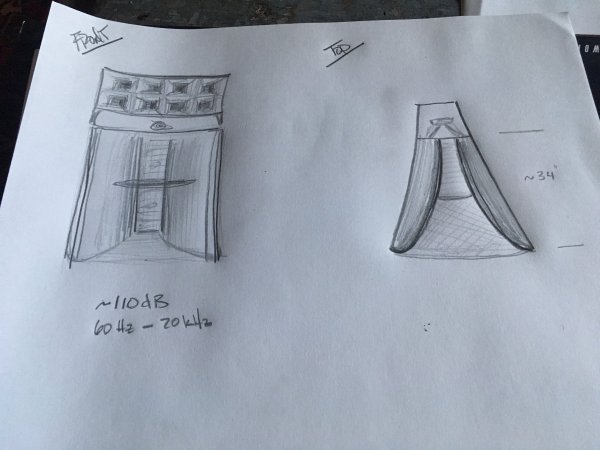

My horns system may not be giant, but it is quite big I guess. It was the optimum for what I wanted to achieve.

Yes, there are inherent problems like the distance between drivers the lobing it creates, and depth of the horns differing causing time alignment issues, horns colouring the sound etc. but they can all be solved. I know as I have solved them both measurably and aurally up to my standards, the information I have and the instruments I use to check them.

There are many things that a system like this dictates. One is space. I had to physically demolish walls and build a bigger room so that the sum of the drivers can be correctly heard. That meant I could not be too close to them while I had to be far to a back wall for acoustics purposes. The minimum distance for the exact aligned and correct distance for me was minimum 430cm away from the diaphragms. (this may be a problem for people and may even be prohibitive to have a system like this) My room is 10 meters deep, and 6meters wide for the most part, it gets wider further back.

Firstly time alignment. I have time aligned all my drivers using impulse response to my seating position, so I know and can test their alignment. There is no issue there, I can physically do this and measure it to confirm it. I have done this passively by physically aligning the drivers.

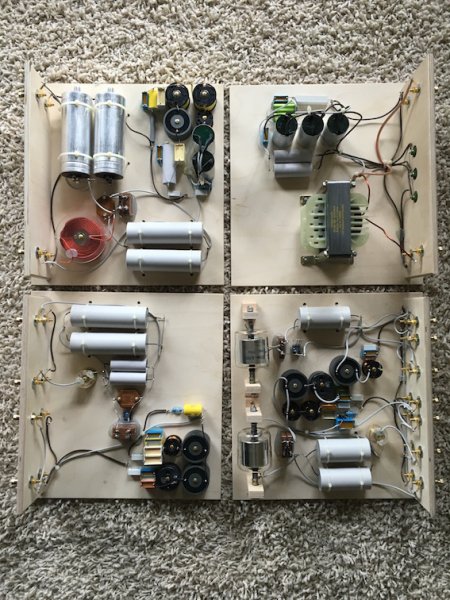

I have also used 1st order crossovers for the horn channels except for the tapped horn working below 40hz (3rd order) and the direct radiators working below 120hz (2nd order). There is a very important thing to do when using first order filters. For them to work you need to choose drivers and horns working together very very carefully and for their sums you need a flat impedance/response. It is impossible to have the ideal responses without any correction. So with the filter, I have also impedance correction on my crossovers. Otherwise a first order filter may not be (most likely) able to work against your driver/horn combination channels response deviations. It may try to filter a certain frequency while your driver/horn has a rising response there. A first order filter wont be able to do its job there unless it was flat to begin with.

Then there are certain limits to horns to sound good and physically work. One of them is, you can not push a horn below a certain limit. That lies between 1.5 to 2 times over its cutoff limit. Now, people claim to get it but what they generally do is, boost the driver there and actually get, not a horn loaded response, but a direct response from the driver. This not only also adds coloration but also distortion. The only place you can get away very close to cutoff is the midbass horn with a back chamber. Here you can reactance annul it and have a good response close to cf without audible problems.

Horns also colour the sound and "shout" when pushed too much to work wide-band. Generally a horn works for about 3 octaves and maybe a little more. You can get beyond it, byou can still measure flat but it will sound coloured and will beam. This again dictates what you can use as it dictates size and depth. That is why I could not use anything below 120hz to be horn loaded. If I had done it, I could not have aligned a horn that size both in height (the other channels would be too high, and upper end information which has narrower field would not be around my ear height) or it would not be aligned vertically which also sounds wrong to my ears and causes further phase and lobing anomalies. This dictated me that the biggest horn I could use can have a 1 meter diameter, hence my midbass. I also had different horn topologies at my place. I have found out that anything that plays above 60-80hz sound different in a bad way when the horn is folded and causes time alignment issues which can be heard. So I could not use horns and had to go with direct radiators.

All these are choices according to what is important to me to achieve what I think a good sound is. At the end, my choices dictated me my topology. 18hz to 40hz tapped horn, 40-120hz direct radiators, a 110hz cutoff tractrix with a 12" 285-2000 supravox modified with reactance annuling for 120-500hz, a 200hz tractrix with a 2" beryllium cd from 500 to 4500hz, a 1400hz JMLC horn with 1" beryllium cd for 4500-10000hz, and a fostex t500amkII for above that. These frequencies are not very exact as you can guess this is a first order system but these are the main band the channels are working.

So, for me, choosing the drivers very carefully, matching them with the right horns and using them in their intended bandwidths while having the right crossover altogether is very important. Also having a relatively flat impedance gets you a very good sound from the SET amp I use for my horns, which is great. I use solid states for my direct radiators and tapped horn.

The room is also very important, having the right homogenous decay and having a good response. I am sharing not only photos but also measurements as people tend to leave that generally. Here is my spl response and room decay (rt60). The SPL response was taken before room treatments were finished, the 70hz bump is gone and 100hz is much better but the rise towards 200hz but a little less pronounced. It is still there and can be seen to reflect in rt60 too. However as you can see, this is my room response from my listening point. It actually is +-4db for 18hz to 20hz which is for me a very good response. The decay in the room is also better than most of the studios I have been fortunate enough to be at!