installed:

Rear left board: 14”, 12”, 10”, 9” or 7” effective length pivot tonearm

Rear right board (main board): 12”, 10”, 9” or 7” effective length pivot tonearm- Front right board: 14”, 12”, 10”, 9” or 7” effective length pivot tonearm

Front left board: 12”, 10”, 9” or 7” effective length pivot tonearm

Rear center arm board: tangential tonearm or 7” effective length pivot tonearm

View attachment 93752

Depending on style of tangential tonearm mounted on rear center board, rear right board can still be used or not with 12” tonearm.

If tangential tonearm is mounted on center board left rear board cannot be used.

the A*STELLARs power supply

* external power supply 45 cm width x 38 cm depth x 14 cm height * cabinet in standard amplifier front plate design

* front plate available in silver or black

* 100V-240V – 50/60Hz

* including active motor management, full dc-supply, air suspension control.

* connection and wiring between power supply and turntable made & supplied by LEMO.

the A*STELLARs finish options

* available in choice of 5 selected standard finishes:

metallic-black, APOLYT-dark anthracite, dark-Titanium, Silver, light-Titanium.

extra optional components:

- * on special request possible plinth finish in all Mercedes-Benz, BMW and Porsche colors (must be suitable for high temperature process: 180°/20 minutes).

- * pre-assembled in 5 units - none of them exceeding 27 kg gros weight - for easy and swift set-up.

- * gros dimensions: 69 cm x 48 cm x 23 cm.

- * gros footprint: 63 x 42 cm

- * net weight ASTELLAR turntable: 88 kg

- * net weight ASTELLAR power supply: 18 kg

* optional full battery powered and w/ incorporated automatic recharge logic (2nd power supply) 2nd power supply.

* optional special rack in 82 or 104 cm top-shelf height to incorporate shelves for 2 or 3 phono stage / line stage components and with air suspension!

* Acrylic hood for A*STELLAR turntable – dust and air-borne vibration shelter.

The A*STELLAR rack(s), acrylic hood and battery power supply to be introduced in June 2022.

As these do NOT require the multi-step production process of the A*STELLARs platter and plinth, these can be ordered at any time with our standard delivery time of 6-8 weeks on these components.

Ordering on racks, hood and battery power supply starting end July 2022.

The two motor two fly wheel design is interesting. I guess one takes apart the plinth to change the belt. The layer of air isolation in the mix is also interesting. This looks like a more practical solution one model down from the flagship standalone statement design, similar to the Air Force one and zero.

Damping from various materials in small amounts. Its supposed to be on Par with the Apolyt but with a smaller form factor.Why platter is made of 36 layers and 18 different materials? Would there be a compromise if it would have been made of 35 layers and 17 different materials? Why not 37 layers and 19 materials?

Even-though I like AS tonearms a lot I still have doubts about this turntable design approach.

Maybe too much of the same material might be a bad thing? or over damping at a particular frequency point?

Last edited:

Damping from various materials in small amounts. Its supposed to be on Par with the Apolyt but with a smaller form factor.

Maybe too much of the same material might be a bad thing? or over damping at a particular frequency point?

Constrained layering of materials has long been shown to an effective way of mitigating resonance issues and I can’t only assume a similar strategy has been employed here. 18 different materials as here seems a little over engineered shall we say lol but I can see what the designer is hoping to achieve. Too much of the same material is usually a bad thing ime.

no plans to add a tt to the stable, but agree this one has that 'look' of something special. agree on the linear tracker comments. will be curious whether the Primary Control can pull off the same magic tricks. probably some slightly different ones.

and, of course, plans can change. the sprouting uber tt merry-go-round does have my attention but only curious at this point.

and btw; your room is ready....but still no coffee.

Mike, did you consider this table when deciding to add a new TT to your collection?

Could not have said it better myselfI think it looks.....UGLY !

Similar threads

- Replies

- 0

- Views

- 270

- Replies

- 1

- Views

- 275

- Replies

- 8

- Views

- 439