Best capacitors for power amps...

- Thread starter Stereophonic

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The caps look top solder the trick is big tip to transfer heat fast this is best to not hurt the Board nor cap if done fast

another way is cut the old caps off then it’s just two exposed stubs to remove.

to put back is high heat big tip the do fast. The heat mist travel up from the bottom of the board to melt on top of board strips

it’s hard to know if the solder has done so.

another way is leave a small gap to look under caps

Then you know. At this point leave or heat fast and push down.

Brands have a sound and not all brands are made in trusted places anymore.

never buy on ama or flea markets you cannot trust them. you need a good trusted source.

there are date codes on the caps and new ones maybe be smaller or different values specs.

there are some comments on DIY websites

And makers can be misleading as to when or what to pic just as much as helpful.

amp looks very well made and easy to service.

my advice is change one channel and play to let burn in. you will hear a change and this helps to know it’s worth the effort and it also helps you know your work is done well. Use good high quality magnifying glasses or lighted glass. it’s very hard to see a bad solder joint at times.

solder suckers can cause damage as well as help.

Go slow and find a good method you have plenty to do lol.

exact values may not be possible but get very close. higher working temps is good

and ESR as well but ESR Alone is not always better.

even if you do one board at a time and burn in is good some caps on Boards closer to drivers or outputs have bigger changes then main psu caps.

good luck do post results

another way is cut the old caps off then it’s just two exposed stubs to remove.

to put back is high heat big tip the do fast. The heat mist travel up from the bottom of the board to melt on top of board strips

it’s hard to know if the solder has done so.

another way is leave a small gap to look under caps

Then you know. At this point leave or heat fast and push down.

Brands have a sound and not all brands are made in trusted places anymore.

never buy on ama or flea markets you cannot trust them. you need a good trusted source.

there are date codes on the caps and new ones maybe be smaller or different values specs.

there are some comments on DIY websites

And makers can be misleading as to when or what to pic just as much as helpful.

amp looks very well made and easy to service.

my advice is change one channel and play to let burn in. you will hear a change and this helps to know it’s worth the effort and it also helps you know your work is done well. Use good high quality magnifying glasses or lighted glass. it’s very hard to see a bad solder joint at times.

solder suckers can cause damage as well as help.

Go slow and find a good method you have plenty to do lol.

exact values may not be possible but get very close. higher working temps is good

and ESR as well but ESR Alone is not always better.

even if you do one board at a time and burn in is good some caps on Boards closer to drivers or outputs have bigger changes then main psu caps.

good luck do post results

One last thing very important always drain the caps voltage a big must. Use a low value 10 watt resistor

Measure dc voltage before and after very important

Measure dc voltage before and after very important

A final tip: do yourself a favor and use SN63 for your soldering. Stay away from SN60.... since no exotic materials are used on the boards or the parts themselves there's no point in using anything more exotic.

Thank you.

I’m not repairing myself the amp.

It is at https://dbtronic.es/.

Official Classé SAT.

They are going to use WBT Silver 4% solder.

I’m not repairing myself the amp.

It is at https://dbtronic.es/.

Official Classé SAT.

They are going to use WBT Silver 4% solder.

This is what I'm talking about. Silver will actually be a contaminant in the solderjoint since no silver or gold is used by the parts involved. So you're paying for an expensive solder with no benefit whatsoever. Solders like that are used to prevent gold, silver or rhodium from leaching into the solderjoint when such materials are present on the parts to be soldered together.Thank you.

I’m not repairing myself the amp.

It is at https://dbtronic.es/.

Official Classé SAT.

They are going to use WBT Silver 4% solder.

SN63 is used when you're dealing with copper and tin plated parts, such as the filter cap's leads. It is a eutectic solder like WBT's solders are, but a lot less expensive and in this case will give you as much or better benefit.

This is what I'm talking about. Silver will actually be a contaminant in the solderjoint since no silver or gold is used by the parts involved. So you're paying for an expensive solder with no benefit whatsoever. Solders like that are used to prevent gold, silver or rhodium from leaching into the solderjoint when such materials are present on the parts to be soldered together.

SN63 is used when you're dealing with copper and tin plated parts, such as the filter cap's leads. It is a eutectic solder like WBT's solders are, but a lot less expensive and in this case will give you as much or better benefit.

Aren't the WBT solders lead free?

I find it much harder to get a good joint with lead free solder.

WBT makes both leaded and lead free solder. I agree lead free solder is a PIA.Aren't the WBT solders lead free?

I find it much harder to get a good joint with lead free solder.

Do as atmosphere says it’s better to not use exotic stuff and silver I think melts hotter too

They probably are, as part of compliance with RoHS.Aren't the WBT solders lead free?

I find it much harder to get a good joint with lead free solder.

A lot of lead-free solders have higher melting temperatures- some as much as 100 degrees more. Some are not that much higher than regular solder.

If the solderjoint isn't good, it obviates any use of an exotic solder used to make it, wouldn't you think?

SN63 is still readily available. As long as the lead is not above a certain percentage of weight (0.1%) in the device in which its used, you stay in compliance with RoHS.

Solder material used, WBT-0820:

Answer from Classé SAT:

“This tin has a bit of lead in it.

And also for the welding to be durable, it must be so. For years and for environmental reasons, these tin alloys have been withdrawn from the European market.

In terms of confidence, it is quite negative since we are tired of seeing equipment with very few years and completely cracked welds. This tin is much better than lead free.

Reason for using silver in solder is that it makes that solder stronger and sits better in the track itself.”

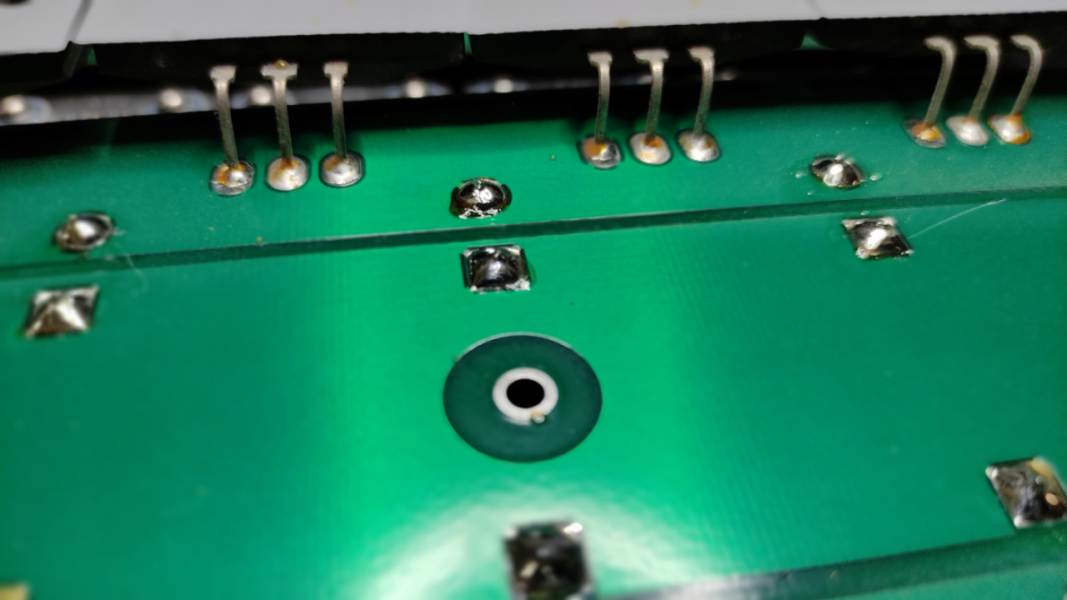

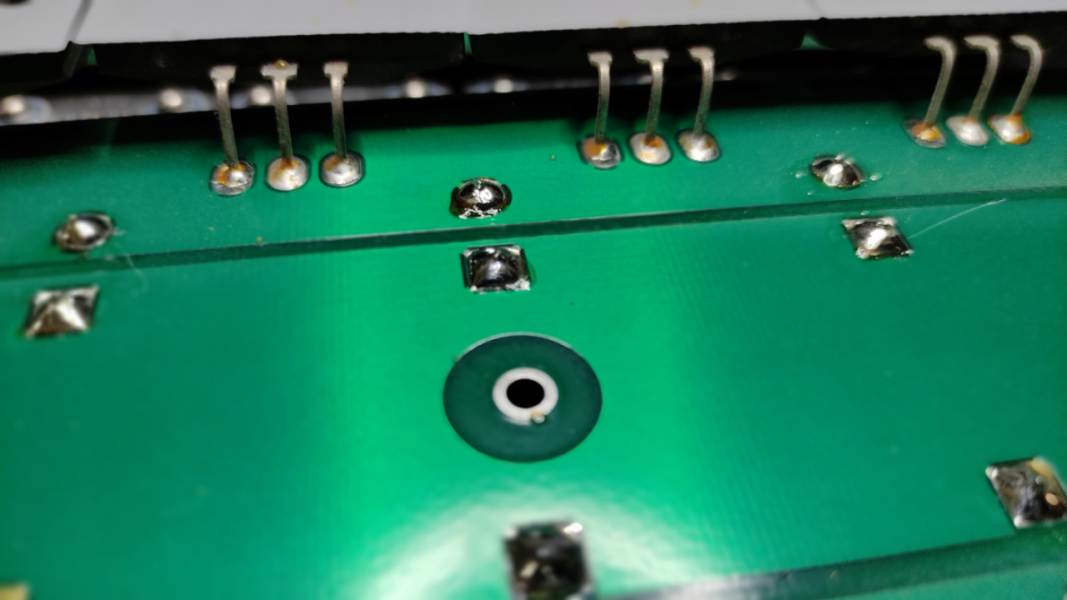

Final caps soldered…

Next step voltage and Bias potentiometer adjustment.

Great work !!!

Answer from Classé SAT:

“This tin has a bit of lead in it.

And also for the welding to be durable, it must be so. For years and for environmental reasons, these tin alloys have been withdrawn from the European market.

In terms of confidence, it is quite negative since we are tired of seeing equipment with very few years and completely cracked welds. This tin is much better than lead free.

Reason for using silver in solder is that it makes that solder stronger and sits better in the track itself.”

Final caps soldered…

Next step voltage and Bias potentiometer adjustment.

Great work !!!

Last edited:

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 0

- Views

- 1K

- Replies

- 20

- Views

- 8K

- Sticky

- Replies

- 826

- Views

- 104K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |