Advice in buying a Studer A80

- Thread starter Tannoyista

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Okay.. I'll ask elsewhere... Thanks

You did not get any NO, please feel free to post them. Some people here service and enjoy their A80's.

Go out and buy an old Studer A80.

Then you can be a member of an exclusive club.

Well, sort of.

The marketing messaging behind the tape revival has consistently been that you only need to get a functioning tape transport of some kind and then change out the stock playback amplifier for something new.

Then, welcome to audio nirvana.

The psychology underlying this marketing scheme is brilliant, because coaxing the customer into getting deeply involved in how his resulting machine is modified, is a proven and powerful way to greatly raise his expectations.

Only when you look more closely at the science of analog tape playback, do the obvious cracks appear.

Eight-five percent of the engineering problem with tape transports is that they fail to deliver a flutter-free time base.

It's an especially huge problem with thirty or forty year old highest quality (and best sounding) machines like Studer A820s and A80s.

With relatively simple instrumentation, we can readily demonstrate that somebody's tape transport is seriously failing.

In the face of such audible time base corruption, listeners who nevertheless insist that they still find the sound quality from tape attractive, probably can't really be called audiophiles. At least not by any definition that I use.

To me, the notion that an old Studer A80 can be competently rebuilt by its new, non-expert owner is ludicrous.

Servo constant tension transports in this class are more than twenty times more complex than any turntable.

Yet, I'm clearly outnumbered by those who want you to think otherwise. So we have people selling do-it-yourself parts kits for A80 "overhauls".

Never mind that any real Studer expert would shudder at the notion of using those parts inside an A80.

Let's move on to a poster's recent mention of replacing his gold-colored Frako electrolytics in an A80.

Remember that Frako was once perhaps Germany's pre-eminent manufacturer of highest quality electrolytic capacitors. I have many here that are more than forty years old and still performing and measuring near their original specification. It's almost sad to preemptively change them in our remanufacturing.

Remember also that it was only a couple of the modern, compact form factor series (out of hundreds of gold-colored case Frako capacitor products made over decades) that were manufactured in the 1980s that developed reliability problems after only five or ten years in service.

Unfortunately, the issue showed up principally in the flagship Studer A820.

Always the same few capacitors. It was a minor embarrassment to both companies.

But a do-it-yourselfer looking at any old Studer with a mandate to shotgun any electrolytic with the name Frako is arguably misinformed and misdirected. Too often, the most consequential result of this approach is ruined circuit boards. That's actually harming the machine. Hurting its value.

So, does the tape hobby now intend to train its participants in expert-level thru-hole pcb soldering rework? And then do the same with do-it-yourself precision radial ball-bearing replacement, using bearings sourced from after-market tape machine parts suppliers who appear to be clueless of how Studer specified their bearings?

And then train owner-users in wide-band FFT flutter analysis to verify their end results?

That's kind of a tall order, in my opinion. But the market speaks much louder than I do.

Then you can be a member of an exclusive club.

Well, sort of.

The marketing messaging behind the tape revival has consistently been that you only need to get a functioning tape transport of some kind and then change out the stock playback amplifier for something new.

Then, welcome to audio nirvana.

The psychology underlying this marketing scheme is brilliant, because coaxing the customer into getting deeply involved in how his resulting machine is modified, is a proven and powerful way to greatly raise his expectations.

Only when you look more closely at the science of analog tape playback, do the obvious cracks appear.

Eight-five percent of the engineering problem with tape transports is that they fail to deliver a flutter-free time base.

It's an especially huge problem with thirty or forty year old highest quality (and best sounding) machines like Studer A820s and A80s.

With relatively simple instrumentation, we can readily demonstrate that somebody's tape transport is seriously failing.

In the face of such audible time base corruption, listeners who nevertheless insist that they still find the sound quality from tape attractive, probably can't really be called audiophiles. At least not by any definition that I use.

To me, the notion that an old Studer A80 can be competently rebuilt by its new, non-expert owner is ludicrous.

Servo constant tension transports in this class are more than twenty times more complex than any turntable.

Yet, I'm clearly outnumbered by those who want you to think otherwise. So we have people selling do-it-yourself parts kits for A80 "overhauls".

Never mind that any real Studer expert would shudder at the notion of using those parts inside an A80.

Let's move on to a poster's recent mention of replacing his gold-colored Frako electrolytics in an A80.

Remember that Frako was once perhaps Germany's pre-eminent manufacturer of highest quality electrolytic capacitors. I have many here that are more than forty years old and still performing and measuring near their original specification. It's almost sad to preemptively change them in our remanufacturing.

Remember also that it was only a couple of the modern, compact form factor series (out of hundreds of gold-colored case Frako capacitor products made over decades) that were manufactured in the 1980s that developed reliability problems after only five or ten years in service.

Unfortunately, the issue showed up principally in the flagship Studer A820.

Always the same few capacitors. It was a minor embarrassment to both companies.

But a do-it-yourselfer looking at any old Studer with a mandate to shotgun any electrolytic with the name Frako is arguably misinformed and misdirected. Too often, the most consequential result of this approach is ruined circuit boards. That's actually harming the machine. Hurting its value.

So, does the tape hobby now intend to train its participants in expert-level thru-hole pcb soldering rework? And then do the same with do-it-yourself precision radial ball-bearing replacement, using bearings sourced from after-market tape machine parts suppliers who appear to be clueless of how Studer specified their bearings?

And then train owner-users in wide-band FFT flutter analysis to verify their end results?

That's kind of a tall order, in my opinion. But the market speaks much louder than I do.

I have two acquaintances, both of whom own '64 Chevy Corvette Sting Rays. One of these persons bought the car, took it to a well-known Corvette restoration company (not far from where I live, actually), and spent nearly $100,000 to have the car completely rebuilt from the ground up. It looks and performs exactly like new (actually, probably better than new, since the restorer probably took more care in reassembling the Corvette than the original Chevy line workers who built it did).

The second acquaintance bought a car in very good original condition. He has not done anything to this car other than routine maintenance, and replacement of items that would cause it not to run (e.g., the alternator; brake master cylinder, etc.). The car runs well, but there's not any question that it does not perform at its peak. Plus the seat upholstery is cracked and the dashboard has clearly seen better days.

Both acquaintances would sell their right arm before giving up their cars. Both find great joy in owning them, even if they only drive them a few hundred miles a year, on sunny days when the temperature is between 70-80 degrees.

Which ownership approach is better?

Or perhaps we should just note that these men have different goals in owning their cars, and appreciate that each goal makes sense to each individual's own circumstances.

John C.

The second acquaintance bought a car in very good original condition. He has not done anything to this car other than routine maintenance, and replacement of items that would cause it not to run (e.g., the alternator; brake master cylinder, etc.). The car runs well, but there's not any question that it does not perform at its peak. Plus the seat upholstery is cracked and the dashboard has clearly seen better days.

Both acquaintances would sell their right arm before giving up their cars. Both find great joy in owning them, even if they only drive them a few hundred miles a year, on sunny days when the temperature is between 70-80 degrees.

Which ownership approach is better?

Or perhaps we should just note that these men have different goals in owning their cars, and appreciate that each goal makes sense to each individual's own circumstances.

John C.

Go out and buy an old Studer A80.

Then you can be a member of an exclusive club.

Well, sort of.

The marketing messaging behind the tape revival has consistently been that you only need to get a functioning tape transport of some kind and then change out the stock playback amplifier for something new.

Then, welcome to audio nirvana.

The psychology underlying this marketing scheme is brilliant, because coaxing the customer into getting deeply involved in how his resulting machine is modified, is a proven and powerful way to greatly raise his expectations.

Only when you look more closely at the science of analog tape playback, do the obvious cracks appear.

Eight-five percent of the engineering problem with tape transports is that they fail to deliver a flutter-free time base.

It's an especially huge problem with thirty or forty year old highest quality (and best sounding) machines like Studer A820s and A80s.

With relatively simple instrumentation, we can readily demonstrate that somebody's tape transport is seriously failing.

In the face of such audible time base corruption, listeners who nevertheless insist that they still find the sound quality from tape attractive, probably can't really be called audiophiles. At least not by any definition that I use.

To me, the notion that an old Studer A80 can be competently rebuilt by its new, non-expert owner is ludicrous.

Servo constant tension transports in this class are more than twenty times more complex than any turntable.

Yet, I'm clearly outnumbered by those who want you to think otherwise. So we have people selling do-it-yourself parts kits for A80 "overhauls".

Never mind that any real Studer expert would shudder at the notion of using those parts inside an A80.

Let's move on to a poster's recent mention of replacing his gold-colored Frako electrolytics in an A80.

Remember that Frako was once perhaps Germany's pre-eminent manufacturer of highest quality electrolytic capacitors. I have many here that are more than forty years old and still performing and measuring near their original specification. It's almost sad to preemptively change them in our remanufacturing.

Remember also that it was only a couple of the modern, compact form factor series (out of hundreds of gold-colored case Frako capacitor products made over decades) that were manufactured in the 1980s that developed reliability problems after only five or ten years in service.

Unfortunately, the issue showed up principally in the flagship Studer A820.

Always the same few capacitors. It was a minor embarrassment to both companies.

But a do-it-yourselfer looking at any old Studer with a mandate to shotgun any electrolytic with the name Frako is arguably misinformed and misdirected. Too often, the most consequential result of this approach is ruined circuit boards. That's actually harming the machine. Hurting its value.

So, does the tape hobby now intend to train its participants in expert-level thru-hole pcb soldering rework? And then do the same with do-it-yourself precision radial ball-bearing replacement, using bearings sourced from after-market tape machine parts suppliers who appear to be clueless of how Studer specified their bearings?

And then train owner-users in wide-band FFT flutter analysis to verify their end results?

That's kind of a tall order, in my opinion. But the market speaks much louder than I do.

Fred,

It seems to me that semantics is the essence of our divergent advice - your definition of audiophile is quite different from that of the majority you refer that disagree with you, including mine.

We thank you for telling us frontally about the difficulties and risks of tape machine re-furbishing, but IMHO telling a newcomer to WBF who wants to start a thread on buying/rebuilding an A80 to not do it, even he does it just for his enjoyment and learning, risks to be understood as pushing people out of this forum, something no one wants, I think.

One of the reasons of the existence of WBF is just to provide an open space where people have different views of this hobbycan share their experiences and free opinions.

Please note that I learned a lot from you concerning the three areas you refer along many years - I deeply respect your expertise. And my advice concerns only the Studer A80, that can be easily bought at considerable low cost as we have many tens of them relinquished in warehouses, and accessible reasonable quality parts, even if they are far from perfect. It will not bankrupt aficionados and will give them a lot of fun - yes, many people are in the high-end for music and fun. BTW, I would never give such advice on a A820. IMHO, YMMV.

Just being curious: what would be the result of wide band FFT flutter analysis of well tuned STUDER A80, A820 v.s. Nagra T-Audio? What signature would appear for different transport design?

How about OTARI MTR-15? AMPEX APR-102? Lyrec PTR-1 "Frida"? Telefunken M15/M15A? SONY APR-5000?

Also STUDER A810, A812, A816? A807? ReVox C270?

Another camp STUDER D820?

Can we perform flutter analysis using tradition spectrum analyzer? Or Tektronix's MDO?

Audio Precision gears were expansive; they accomplish their task automatically. I do own several Tektronix old stuff: SG505, SG5010, AA5009, all designed by Audio Precision's founding members. But still need a spectrum analyzer.

I had also collected some US' technical wonder: Tektronix 7104, R7844, R7903, 466, 485, 5116, 2467B etc.

Their list price were extremely high, even compared to STUDER A820.

How about OTARI MTR-15? AMPEX APR-102? Lyrec PTR-1 "Frida"? Telefunken M15/M15A? SONY APR-5000?

Also STUDER A810, A812, A816? A807? ReVox C270?

Another camp STUDER D820?

Can we perform flutter analysis using tradition spectrum analyzer? Or Tektronix's MDO?

Audio Precision gears were expansive; they accomplish their task automatically. I do own several Tektronix old stuff: SG505, SG5010, AA5009, all designed by Audio Precision's founding members. But still need a spectrum analyzer.

I had also collected some US' technical wonder: Tektronix 7104, R7844, R7903, 466, 485, 5116, 2467B etc.

Their list price were extremely high, even compared to STUDER A820.

Last edited:

. . . what would be the result of wide band FFT flutter analysis of well tuned STUDER A80, A820 v.s. Nagra T-Audio?

What signature would appear for different transport design? . . .

You have great questions. (But way too many of them for me to attempt to answer here. So I'm selecting from them.)

Curiously, most tape hobby people active on the forums appear not the least bit interested in flutter performance. They only want to talk about their outboard "tape stages".

But if we are addressing flutter, suffice to say that in my view, the machine designs to beat remain the A80 and A820.

That's it.

Yet, you probably appreciate that after all these years, the measured flutter on such old machines can be atrocious.

(Very often is. Many people apparently don't care. So we are left asking, can't they hear this?)

The Nagra T-Audio?

Stare at the T-Audio headblock architecture and it's immediately apparent that this high scrape flutter design was never an attempt at elevating the state-of-the-art for music recording.

The T-Audio was obviously designed for sophisticated professional sound for picture, time-code recording and editing applications. This was a specialty area where Nagra had impressive market dominance.

. . . Can we perform flutter analysis using tradition spectrum analyzer? . . .

Yes.

Many "traditional" spectrum analyzers are perfectly fine for FFT analysis of the time base accuracy of analog tape transports.

I'm still using a 33 year old Hewlett Packard 3561A, from 1985. And it's fine.

All you need to do is select an appropriate time record length and bandwidth for the time domain data acquisition.

. . . Or Tektronix's MDO? . . .

Absolutely.

The modern Tektronix MDO's with a spectral analysis option are simply astonishing in comparison to what was the state of the art in 1985. Arguably way overkill for what we need to look at in tape transports. But amazingly powerful.

Just being curious: what would be the result of wide band FFT flutter analysis of well tuned STUDER A80, A820 v.s. Nagra T-Audio? What signature would appear for different transport design?

How about OTARI MTR-15? AMPEX APR-102? Lyrec PTR-1 "Frida"? Telefunken M15/M15A? SONY APR-5000?

Also STUDER A810, A812, A816? A807? ReVox C270?

Another camp STUDER D820?

Can we perform flutter analysis using tradition spectrum analyzer? Or Tektronix's MDO?

Audio Precision gears were expansive; they accomplish their task automatically. I do own several Tektronix old stuff: SG505, SG5010, AA5009, all designed by Audio Precision's founding members. But still need a spectrum analyzer.

I had also collected some US' technical wonder: Tektronix 7104, R7844, R7903, 466, 485, 5116, 2467B etc.

Their list price were extremely high, even compared to STUDER A820.

Please see this thread and the links posted in this thread https://www.whatsbestforum.com/showthread.php?23810-What-is-scrape-flutter , including http://www.manquen.net/manquendotnet/audio/ . It is all there. But it will take a considerable time to go through all that information.

But IMHO unless you understand why you need the instrument and what you want to do with it, it is meaningless debating it.

Thank you Fred and microstrip for pointing out the link of flutter analysis. When I started collecting professional tape machines since 2011 the last measuring instrument I intended to get was flutter meter. Why? My reason was this instrument will give you a number but you hardly have any mean to DO SOMETHING about IT. Now it became clear that any minute degradation of tape transport path , e.g. worn ball bearing or dried lubrication, roller with trace of tape residue etc, would leave an unique fingerprint on the background; be it either a playback or a recording session.

Had you ever closely inspect the reflection of light from shinning back side of old brown tape passing through any transport element? Or use a two channel oscilloscope to monitor both input sine wave and also the recorded and reproduced signal? Even in time domain we can sense that transporting tape smoothly at any speed was a daunting task! Even though I haven't got a decent spectrum analyzer capable of low frequency I know that switch to frequency domain will reveal more details we do not want to face.

It will be great if the pioneering experts could shed some light on what we could do to correct any of these defects.

Had you ever closely inspect the reflection of light from shinning back side of old brown tape passing through any transport element? Or use a two channel oscilloscope to monitor both input sine wave and also the recorded and reproduced signal? Even in time domain we can sense that transporting tape smoothly at any speed was a daunting task! Even though I haven't got a decent spectrum analyzer capable of low frequency I know that switch to frequency domain will reveal more details we do not want to face.

It will be great if the pioneering experts could shed some light on what we could do to correct any of these defects.

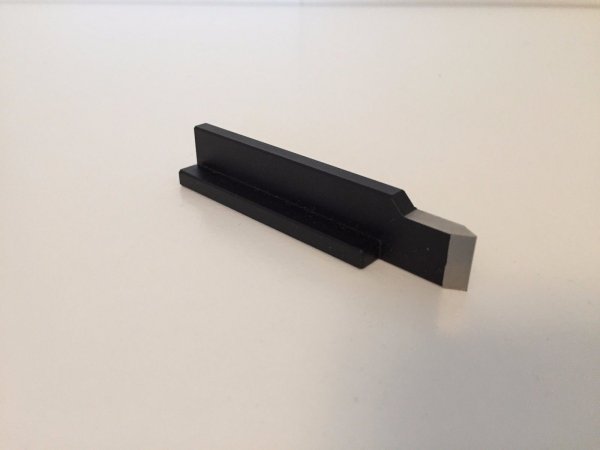

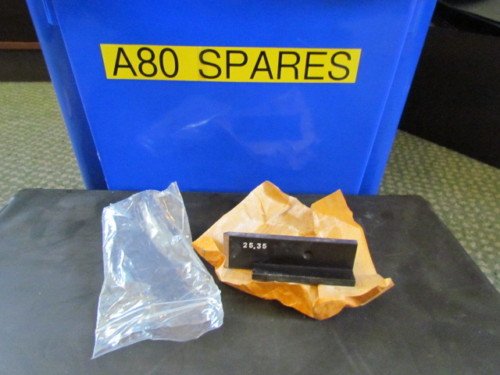

Looking for some other information in my Studer A80 folders I found these pictures of the famous A80 gauges - all we would need is accurate dimensions or measurements of them.

View attachment 59509View attachment 59510

Attachments

Thanks! All we need know is a drawing and some instructions on how to use it.

WBF moderators should give you an immediate trophy for posting this rare information on this forum!

WBF moderators should give you an immediate trophy for posting this rare information on this forum!

Instructions? its a Studer, instructions are in the manual.

I suggest the A820MCH manual, I think it has the best pictures. But read them all, they're free in pdf.

https://www.reeltoreel.nl/studer/

I suggest the A820MCH manual, I think it has the best pictures. But read them all, they're free in pdf.

https://www.reeltoreel.nl/studer/

Instructions? its a Studer, instructions are in the manual.

I suggest the A820MCH manual, I think it has the best pictures. But read them all, they're free in pdf.

https://www.reeltoreel.nl/studer/

Thanks - I only looked in the A80 manuals.

Here is a good adres for proper restored studers and other brands

A 100 % restored / calibrated A 80 without meter bridge (which is flimsy anyway )will set you back 6 K euros.

He has several at the moment.

Audioclassica.de which is : Eternal arts audio.

Brg hj

A 100 % restored / calibrated A 80 without meter bridge (which is flimsy anyway )will set you back 6 K euros.

He has several at the moment.

Audioclassica.de which is : Eternal arts audio.

Brg hj

Here is a good adres for proper restored studers and other brands

A 100 % restored / calibrated A 80 without meter bridge (which is flimsy anyway )will set you back 6 K euros.

He has several at the moment.

Audioclassica.de which is : Eternal arts audio.

Brg hj

Wow, this makes my Studer A80's valuable!

I dont know i d have to ask them

But if i would do a restauration , i would send a letter to skf for advice or just take skf and be done with it .

You can order closed bearings with a nylon cover instead of metal.

That sounds more logical to me, if off course the nylon cover can take the motor heat , the metal cover i think is standard in the studers, and skf has these off course as well

All this talk about special bearings.

Our company uses skf in much more challenging environments then a relativy slow rotating tape recorder at room temp.

What i know is that bearing manufacturing has moved forward compared to a made in the 60 s ties type bearing .

Skf has ultra modern facilities .

Brg hj

But if i would do a restauration , i would send a letter to skf for advice or just take skf and be done with it .

You can order closed bearings with a nylon cover instead of metal.

That sounds more logical to me, if off course the nylon cover can take the motor heat , the metal cover i think is standard in the studers, and skf has these off course as well

All this talk about special bearings.

Our company uses skf in much more challenging environments then a relativy slow rotating tape recorder at room temp.

What i know is that bearing manufacturing has moved forward compared to a made in the 60 s ties type bearing .

Skf has ultra modern facilities .

Brg hj

Last edited:

They are now restoring my B 62 and telefunken M 15 A

They found a lot of mistakes already what the previous " restorer" either didnt see or did wrong .

These people know what they r e talking about .

They found a lot of mistakes already what the previous " restorer" either didnt see or did wrong .

These people know what they r e talking about .

Similar threads

- Replies

- 22

- Views

- 3K

- Replies

- 8

- Views

- 2K

- Replies

- 4

- Views

- 1K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |