9N silver by acapella

- Thread starter dzdzdzln

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Few metallurgists would acknowledge the existence of silver purer than 4N in oxygenated air.

Few metallurgists would acknowledge the existence of silver purer than 4N in oxygenated air.

I can trust some factory can use 5N (japan oyaide) or 7N(Neotech ) mathod to make silver cable?maybe the cable is 4N last.

But I can't trust 9N

The wire must be processed in an inert gas atmosphere to achieve anything over 4N.

There is a BIG difference is sound going from 4N to 5N to UPOCC silver. I don't consider 4N silver a good conductor for audio use, UPOCC copper is better.

9N probably isn't measurable, but a theoretical... and unless it's continuous cast it'll have grain boundaries that will impact it's performance.

There is a BIG difference is sound going from 4N to 5N to UPOCC silver. I don't consider 4N silver a good conductor for audio use, UPOCC copper is better.

9N probably isn't measurable, but a theoretical... and unless it's continuous cast it'll have grain boundaries that will impact it's performance.

If someone tells you they have 6Ns purity its a very good idea to turn around and run as hard as you can unless a cliff or TRex is right behind you. 9Ns.... just laugh as hard as you can.

In short its simply not possible. This is just marketing plain and simple.

In short its simply not possible. This is just marketing plain and simple.

I think Mitsubishi is one of the major companies touting 6N or better, Acrolink has posted exact content of impurities, etc. The Ohno Continuous Casting Process patents describe the casting of 6N purity metals in inert gas atmosphere, etc. so I think that's proven, but once exposed to oxygen it will immediately corrode where exposed, but the rest of the insulated wire should be sealed from the atmosphere. This is also why I question cables made with textile dielectrics that allow exposure to air, it's a cable that will corrode over time and probably sounds worse and worse as time goes by... But imo purity makes a big difference, and 6N UPOCC metals are several percent more conductive on the IACS scale, this is an easily measurable difference and the difference in sound quality when used in audio systems is very obvious.

I think where high purity is often thought of as impossible is in the context of traditionally drawn wire, where the metal is repeatedly drawn through dies without necessarily being protected from oxygen by an inert gas shield.

High purity, 6N+, has also been impossible to confirm with conventional measurements but I believe the latest mass spectronomy techniques can indeed measure past 6N now.

I think where high purity is often thought of as impossible is in the context of traditionally drawn wire, where the metal is repeatedly drawn through dies without necessarily being protected from oxygen by an inert gas shield.

High purity, 6N+, has also been impossible to confirm with conventional measurements but I believe the latest mass spectronomy techniques can indeed measure past 6N now.

This is also why I question cables made with textile dielectrics that allow exposure to air, it's a cable that will corrode over time and probably sounds worse and worse as time goes by...

Why do you limit the concern to textile dielectrics? Teflon isn't air tight either.

Why do you limit the concern to textile dielectrics? Teflon isn't air tight either.

It is. You can remove teflon from wire after years and it's not oxidized.

Hmm, that is surprising. Either way, I would think silver oxide conducts well and may not have an effect on sonics like copper oxide likely would, being a semiconductor of sorts.

Not sure why it's surprising, that's exactly what electrical insulation is supposed to do, besides preventing the electrons from leaking I guess...

Silver doesn't just form silver oxide, there is also silver sulfide and it creates a black coating on silver.

It's possible to hear the difference between teflon and PE and PVC insulation, having a corrosive layer over your 6N+ UPOCC silver seems like a bad idea, and it's only going to get worse over time.

analogsa, you posted a few seconds before me.

It is. You can remove teflon from wire after years and it's not oxidized.

That is true, but isn't it also the case that to extrude teflon over silver, you have to run some pretty high temperatures?

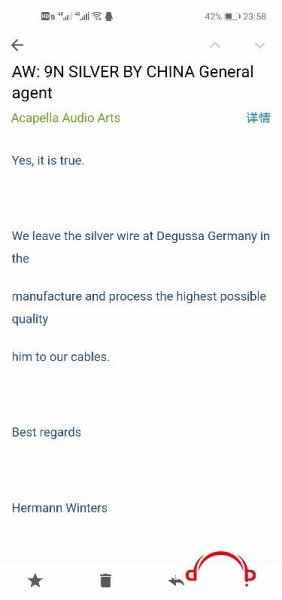

99.9% and 99.9999 to infinity is still only 99.9% ! This is all marketing nonsense by the metal producers, they're buying what Degussa is currently manufacturing. Infinitesimal amounts of supposed purity has no effect on sound either nor can anyone guarantee that 99.9% pure will sound superior to a conductor of even 95% purity. Sadly this irrelevant data has become high-end lore.

! This is all marketing nonsense by the metal producers, they're buying what Degussa is currently manufacturing. Infinitesimal amounts of supposed purity has no effect on sound either nor can anyone guarantee that 99.9% pure will sound superior to a conductor of even 95% purity. Sadly this irrelevant data has become high-end lore.

david

david

We can only dream. If anyone tells you they have this, it might be prudent to turn in the other direction and run really hard.9N copper or silver !!!

Yes sure, it seems all are marketing hype.We can only dream. If anyone tells you they have this, it might be prudent to turn in the other direction and run really hard.

the highest purity of silver, but you wouldn't want to build cables with that.

Similar threads

- Replies

- 2

- Views

- 192

- Replies

- 0

- Views

- 282

- Replies

- 8

- Views

- 1K

- Replies

- 0

- Views

- 500

- Replies

- 57

- Views

- 2K