They can go anywhere the ratings allow. They don't need a warmup since they have zero temperature coefficient, and their dissipation factor is similar to Teflon with a ruler flat curve when that is charted with respect to temperature.Thanks for idea Ralph. Are they position constrained (power supply, interstage, output), or can they go wherever there's value overlap?

When the amplifier power is at 10%, its incorrect to say the distortion is 'super low'... Its more accurate to simply say there is 'distortion that isn't too high'. As you know, its all about that first Watt, but even with 18 Watt at clipping, the 1 Watt distortion will be quite measurable and audible.I don’t know about how much you “need”. I have 18 SET watts into a 16 ohm load speaker that is 105 dB. I might use 10% of the power when I have it cranking, but the beauty of that is that the distortion is super low. it’s nice to be able to use a mere fraction of an amplifier’s power rating knowing you have the headroom but not needing it to keep distortion low.

Bypassing coupling caps is always tricky! The reason is the caps can have different speeds so this can contribute to smearing at high frequencies. The more transparent the system the easier this is to hear (its also measurable, not that that matters on this thread...). For this reason, to get the best out of a coupling cap you just have to give it your best shot and no bypassing. Generally this means a Teflon cap because:The other tweak to try is to replace the polypropylene capacitors that bypass the electrolytic capacitors with a Jensen copper foil in oil of the same value. I did that in my Cary amps and liked it a lot. Use the same value and connections as the polypropylene capacitor being replaced.

Oil fill caps that we have tested have often displayed electrical leakage, although all the examples we've tested with this problem have been paper and oil. We've not encountered this problem with the ODAM caps from VH Audio. If the cap has leakage (which is not physical leaking) it will be a small DC Voltage at the output of the part where there should be none at all. This can throw off the operating point of the tube receiving the signal (such as the bias of a power tube). In the case of a power tube this can result in shorter tube life, distortion (because if the tube is over-biased distortion will rise) and possibly damage to an output transformer and/or power transformer. You don't run into this problem with Teflon parts.

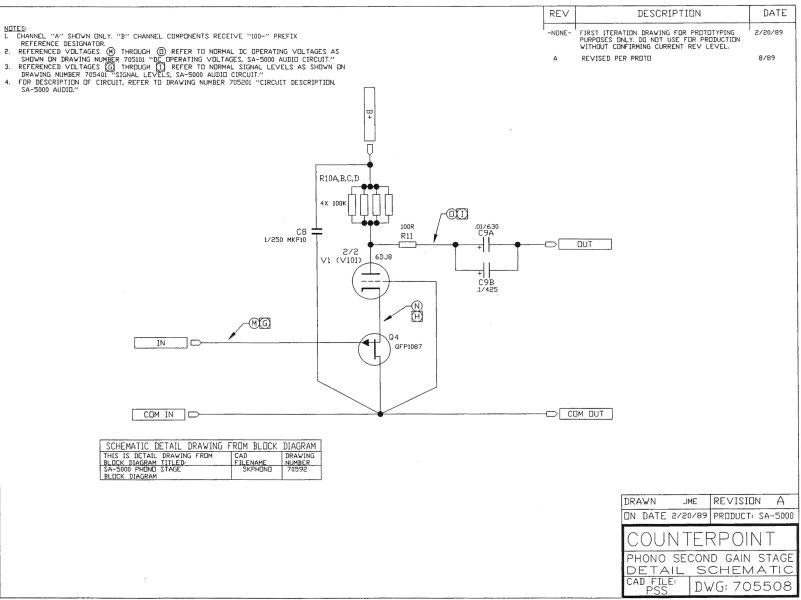

Coupling caps are a good reason to consider direct-coupling between the driver and power tube. If the driver is a cathode-follower, the power tube can obtain its bias from the driver tube and a much smaller coupling cap can be employed at the input to the driver tube. The smaller the coupling cap you can use without running into a LF cutoff problem, the more transparent the capacitor can be.