Testing and embracing Stacore

- Thread starter flyer

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thank you very much guys for such a nice appreciation of our efforts! Actually in the real life the rack is surprisingly gentle looking (to my eyes and taste of course) but indeed in the best Bauhaus traditions its shape is dictated by the function. There are more pics coming with our new Roller platforms on top

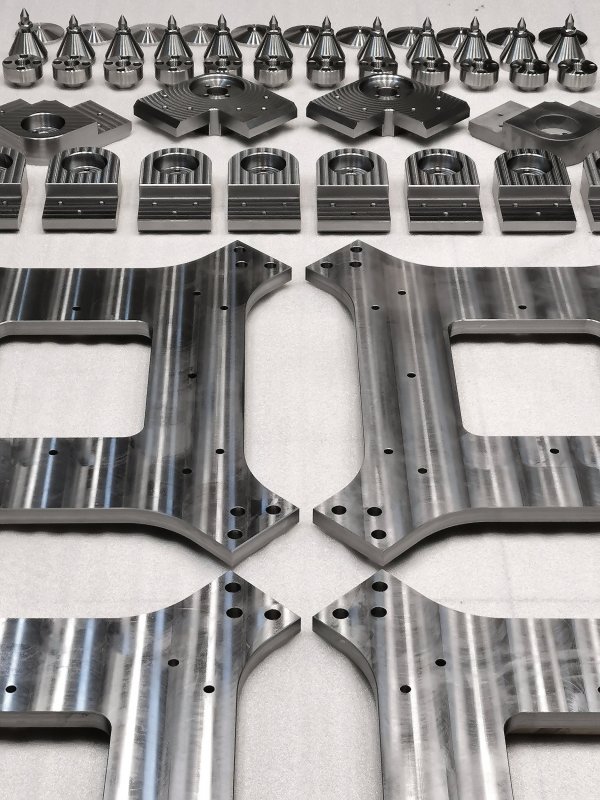

It's our new baby in the introductory range: Stacore Roller

Congratulatins Jarek, looks great!...and the finished construction. A double width amp stand with slate shelves.

View attachment 78411

david

Thank you David! Pure steel with a bit of slateCongratulatins Jarek, looks great!

david

Thank you Peter! The customer did not choose at this moment the pneumatic for reasons other than sonic. Actually pneumatic would be very desirable here given the proximity to the floor and to the speakers. He can add it at any moment.That looks great Jarek. Did the.customer not request a pneumatic component to the amp stand or is this a new concept/design?

Our Singapore distributor - Simplicity Control - is very creative. Guys tried screwing in our CLD footers to Magico’s with apparently remarkable sonic results.

Indeed, that is very creative!

I am just wondering what made you guys go for the Italian slate? Wish I knew more about it. Were you guys originally thinking about adopting a different material?

The mass combined with very good damping properties were the primal factors. It needed to be further dampened though to supress the natural slate colorations. What we did not know is how difficult it is to work with it (not sure how many companies are left on the market working with the slate, maybe 1-2).Indeed, that is very creative!

I am just wondering what made you guys go for the Italian slate? Wish I knew more about it. Were you guys originally thinking about adopting a different material?

What do you mean exactly? Is the the complexity of the process of dampening slate itself or does the dampening require special machines that are difficult to obtain/operate?What we did not know is how difficult it is to work with it

The surface is very very sensitive, the stone is soft, easily scratchable and absorbs all kinds of grease e.g. finger-prints like crazy. It needs careful honing to obtain a smooth surface, cannot be easily polished like marble, and needs oil impregnation to protect the surface. All by hand. Repeatable manufacture of high quality surfaces is a pain. Wood, MDF, plywood, metals, even cast iron, are orders of magnitude easier to work with.

Several years ago, I was a beta tester for the Stacore CLD footers that Jarek and Bodgan were developing. They are the perfect interface between electronics and the Stacore pneumatic platforms.

Recently, Jarek kindly proposed me to consider testing the CLD footers under my loudspeakers. He provided 2 sets of 4 footers with M10-M8 adaptors so I could screw the footers to my loudspeakers. With the help of my son, I ensured that the footers were tight locked to the loudspeakers.

With the CLD footers, the loudspeakers are literally “welded” to the concrete/tiles floor.

Comparative listening sessions demonstrated the superiority of the CLD footers over my previous set up: a better tonal balance with improved imaging. I could not believe the improvement I obtained from such small but clever and well-engineered devices.

Recently, Jarek kindly proposed me to consider testing the CLD footers under my loudspeakers. He provided 2 sets of 4 footers with M10-M8 adaptors so I could screw the footers to my loudspeakers. With the help of my son, I ensured that the footers were tight locked to the loudspeakers.

With the CLD footers, the loudspeakers are literally “welded” to the concrete/tiles floor.

Comparative listening sessions demonstrated the superiority of the CLD footers over my previous set up: a better tonal balance with improved imaging. I could not believe the improvement I obtained from such small but clever and well-engineered devices.

Thanks a lot for your answer. It sounds like there is a lot of technology involved in the production process.The surface is very very sensitive, the stone is soft, easily scratchable and absorbs all kinds of grease e.g. finger-prints like crazy. It needs careful honing to obtain a smooth surface, cannot be easily polished like marble, and needs oil impregnation to protect the surface. All by hand. Repeatable manufacture of high quality surfaces is a pain. Wood, MDF, plywood, metals, even cast iron, are orders of magnitude easier to work with.

Similar threads

- Replies

- 0

- Views

- 102

- Replies

- 11

- Views

- 1K

- Replies

- 20

- Views

- 1K

- Replies

- 6

- Views

- 330

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |