Grounding Rod TLC

- Thread starter 2ndLiner

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I like my rod being moistened every other day, lol.My understanding is that grounding rods like moisture. To that end would it be wise to water the ground the rods are in regularly? If so, how often?

Duly noted…I like my rod being moistened every other day, lol.

My understanding is that grounding rods like moisture. To that end would it be wise to water the ground the rods are in regularly? If so, how often?

Stability is the key here. I'd leave it alone and let the soil manage it's own ability to release or hold moisture.

If it turns into a problem the solution is going to be installing new ones for better performance in drought like conditions.

Hi Al = I'm not sure what your first question is but regarding the second one, I have read on WBF where some people put a certain type of material around ground rods when installed to keep moisture in proximity. As I don't have that material in place I thought watering the soil where the ground rods are might compensate to a lesser degree...The rod of a what 8 foot r ten feet down how water is needed to wet the ground above to get to this depth ? and what is the point in this ?

I have read on WBF where some people put a certain type of material around ground rods

This is called a chemical ground. A copper ground rod is encased in conductive goop.

I have two of these chemical grounds, one vertical and one horizontal, to achieve a low resistance to ground even in the low ground moisture environment of Southern California.

Thanks, Ron! Do you think this goop is known to most electricians?This is called a chemical ground. A copper ground rod is encased in conductive goop.

I have two of these chemical grounds, one vertical and one horizontal, to achieve a low resistance to ground even in the low ground moisture environment of Southern California.

That made my evening lolI like my rod being moistened every other day, lol.

Technically a chemical ground rod is hollow core copper pipe filled with salts. The rod has perforated holes to weep the minerals into the surrounding earth.

Ron must have a normal copper clad rod that is potted in a clay like mateiral that is designed to maintain a stable moisture level.

A ground is influenced mostly by moisture, chemical make up of the surrounding earth, the rods contact with the esrth, depth, temperature and some other factors. How you attach the rod to the whole electrical system is also critical.

Why are you concerned? Do you have a lot of lightining or surges via the utility? I can give you the best ground in the world, but if I lift it while your playing music, I bet you won't hear I did.

You want a good ground to protect your gear. And you want good surge protective devices tied to said ground. But a good ground is not a path to quality music reproduction. Quality music reproduction when it comes to electricity is unrestricted current flow, copper copper copper and isolation transformers.

Ron must have a normal copper clad rod that is potted in a clay like mateiral that is designed to maintain a stable moisture level.

A ground is influenced mostly by moisture, chemical make up of the surrounding earth, the rods contact with the esrth, depth, temperature and some other factors. How you attach the rod to the whole electrical system is also critical.

Why are you concerned? Do you have a lot of lightining or surges via the utility? I can give you the best ground in the world, but if I lift it while your playing music, I bet you won't hear I did.

You want a good ground to protect your gear. And you want good surge protective devices tied to said ground. But a good ground is not a path to quality music reproduction. Quality music reproduction when it comes to electricity is unrestricted current flow, copper copper copper and isolation transformers.

Hi Rex, Michael of NorCal here. Thanks, in no small part to you, I have as good a power setup as my budget allowed. I was just wondering if there was a simple tweak possible. Hope you are weller than well!Technically a chemical ground rod is hollow core copper pipe filled with salts. The rod has perforated holes to weep the minerals into the surrounding earth.

Ron must have a normal copper clad rod that is potted in a clay like mateiral that is designed to maintain a stable moisture level.

A ground is influenced mostly by moisture, chemical make up of the surrounding earth, the rods contact with the esrth, depth, temperature and some other factors. How you attach the rod to the whole electrical system is also critical.

Why are you concerned? Do you have a lot of lightining or surges via the utility? I can give you the best ground in the world, but if I lift it while your playing music, I bet you won't hear I did.

You want a good ground to protect your gear. And you want good surge protective devices tied to said ground. But a good ground is not a path to quality music reproduction. Quality music reproduction when it comes to electricity is unrestricted current flow, copper copper copper and isolation transformers.

Higher the moisture content better the resistance. Lower the OHM reading. Consistent reading are just as important. Peat would be much better than sand, clay/rock not good, you got the point. Best way to install your ground rod ( can be done both vertically and horizontally ). Horizontally with rocky terrain. With 10' Ground rods auger the holes. 8" or 10" diameter. Nice if you know a well driller!! Encase the rods with Grounding Enhancement material, GEM is one product. Most codes now require 2 rods. Typical spacing is if using 10' rod 10' spacing. 6awg for bridging the rods. You want to trench the distance between the rods at least 2' deep. Make the bridge from the 2nd clamp to the next rod. You want to also encase the 6awg in the Ground Enhancement Material. You can put rock spacers under the 6awg so the material surrounds the wire. Ground rods have a life expectancy. They become scaled and less effective....

Copper is sensitive to all possible combinations of salts and especially to organic components (carbonic acid corrosion, bacteria).Technically a chemical ground rod is hollow core copper pipe filled with salts. The rod has perforated holes to weep the minerals into the surrounding earth.

Ron must have a normal copper clad rod that is potted in a clay like mateiral that is designed to maintain a stable moisture level.

A ground is influenced mostly by moisture, chemical make up of the surrounding earth, the rods contact with the esrth, depth, temperature and some other factors. How you attach the rod to the whole electrical system is also critical.

Why are you concerned? Do you have a lot of lightining or surges via the utility? I can give you the best ground in the world, but if I lift it while your playing music, I bet you won't hear I did.

You want a good ground to protect your gear. And you want good surge protective devices tied to said ground. But a good ground is not a path to quality music reproduction. Quality music reproduction when it comes to electricity is unrestricted current flow, copper copper copper and isolation transformers.

the better way is to use galvanized rods because they still have good contact with the ground even after ten years.

Exsample

That's a nice clean application. Where I live we have crawl spaces, basements are not typical. I had galvanized in the ground. It became scaled beyond recognition. The enhancement material should live for several decades...Copper is sensitive to all possible combinations of salts and especially to organic components (carbonic acid corrosion, bacteria).

the better way is to use galvanized rods because they still have good contact with the ground even after ten years.

Exsample

View attachment 111788

the big advantage of the 5 foot long cross grounding rod is that it has a larger contact surface than round rods. You can also use it underground, but then protect the cable connection against moisture. this is best made absolutely waterproof with a tar bandage.That's a nice clean application. Where I live we have crawl spaces, basements are not typical. I had galvanized in the ground. It became scaled beyond recognition. The enhancement material should live for several decades...

P.S

Definitely wear gloves, you can't get the tar off your fingers. even after washing your hands 10 times.

Last edited:

I don't think Cross Grounding rods are legal in the USA. They are not mentioned in the NEC. They seem to be a European product.

I use to specify using liquid tape, then vinyl tape over the top on the conductor to electrode connection. That is the place I see rods fail in the US. I can never seem to get the installing electricians to use the product. They kick and scream just having to use good materials and precision installation techniques.

Potting the rod and wire in ground enhancing material is a very good practice, but its cost prohibitive to have a driller make holes in your yard. And again, what is the point. Were not really getting rid of noise. Your not gong to hear a rod potted in GEM compared to a rod driven in the earth if they both have less than 5 ohms resistance. Both are going to fail if lightning hits the service stike on you home. You will be lucky if your house is still there after the strike. If you have dry sandy desert earth, I can ground it properly, but it takes money. I have to bring a 4 point earth resistance tester, take samples from all over, send them to a lab for analysis and a detailed plan on what to do. Usually its 4 or more chemical rods buried deep with a backhoe or well machine , maybe potted in GEM and cad welded together with 2/0. The material alone are around $20K or more. And you need land. Acres of land.

One of the most effective, least expensive grounds is a ufer installed when the home is built. BUT, a Ufer is rebar in your foundation. If you take a close lightining strike, its immediate intense heat in the concrete that explodes your foundation. Not good for your home. Everything has plusses and minus. You ground for the location and conditions.

I use to specify using liquid tape, then vinyl tape over the top on the conductor to electrode connection. That is the place I see rods fail in the US. I can never seem to get the installing electricians to use the product. They kick and scream just having to use good materials and precision installation techniques.

Potting the rod and wire in ground enhancing material is a very good practice, but its cost prohibitive to have a driller make holes in your yard. And again, what is the point. Were not really getting rid of noise. Your not gong to hear a rod potted in GEM compared to a rod driven in the earth if they both have less than 5 ohms resistance. Both are going to fail if lightning hits the service stike on you home. You will be lucky if your house is still there after the strike. If you have dry sandy desert earth, I can ground it properly, but it takes money. I have to bring a 4 point earth resistance tester, take samples from all over, send them to a lab for analysis and a detailed plan on what to do. Usually its 4 or more chemical rods buried deep with a backhoe or well machine , maybe potted in GEM and cad welded together with 2/0. The material alone are around $20K or more. And you need land. Acres of land.

One of the most effective, least expensive grounds is a ufer installed when the home is built. BUT, a Ufer is rebar in your foundation. If you take a close lightining strike, its immediate intense heat in the concrete that explodes your foundation. Not good for your home. Everything has plusses and minus. You ground for the location and conditions.

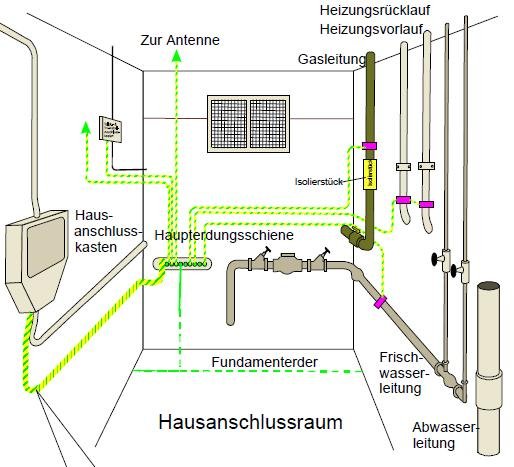

in Germany, two forms of grounding are permitted. in new buildings, concrete foundations in the basement are often used for grounding. when rebuilding the electrical systems in old houses, cross earth electrodes are used. both systems are allowed. the cable cross-section is prescribed at least 16mm (awg5) is then led to an equipotential bonding. From there, the fuse box, all pipe systems (natural gas, water and lightning protection are brought together. From experience as a trained electrician, I can say that both grounding systems are well below 5 ohms.I don't think Cross Grounding rods are legal in the USA. They are not mentioned in the NEC. They seem to be a European product.

I use to specify using liquid tape, then vinyl tape over the top on the conductor to electrode connection. That is the place I see rods fail in the US. I can never seem to get the installing electricians to use the product. They kick and scream just having to use good materials and precision installation techniques.

Potting the rod and wire in ground enhancing material is a very good practice, but its cost prohibitive to have a driller make holes in your yard. And again, what is the point. Were not really getting rid of noise. Your not gong to hear a rod potted in GEM compared to a rod driven in the earth if they both have less than 5 ohms resistance. Both are going to fail if lightning hits the service stike on you home. You will be lucky if your house is still there after the strike. If you have dry sandy desert earth, I can ground it properly, but it takes money. I have to bring a 4 point earth resistance tester, take samples from all over, send them to a lab for analysis and a detailed plan on what to do. Usually its 4 or more chemical rods buried deep with a backhoe or well machine , maybe potted in GEM and cad welded together with 2/0. The material alone are around $20K or more. And you need land. Acres of land.

One of the most effective, least expensive grounds is a ufer installed when the home is built. BUT, a Ufer is rebar in your foundation. If you take a close lightining strike, its immediate intense heat in the concrete that explodes your foundation. Not good for your home. Everything has plusses and minus. You ground for the location and conditions.

I don't know if that's not allowed in the USA. So first ask the energy supplier.

I can only say that in Germany there are probably the strictest regulations when it comes to the electrical installation of a house.

Exsample in germany grounding

The drawing looks exactly the same as the USA. But why wouldn't it be. Electricity does not see boarders, and I doubt planetary boundaries. We bond it all in can at the first point the utility drops the power in the building. Not in an external innersystem bonding jumper. With multiple power sources such as solar, wind and hydro and generators, that is happening in the transfer switch or hybrid inverter. Sometimes its a mess of $%&# in a wall crimped together.

And we have galvanized rods too. They are considerd inferior, but most people use them to save money.

I honestly don't know which looses its conductive attachment to earth faster. I have absolutly seen the connection point of wire to electode fails first. I also see stranded fails before solid, especially in earth. Chemical rods have a 20 year life. The salts eat them up. I assume any electrode in highly conductive earth is reacting with the soil and being eaten away faster than an electrode in poor soil. The life of your ground will also be influenced by the quality of your electrical system and whats attaches to the system. If you have a bunch of leaking voltage, the current is going to earth, and the electrode will see current and loose electrons to the surrounding environment. If there is no stray voltage, the electrode will have less reason to react with the surrounding soils.

Like I said above. I can get a 5 ohm ground anywhere. Just what will it take. In Houston Texas, they use a 1/2" copper rod. Just one. And its like 6 feet or so long. I don't rhink they are even 8 feet. And every one I tested was 2 ohms or so. In Arizona I know a guy who had 8 or 10 x 40 foot deep holes drilled in a star pattern, then an electode potted in each in GEM. The owner was sat down at a table and told his ground is so effective, it will draw lightining to it. He may consider installing a ligting shield. Something like a CMCE suppressor. But that may have pushed the strikes onto neighbors homes. So they let it hit earth. So far It stays in the earth and dos not come back into the structure.

And we have galvanized rods too. They are considerd inferior, but most people use them to save money.

I honestly don't know which looses its conductive attachment to earth faster. I have absolutly seen the connection point of wire to electode fails first. I also see stranded fails before solid, especially in earth. Chemical rods have a 20 year life. The salts eat them up. I assume any electrode in highly conductive earth is reacting with the soil and being eaten away faster than an electrode in poor soil. The life of your ground will also be influenced by the quality of your electrical system and whats attaches to the system. If you have a bunch of leaking voltage, the current is going to earth, and the electrode will see current and loose electrons to the surrounding environment. If there is no stray voltage, the electrode will have less reason to react with the surrounding soils.

Like I said above. I can get a 5 ohm ground anywhere. Just what will it take. In Houston Texas, they use a 1/2" copper rod. Just one. And its like 6 feet or so long. I don't rhink they are even 8 feet. And every one I tested was 2 ohms or so. In Arizona I know a guy who had 8 or 10 x 40 foot deep holes drilled in a star pattern, then an electode potted in each in GEM. The owner was sat down at a table and told his ground is so effective, it will draw lightining to it. He may consider installing a ligting shield. Something like a CMCE suppressor. But that may have pushed the strikes onto neighbors homes. So they let it hit earth. So far It stays in the earth and dos not come back into the structure.

Your fortunate to have a consistent 5 ohm, I would imaging your soil is loom. Most copper ground rods are minimum 8', mine are 10'. 5/8th is preferred over 1/2". Many electrical contractors will use the water line coming into the house as a ground. Which is effective. I'm on a well so this is not possible...The drawing looks exactly the same as the USA. But why wouldn't it be. Electricity does not see boarders, and I doubt planetary boundaries. We bond it all in can at the first point the utility drops the power in the building. Not in an external innersystem bonding jumper. With multiple power sources such as solar, wind and hydro and generators, that is happening in the transfer switch or hybrid inverter. Sometimes its a mess of $%&# in a wall crimped together.

And we have galvanized rods too. They are considerd inferior, but most people use them to save money.

I honestly don't know which looses its conductive attachment to earth faster. I have absolutly seen the connection point of wire to electode fails first. I also see stranded fails before solid, especially in earth. Chemical rods have a 20 year life. The salts eat them up. I assume any electrode in highly conductive earth is reacting with the soil and being eaten away faster than an electrode in poor soil. The life of your ground will also be influenced by the quality of your electrical system and whats attaches to the system. If you have a bunch of leaking voltage, the current is going to earth, and the electrode will see current and loose electrons to the surrounding environment. If there is no stray voltage, the electrode will have less reason to react with the surrounding soils.

Like I said above. I can get a 5 ohm ground anywhere. Just what will it take. In Houston Texas, they use a 1/2" copper rod. Just one. And its like 6 feet or so long. I don't rhink they are even 8 feet. And every one I tested was 2 ohms or so. In Arizona I know a guy who had 8 or 10 x 40 foot deep holes drilled in a star pattern, then an electode potted in each in GEM. The owner was sat down at a table and told his ground is so effective, it will draw lightining to it. He may consider installing a ligting shield. Something like a CMCE suppressor. But that may have pushed the strikes onto neighbors homes. So they let it hit earth. So far It stays in the earth and dos not come back into the structure.

Similar threads

- Replies

- 5

- Views

- 791

- Replies

- 0

- Views

- 1K

- Replies

- 5

- Views

- 653

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |