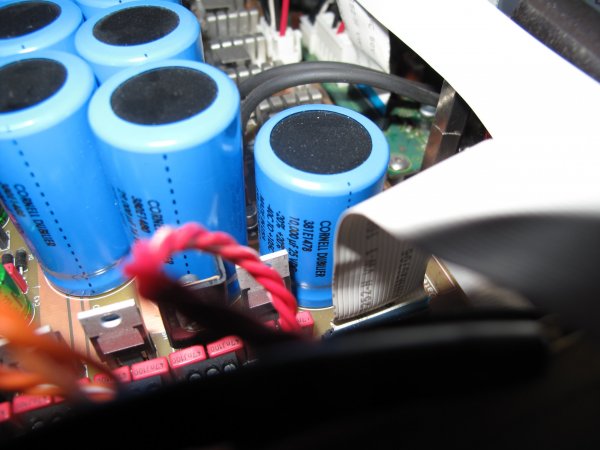

I'd be especially careful replacing anything, particularly capacitors, with different manufacturers of the same printed value without confirming the exact value with a capacitance meter. I've been where Ayreman is for most of my audio life, modifying almost anything that can be opened, in search of better sounding parts. Caps are notoriously high in variance from published values. They are surprisingly often +/- 20% even if the values suggest they are +/- 5%. But even that may not be good enough, A finely tuned circuit can sound totally different with a 5% change of value from what is being replaced. If your cap value is lower than stock, its easy to piggy back caps in parallel to increase the overall value to get the exact value of the original, but if your stock is lower in farads than your replacement, then its obviously more of a pain. Also keep in mind that ideally you don't want to change the ESR when you change cap brands. Doing this work without a basic meter is simply asking for trouble. The reasons manufacturers chose what they use is based on many things; cost, sonics, size, etc. But at the minimum, you really should match the exact measured value of the original component to be replaced and not rely on the value labeled on the case, which is a potential recipe for disaster.

If you parallel them it changes ESR by a huge amount to the circuit - which can have way more impact than value variance. And contrary to popular belief lower resistance isn’t always better (why would we have resistors if it was?).