Is there a clear and logical scientific reason why components work better Whe. 'burned in' and does this mean they deteriorate from optimal state shortly after having been burned in?

Why does burning in work

- Thread starter Loheswaran

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

the listener gets used to what their system sounds like.

The listener is by far the greatest variable in the system.

+1

The listener is by far the greatest variable in the system.

+1

Do components work better when burned in?

exactly ....... the term 'burned in' cracks me up. Conditioning, much more so of the individual than the gear.

Burning in works because after a time, excluding the first hour electronics are turned on when they are new or the first five minutes after that when turned on from cold ambient temperature; and 24 hours for a new speaker to get used to moving the physical cones and their surrounds, the listener gets used to what their system sounds like.

The listener is by far the greatest variable in the system.

how dare you express logic and common sense Gary ......... :b

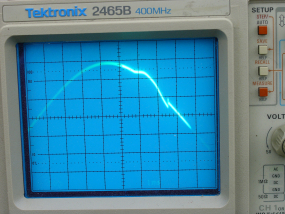

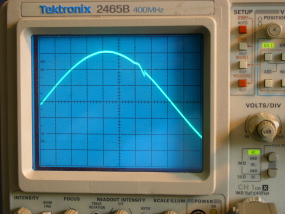

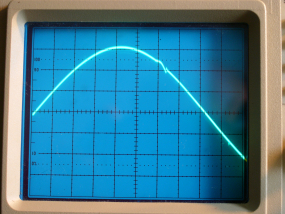

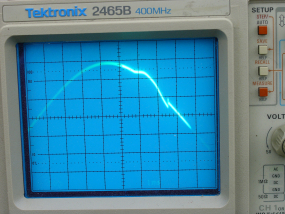

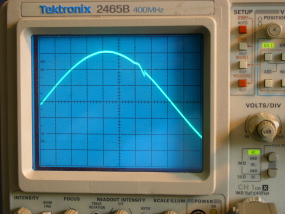

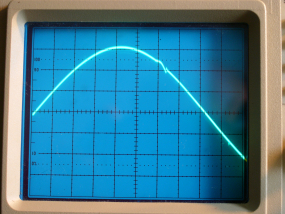

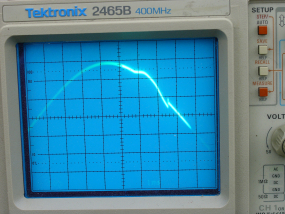

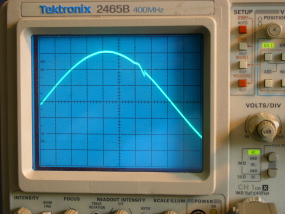

The subject of burn-in is deep, but here's a short and shallow summary. Electrical components will undergo permanent physical changes when voltage is applied to them and current flows, and this is a measurable effect. For example, I stole the pictures below from one of the many threads at diyaudio, on capacitor burn-in (off the shelf, one day, two days) http://www.diyaudio.com/forums/parts/81355-capacitor-burn-break.html

The same applies to warm-up, as the components settle when their temperature rises. For example, in amplifiers, the bias currents will settle; in loudspeakers, the voice coils will also change behavior (even worse here, they may deteriorate as the temperature rises even further than normal - simply put, their electrical characteristics change), etc.

The other side of burn-in is to catch early failures. Because of the effects of burn-in, any precise adjustments must follow that process, for best performance. Unfortunately, very few manufacturers do that, and it's disappointing. To give you a concrete personal example, when I got my XP-25 phono years ago, I sent it back within 10 days for re-adjustment. As the days went by, clearly the gain in one channel was higher, and clearly, the bass was ever so slightly different between the channels. Pass adjusted and sent it back at no charge.

The same applies to warm-up, as the components settle when their temperature rises. For example, in amplifiers, the bias currents will settle; in loudspeakers, the voice coils will also change behavior (even worse here, they may deteriorate as the temperature rises even further than normal - simply put, their electrical characteristics change), etc.

The other side of burn-in is to catch early failures. Because of the effects of burn-in, any precise adjustments must follow that process, for best performance. Unfortunately, very few manufacturers do that, and it's disappointing. To give you a concrete personal example, when I got my XP-25 phono years ago, I sent it back within 10 days for re-adjustment. As the days went by, clearly the gain in one channel was higher, and clearly, the bass was ever so slightly different between the channels. Pass adjusted and sent it back at no charge.

Is there a clear and logical scientific reason why components work better Whe. 'burned in' and does this mean they deteriorate from optimal state shortly after having been burned in?

Burn-in is a well documented process used during manufacturing for increasing reliability of some components. The physical changes in electronic components during the first tens or hundreds of hours are known, the only question is if they produce audible effects. As usual, the main question is on these thresholds and how we establish them - and here we do not have scientific answers. But we also do not have scientific answers why many amplifiers, preamplfiers or DACs sound much better after one hour warm-up. At best we measure some small differences, but are not able to correlate them with the great sound improvement most of us, me included, claim to perceive.

Some burn-in processes commonly used in research laboratories are not scientifically proved but based on experience - the oldest reference on cable burn-in I ever found was in an extremely sensitive Keithley Instruments electrometer manual referring that a specific Teflon cable should "rest" in position after being put in place before taking measurements!

Believe me, very seldom we will have scientific proves of anything in the high-end - science needs a lots of resources, time and money and scientists have better things to then explaining some subjective effects in stereo sound reproduction!

And yes, we should not mix burn-in as used in audiophilia, with burn-in carried in controlled challenging conditions to catch failures or estimate longevity and reliability.

We had several very interesting threads on this subject before - just google WBF on " burn-in".

(...) For example, I stole the pictures below from one of the many threads at diyaudio, on capacitor burn-in (off the shelf, one day, two days) http://www.diyaudio.com/forums/parts/81355-capacitor-burn-break.html

Although not documented and disputed in the thread, these pictures show a signal taken directly from a circuit using electrolytic capacitors - known to need a long burn-in. A good example of the "decay time" after burn-in is that some standards ask for re-forming before measuring electrolytic capacitor leakage :

3.7.6 Reforming

To IEC 60384-4, aluminum electrolytic capacitors are to be subjected to a reforming process before

acceptance testing. The purpose of this preconditioning is to ensure that the same initial conditions

are maintained when comparing and assessing different products.

For this purpose, the rated voltage is applied to the capacitors via a series resistance of approximately

100 ? for VR ?100 V DC, or 1000 ? for VR >100 V DC, for a period of one hour.

Subsequently, the capacitors are stored under no-voltage conditions for 12 to 48 hours at a temperature

between 15 and 35 °C. The leakage current must then be measured, at the latest after

48 hours.

If the capacitors meet the leakage current requirements without preconditioning, this procedure

can be omitted.

Empirical Audio

Industry Expert

Break-in is a phenomenon with dielectrics and speaker drivers.

Speaker drivers:

The surrounds are pliable, but until after are "worked", they become even more pliable. Sitting for long periods of time without usage stiffens these, so they need to be broken-in again, even older speakers. Also, shipping to shows subjects the drivers to changes in temperature and humidity, which can result in stiffening and the need for break-in again.

Electronics:

The dielectrics in circuit boards, cables and capacitors needs to "Form" when they are new. This process changes the molecular structure similar to the way the annealing changes the structure of metals or the right kind of light can change the energy level of some polymers. The Forming process applies electrical "stress" to the dielectric with voltage and current. Electrolytic capacitors have chemistry also that needs to form when they are new or have sit on the shelf for a long time.

When electronics is shipped, changes in temperature and humidity can cause static charge to build-up in dielectrics, so they need to be "worked" again to dissipate/drain this charge. Electrolytic caps may change chemistry, so they need to form again. This is why even older electronics needs break-in when setting up at shows. The last day of the show is usually the best as a result.

Steve N.

Empirical Audio

Speaker drivers:

The surrounds are pliable, but until after are "worked", they become even more pliable. Sitting for long periods of time without usage stiffens these, so they need to be broken-in again, even older speakers. Also, shipping to shows subjects the drivers to changes in temperature and humidity, which can result in stiffening and the need for break-in again.

Electronics:

The dielectrics in circuit boards, cables and capacitors needs to "Form" when they are new. This process changes the molecular structure similar to the way the annealing changes the structure of metals or the right kind of light can change the energy level of some polymers. The Forming process applies electrical "stress" to the dielectric with voltage and current. Electrolytic capacitors have chemistry also that needs to form when they are new or have sit on the shelf for a long time.

When electronics is shipped, changes in temperature and humidity can cause static charge to build-up in dielectrics, so they need to be "worked" again to dissipate/drain this charge. Electrolytic caps may change chemistry, so they need to form again. This is why even older electronics needs break-in when setting up at shows. The last day of the show is usually the best as a result.

Steve N.

Empirical Audio

The subject of burn-in is deep, but here's a short and shallow summary. Electrical components will undergo permanent physical changes when voltage is applied to them and current flows, and this is a measurable effect. For example, I stole the pictures below from one of the many threads at diyaudio, on capacitor burn-in (off the shelf, one day, two days) http://www.diyaudio.com/forums/parts/81355-capacitor-burn-break.html

The same applies to warm-up, as the components settle when their temperature rises. For example, in amplifiers, the bias currents will settle; in loudspeakers, the voice coils will also change behavior (even worse here, they may deteriorate as the temperature rises even further than normal - simply put, their electrical characteristics change), etc.

The other side of burn-in is to catch early failures. Because of the effects of burn-in, any precise adjustments must follow that process, for best performance. Unfortunately, very few manufacturers do that, and it's disappointing. To give you a concrete personal example, when I got my XP-25 phono years ago, I sent it back within 10 days for re-adjustment. As the days went by, clearly the gain in one channel was higher, and clearly, the bass was ever so slightly different between the channels. Pass adjusted and sent it back at no charge.

+1

What is to add, a book on mechanical audio engineering.

Break-in is a phenomenon with dielectrics and speaker drivers.

Speaker drivers:

The surrounds are pliable, but until after are "worked", they become even more pliable. Sitting for long periods of time without usage stiffens these, so they need to be broken-in again, even older speakers. Also, shipping to shows subjects the drivers to changes in temperature and humidity, which can result in stiffening and the need for break-in again.

Electronics:

The dielectrics in circuit boards, cables and capacitors needs to "Form" when they are new. This process changes the molecular structure similar to the way the annealing changes the structure of metals or the right kind of light can change the energy level of some polymers. The Forming process applies electrical "stress" to the dielectric with voltage and current. Electrolytic capacitors have chemistry also that needs to form when they are new or have sit on the shelf for a long time.

When electronics is shipped, changes in temperature and humidity can cause static charge to build-up in dielectrics, so they need to be "worked" again to dissipate/drain this charge. Electrolytic caps may change chemistry, so they need to form again. This is why even older electronics needs break-in when setting up at shows. The last day of the show is usually the best as a result.

Steve N.

Empirical Audio

+1

Part of that book.

+1

Part of that book.

Some excellent points there Steve, thanks for that information. This subject is still stuck in the 'believe' or 'not believe' camp, and some folk will never acknowledge it even exists for some reason. The science of it is fascinating, but I had heard enough of the condition to believe it. After a break of more than a week, my system sounds best 3 days after booting up, and I leave my SS power amp and power regenerator on all the time because of this very subject.

Burn-in is a well documented process used during manufacturing for increasing reliability of some components. The physical changes in electronic components during the first tens or hundreds of hours are known, the only question is if they produce audible effects. As usual, the main question is on these thresholds and how we establish them - and here we do not have scientific answers.

. . .

Well-stated! +1

Break-in is a phenomenon with dielectrics and speaker drivers.

Speaker drivers:

The surrounds are pliable, but until after are "worked", they become even more pliable. Sitting for long periods of time without usage stiffens these, so they need to be broken-in again, even older speakers. Also, shipping to shows subjects the drivers to changes in temperature and humidity, which can result in stiffening and the need for break-in again.

Electronics:

The dielectrics in circuit boards, cables and capacitors needs to "Form" when they are new. This process changes the molecular structure similar to the way the annealing changes the structure of metals or the right kind of light can change the energy level of some polymers. The Forming process applies electrical "stress" to the dielectric with voltage and current. Electrolytic capacitors have chemistry also that needs to form when they are new or have sit on the shelf for a long time.

When electronics is shipped, changes in temperature and humidity can cause static charge to build-up in dielectrics, so they need to be "worked" again to dissipate/drain this charge. Electrolytic caps may change chemistry, so they need to form again. This is why even older electronics needs break-in when setting up at shows. The last day of the show is usually the best as a result.

This is all fine but, the issue remains: Is any of it audible and can audibility be demonstrated under controlled conditions?

This is all fine but, the issue remains: Is any of it audible and can audibility be demonstrated under controlled conditions?

Careful Kal. You are starting to sound like some version of an "objectivist" and you may lose your "audiophile card". But welcome to the Dark Side.

And on this forum in particular, there are many who don't appreciate "listening under controlled conditions".

This is all fine but, the issue remains: Is any of it audible and can audibility be demonstrated under controlled conditions?

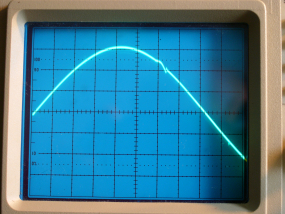

Audibility depends quite a bit on the wire used. It can range from subtle to fairly extreme. My litz-wire cables have fairly extreme burn-in and I did a trial measurement a while ago, mic is a couple inches from the center axis of a TAD Evolution series coaxial driver. Vertical scale is SPL in dB. I'm certainly not claiming this is definitive, but it is about what I expected and points to the fact a more in-depth test is warranted. I may do so one day, but I see very little benefit to doing all that work! I don't really care anymore if people want to believe in whatever, and the fact is presenting proof rarely results in people changing their opinion anyways. Those who don't believe will simply claim the test is not valid and then we'll argue about that. No thanks!

I also have some evidence in the fact I received several communications asking about this issue before I invested in an Audiodharma cable cooker and none after.

I think the litz wire has a more extreme burn-in as a result of the large surface area... the 20g wire is made using 250+ runs of individually insulated 44g wire, so this is a lot of insulation in contact with the conductor.

This is all fine but, the issue remains: Is any of it audible and can audibility be demonstrated under controlled conditions?

there 'ya go, demonstrating common sense again ...........

That is why we are stuck. You are right about the futility of changing most people's opinions but my criteria are pretty clear.I'm certainly not claiming this is definitive, but it is about what I expected and points to the fact a more in-depth test is warranted. I may do so one day, but I see very little benefit to doing all that work! I don't really care anymore if people want to believe in whatever, and the fact is presenting proof rarely results in people changing their opinion anyways.

Sure but that indicates that the test is refutable and inadequate.Those who don't believe will simply claim the test is not valid and then we'll argue about that.

This is all fine but, the issue remains: 1. Is any of it audible and 2. can audibility be demonstrated under controlled conditions?

How would you proceed for both?

• You are invited to test a brand new audio component*, fresh from the factory.

• It is for five weeks in a château of Provence (France) with all expenses paid, room & board.

• Your wife is also invited along with twenty more professional audiophiles with golden ears (trained listeners), and with their wives too.

• In that chateau everything is included; first class meals, best wines, infinite swimming pool, spa, sauna, manicure, forty bathrooms, many activities, plenty of gardens, horses, room service 24/24.

• Among the guests are the best in the audio business to conduct such tests.

• Also the very top best measuring tools are supplied.

* It could be a preamplifier, an amplifier, a loudspeaker, a DAC, ...all of them and more.

Last edited:

Sure but that indicates that the test is refutable and inadequate.

IME, there is no test on Earth, even if Einstein was alive and designed the test, that would satisfy a person with an ingrained belief system and an ego. People have to be beat over the head with many experiences that firmly contradict their beliefs and come to a point where it's more painful to hold onto the beliefs than to change them for them to even consider their beliefs were wrong.

If I simply send you a speaker cable made using the litz wire you might change your mind though. It's not subtle AT ALL.

Is high-end audio based on faith? ...On values? ...Or on balanced common sense? ...On hearing and listening? ...On reviews? ...On measurements? ...On everything?

Is there scientific evidence on burn-in audio/video products like OLED TVs and audio/video cables and DSP room corrections and acoustic systems music reproduction and hires music recordings in the analog and digital domains?

Are we in it for the pleasure or for something else only the blind can hear with better comprehension?

Is there scientific evidence on burn-in audio/video products like OLED TVs and audio/video cables and DSP room corrections and acoustic systems music reproduction and hires music recordings in the analog and digital domains?

Are we in it for the pleasure or for something else only the blind can hear with better comprehension?

Last edited:

Similar threads

- Replies

- 6

- Views

- 520

- Replies

- 1

- Views

- 212

- Replies

- 7

- Views

- 2K

- Replies

- 2

- Views

- 517

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |