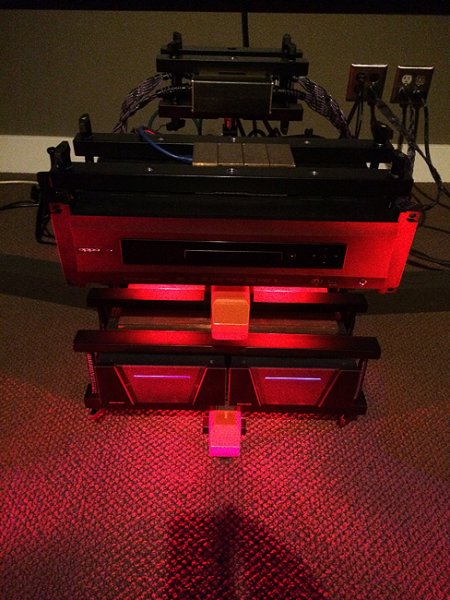

Edit: Just saw you posted images. Thanks for showing those.

Stehno, this clamping idea is pretty interesting. Which condition do you think would provide a better conduit for energy transmission: a very large solid plate the size of a component on both the top and the bottom plates of the component exerting fairly uniform pressure on the entire top and bottom surfaces (once footers have been removed), or a clamp that exerts its pressure on points arranged in particular locations on the top and bottom plates, or along the perimeter of the side plates? It seems to me that components generally have more solid side plates than top and bottom plates so the edges could take more compressive clamping force.

What do you think?

Peter, sorry I misunstood. I see what you mean now. Yes, one would assume that the sides and perimeter would be best mounting points, but I tried just that not long ago and surprisingly benefits were minimal. The heft of a solid top and bottom plates would most likely improve performance at least a bit. But without pressure point mounts, particularly close to where the power supply, a motor, etc, is located, performance benefits suffers much.

In essence, I think what you're suggesting is a bit of an external chassis with rigidity and heft surrounding and compressing the internal chassis. If the new outside bottom plate had some pressure points tight against the internal chassis bottom plate, particularly in strategic locations, and the whole new object was sufficiently mounted to the shelf as a single unit, then yes, it should work moderately to perhaps quite well. Then again, there needs to be some pressure points on top to sufficiently damp the top plate too - to ensure it no longer vibrates but hopefully transfer that energy there toward the outside perimeter.

As you seem to realize, there are numerous even extreme ways to skin this cat. But it's important to not forget the significance of completing the grounding of this energy to the sub-flooring system via the rack and its ability to continue that effort.

Early on, I used to say that the clamping was responsible for maybe 20 - 25% of the entire rack's overall performance. Icing on the cake is what I called it then. But with the way I do things today, I'd venture it's much closer to the 50 - 50 region. Definitely part of the cake.

When I launched my rack in 2010, I also granted Audio Horizons an exclusive license to just sell the clamps for customers to mount to existing shelves / racks. They didn't sell many, but of those who provided feedback, I think possibly every one of them said the clamps were the best kept secret in high-end audio.

But also bear in mind that whenever audio enthusiasts (including me) encounter a performance improvement that exceeds say 10 or 15%, it's often times interpreted as a life-changing experience and doing cartwheels in the streets.