Technics SP-10 MKII

- Thread starter mep

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Couldn't be much Kachi. I don't know how some people look themselves in the mirror. After I received my money back via Pay Pal, I sent this chump a blistering email to let him know what I thought of his wasting my time and sending me such a poorly made and finished product. His response? "You get what you pay for" and "get a life."

Does anyone know of any downside to having a plinth built from a billet of aluminum? It will be strong, dimensionally stable, and non-resonant.

Strong? yes. Dimensionally Stable? Yes ... I don't know but am not sure about non-resonant ...

Frantz-Unlike platters made from cast aluminum that can ring like a bell unless they are damped, you are talking about a solid billet of 6061-T6 aluminum. Have you ever tried the knuckle test on a billet of aluminum?. Machining amps and preamps out of billets of aluminum seem to be all the rage now and I don't know why it wouldn't work for a plinth.

Mark

Mark

Hi Mark,

As Frantz suggested, I am not sure about it being non-resonant either. I might also be somewhat concerned about static charge discharges. I know that I get them frequently walking across the carpet when wearing certain shoes in particular and having the static charge discharge on the aluminum columns on my racks as well as the aluminum chassis/face plates of components like my amps and my ARC LS10.

Rich

As Frantz suggested, I am not sure about it being non-resonant either. I might also be somewhat concerned about static charge discharges. I know that I get them frequently walking across the carpet when wearing certain shoes in particular and having the static charge discharge on the aluminum columns on my racks as well as the aluminum chassis/face plates of components like my amps and my ARC LS10.

Rich

Rich-I get big static discharges in the winter time when I walk across my carpet and touch my gear. I usually try and discharge against the rack and not touch my preamp. But static electricity is a different issue and I would like to understand if there are other problems associated with making a plinth from a billet of aluminum that I need to know about.

Mark

Mark

Bruce B

WBF Founding Member, Pro Audio Production Member

garylkoh

WBF Technical Expert (Speakers & Audio Equipment)

Mark, I wonder if making it out of solid cell-cast acrylic might make it sound better than aluminum and be cheaper too? I'm not a big fan of metal (says the guy who makes all metal-coned loudspeakers).

Bruce B

WBF Founding Member, Pro Audio Production Member

Mark, I wonder if making it out of solid cell-cast acrylic might make it sound better than aluminum and be cheaper too? I'm not a big fan of metal (says the guy who makes all metal-coned loudspeakers).

It worked for Clearaudio!

If you can afford it nothing sounds better than brass/bronze, and it's a soft enough metal to work with.

I once found a piece at a scrap metal yard which had a oxidized patina copper look to it. I used it for my office sign, clear acrylic over it with vinyl letters. Point being, be creative and make the best of what you find.

I did use aluminum and acrylic on my own turntable project.

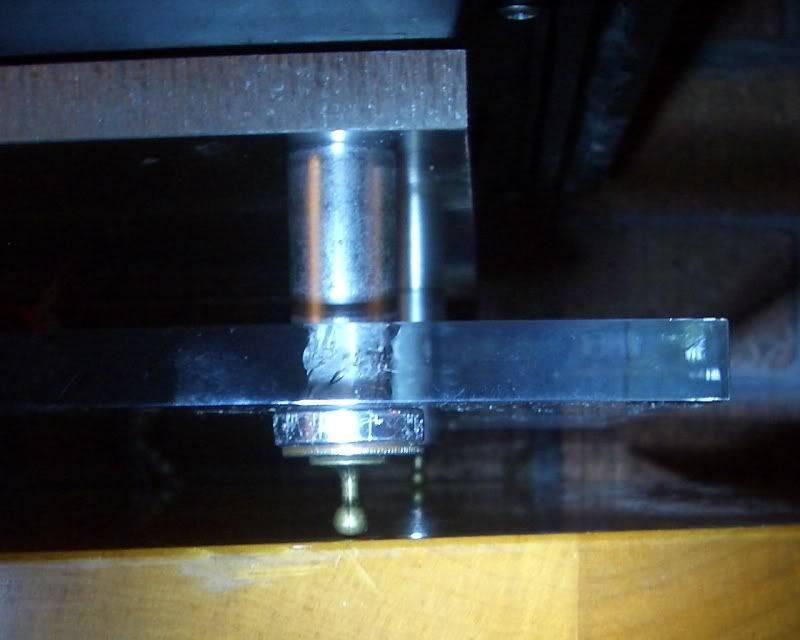

The underside:

http://www.martinloganowners.com/forum/showthread.php?t=10139

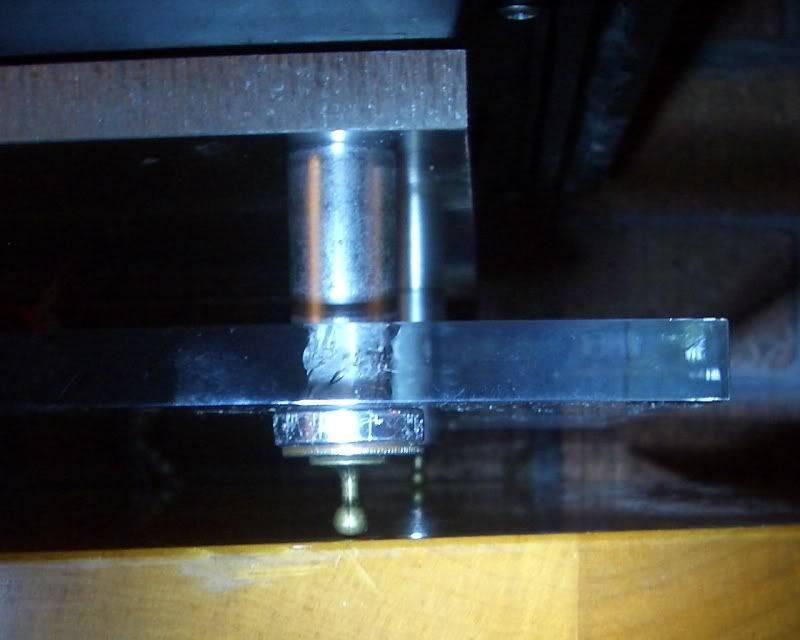

Simple feet - brass buttons:

http://www.martinloganowners.com/forum/showthread.php?t=10139

I once found a piece at a scrap metal yard which had a oxidized patina copper look to it. I used it for my office sign, clear acrylic over it with vinyl letters. Point being, be creative and make the best of what you find.

I did use aluminum and acrylic on my own turntable project.

The underside:

http://www.martinloganowners.com/forum/showthread.php?t=10139

Simple feet - brass buttons:

http://www.martinloganowners.com/forum/showthread.php?t=10139

The more I think about it, I don't see any any reason why billet aluminum wouldn't work just dandy. After all, people seem to love Magico speakers and the new ones are made from billet aluminum. If aluminum billet was going to be a problem with audio gear, it seems likely the first place it would show up would be a speaker with an enclosure made from aluminum. If it were prone to vibration and ringing, you couldn't ask for a more hostile environment than a speaker enclosure. Lots of surface area to be potentially affected by the sound pressure waves. YG Acoustics uses aluminum billet as well. If it can work for very expensive speakers, I can't think of a single reason why it wouldn't work as a plinth. They are both exposed to the same environment and they are both hosting transducers.

MEP, have you seen this TT project?

http://www.whatsbestforum.com/showthread.php?1349-The-story-of-my-Mitsubishi-LT-5V-turntable.

My sign:

http://www.whatsbestforum.com/showthread.php?1349-The-story-of-my-Mitsubishi-LT-5V-turntable.

My sign:

Attachments

Have you tried searching some of the the DIY forum for ideas?

Example:

http://www.diyaudio.com/forums/analogue-source/67089-corian-turntable-fun.html

You might want to build the base and turntable stand up as one solid piece. Just an idea, while you are in there.

Old thread on some interesting stands:

http://www.martinloganowners.com/forum/showthread.php?p=135804#post135804

Example:

http://www.diyaudio.com/forums/analogue-source/67089-corian-turntable-fun.html

You might want to build the base and turntable stand up as one solid piece. Just an idea, while you are in there.

Old thread on some interesting stands:

http://www.martinloganowners.com/forum/showthread.php?p=135804#post135804

I have been contacted by George to look at your SP-10II "plinthing" problems!

Funny enough,lately a friend of mine has asked for my opinion on exactly the same project!

So you can say that i have already formulated some thoughts about how i would make such a project.

I would suggest a metal chassis with layers of aluminum and bronze or leaded iron.

I would certainly put the arm on a separate plinth (a rectangular base alongside the main chassis) that could be arranged

to look "identical" to the power supply so that it could produce a "symmetrical" looking design.

Different metals have different resonant frequencies so a sandwich construction (with a little extra dampening) could be a good step towards making a "dead" plinth!

I would follow the same route for the tonearm base...With a design like this the tonarm base will be VERY heavy and rock solid!

My friend is considering this solution or a "panzerholz" design...

Problem is the cost!

Perhaps you could contact some local CNC shops and ask for prices.

I don't think that it would be any more expensive that the "boutique" wooden plinths that you are considering!

Funny enough,lately a friend of mine has asked for my opinion on exactly the same project!

So you can say that i have already formulated some thoughts about how i would make such a project.

I would suggest a metal chassis with layers of aluminum and bronze or leaded iron.

I would certainly put the arm on a separate plinth (a rectangular base alongside the main chassis) that could be arranged

to look "identical" to the power supply so that it could produce a "symmetrical" looking design.

Different metals have different resonant frequencies so a sandwich construction (with a little extra dampening) could be a good step towards making a "dead" plinth!

I would follow the same route for the tonearm base...With a design like this the tonarm base will be VERY heavy and rock solid!

My friend is considering this solution or a "panzerholz" design...

Problem is the cost!

Perhaps you could contact some local CNC shops and ask for prices.

I don't think that it would be any more expensive that the "boutique" wooden plinths that you are considering!

I have been contacted by George to look at your SP-10II "plinthing" problems!

Funny enough,lately a friend of mine has asked for my opinion on exactly the same project!

So you can say that i have already formulated some thoughts about how i would make such a project.

I would suggest a metal chassis with layers of aluminum and bronze or leaded iron.

I would certainly put the arm on a separate plinth (a rectangular base alongside the main chassis) that could be arranged

to look "identical" to the power supply so that it could produce a "symmetrical" looking design.

Different metals have different resonant frequencies so a sandwich construction (with a little extra dampening) could be a good step towards making a "dead" plinth!

I would follow the same route for the tonearm base...With a design like this the tonarm base will be VERY heavy and rock solid!

My friend is considering this solution or a "panzerholz" design...

Problem is the cost!

Perhaps you could contact some local CNC shops and ask for prices.

I don't think that it would be any more expensive that the "boutique" wooden plinths that you are considering!

Thanks for the response. I have given up on wooden plinths. I don’t see any need to have a separate chunk of metal for the tonearm to mount to. I only see this as introducing new problems of maintaining arm geometry. I think I’m going to stick with the KISS principle here and not mix and match metals. If Magico can make an entire large speaker enclosure from billet aluminum and not suffer resonance problems, I don’t know why a relatively small piece of billet aluminum would have any issues at all.

I'm a big fan of the KISS (Keep It Simple Stupid) method, but do plan everything through.If Magico can make an entire large speaker enclosure from billet aluminum and not suffer resonance problems,

Loudspeaker surfaces can transfer vibrating surface skin energy to the air without audible results. However the tiny voice coils in your cartridge may be a bit more sensitive to these effects.

I would look to other turntable projects before speaker projects in problem solving this one.

Just my two cents.

I would also consider or ask around (maybe ask Soundofvoid) why a arm on a separate plinth is a good idea.

Aside; I think that the glue between the layers of wood in a wood TT plinth do some constraining/dampening of frequency transfer. Glue or a mastic of some kind between layers of different metals or plastics could have the same affect.

Weigh the advice given and take your own path.

I understand your scepticism...

On my LT-5V i have used a 3cms thick 30X47 cm solid aluminum block as base.

When knocked on it ringed!

Upon checking with an accelerometer, matching two plates from different metals

makes a world of difference on vibration dampening.

Taking the arm out on a heavy separate plinth gives you thar extra level of insurance that any minute level of motor induced vibation

will not find it's way upwards to the tonearm.

I am not sure what is your experience with separate based tonearms but i assure you that with a 10 kilos base, you need something like

an earthquake to recheck (ever) the arm geometry!

I am sure that Magico (that you are so fond of) is doing a great work with a single metal, but i am also sure that it uses some very complex

construction/milling and i am also sure that some other materials are probably used to get this result.

With F.E.A and unlimited funds you can make a single metal construction immune enough to vibration but are you willing to go there?

On my LT-5V i have used a 3cms thick 30X47 cm solid aluminum block as base.

When knocked on it ringed!

Upon checking with an accelerometer, matching two plates from different metals

makes a world of difference on vibration dampening.

Taking the arm out on a heavy separate plinth gives you thar extra level of insurance that any minute level of motor induced vibation

will not find it's way upwards to the tonearm.

I am not sure what is your experience with separate based tonearms but i assure you that with a 10 kilos base, you need something like

an earthquake to recheck (ever) the arm geometry!

I am sure that Magico (that you are so fond of) is doing a great work with a single metal, but i am also sure that it uses some very complex

construction/milling and i am also sure that some other materials are probably used to get this result.

With F.E.A and unlimited funds you can make a single metal construction immune enough to vibration but are you willing to go there?

Similar threads

- Replies

- 1

- Views

- 696

- Replies

- 19

- Views

- 3K

- Replies

- 180

- Views

- 11K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |