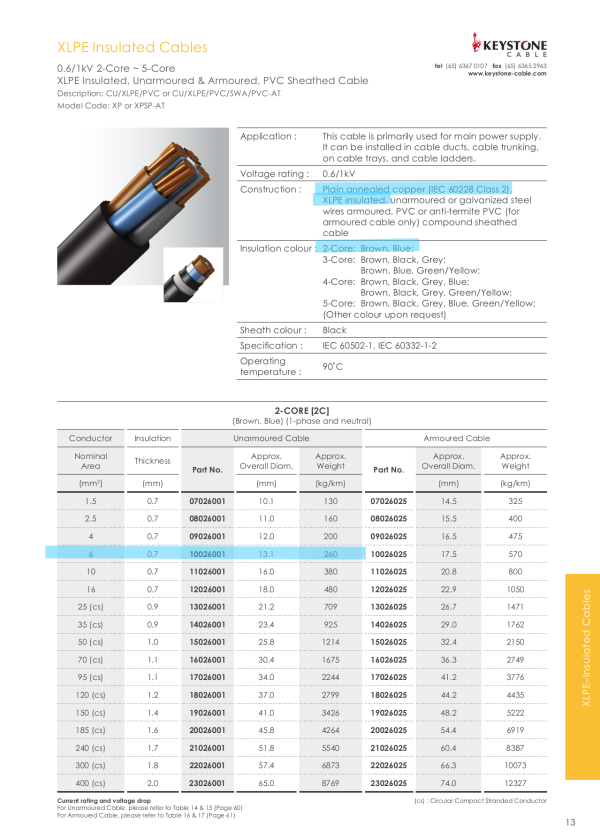

Obtained two samples of the XLPE insulated PVC sheathed cables. Note that there's an optical/perspective distortion in the photo, due to proximity differences to the iPhone's lens/sensor array. The upper bundle is supposed to be smaller than the lower bundle.

Using a bright LED headlamp and a magnifying glass to examine them closely, the XLPE insulation had a wet/transparent sheen reminiscent of Teflon.

The 6mm2 sheath (top) has the following printed: "0.6/1KV XP 2C X 6MM2 P/N <10026001> PSB LISTED TO IEC 60502 Y2021". Its rotational/twist frequency is approximately 4-5 twists per 1.0m.

The 10mm2 pair's sheath (bottom) had the following printed: The 10mm2 sheath has the following: "0.5/1KV XP 2C X 10MM2 P/N <10026001> PSB LISTED TO IEC 60502 Y2023 23022" There is a fibrous wrap around the two 10mm2 sheathed conductors which is missing on the other 6mm2 conductors; believe it's some sort of fiber cover to aid in either holding the twisted pair in place, or helping the twisted pair become sheathed properly. Its rotational/twist frequency is approximately 2-3 twists per 1.0m.

Comparing this to the alternative of twisting two "loose" conductor cables together, the positives are:

- XLPE is acknowledged to be a superior dielectric compared to PVC

- the twisted pair geometry will be predictable and constant, not prone to misbehave by "springing" out of synch

- the solid PVC sheathing is extremely tough, resisting crushing, ingress of moisture, etc.

- the solid PVC sheathing will facilitate installation, enabling the pushing and pulling through tight PVC conduit spaces

Negatives:

- rotational/twist frequencies are not as high as hand-twisting two loose/separate conductor cables together

- maximizing rotational/twist frequency is very important to maximize inductive coupling to cancel common-mode noise, including RFI/EMI

- overall, much bulkier and heavier than "naked" twisted conductor pairs

Mitigants:

- the cable manufacturer can accept a customized order, to employ an extra step during manufacturing to achieve a twist/rotational frequency of 7 twists per 1.0m

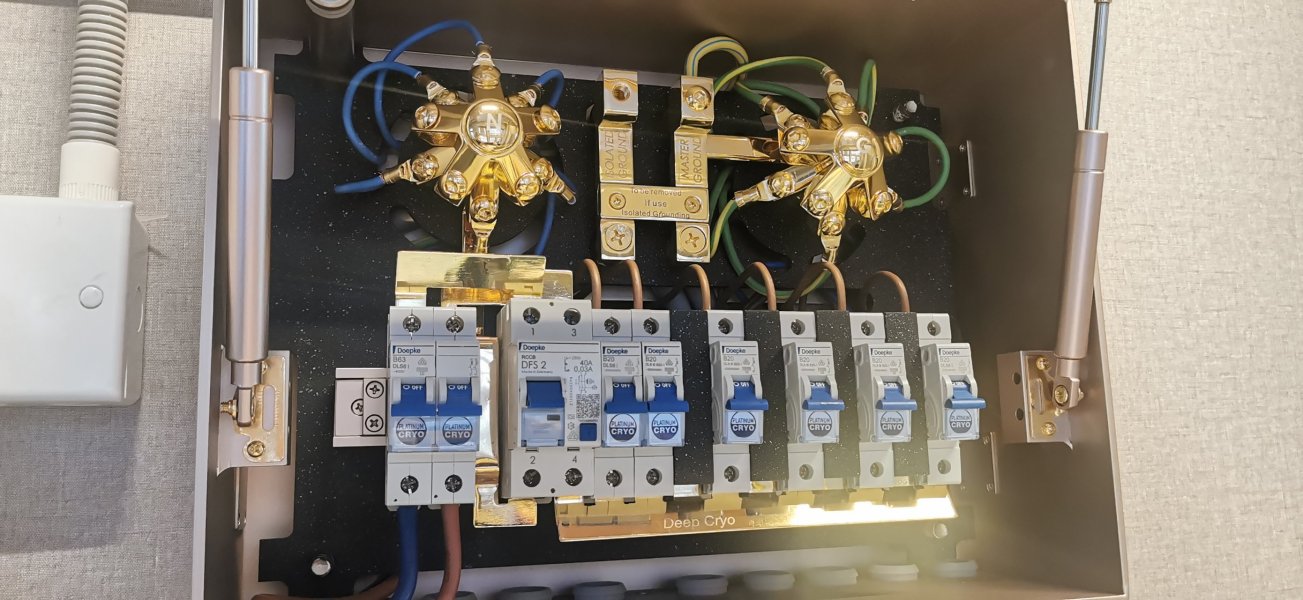

This is great news! It's very likely that I'll be going with the 2 conductor 10mm2 XLPE insulated PVC sheathed power cable for my dedicated audio room's AC wiring between the sub-MCB and the Furutech NCF AC duplex outlets.

Many have suggested using thinner (higher gauge) conductors for source components, as they (somehow) sound superior to thicker (lower gauge) conductors. Conversely, thicker (lower gauge) conductors have been reported to be superior for power amplifiers and power supplies because of their superior current delivery characteristics. Many have fallen into this conundrum of not being able to decide which is the better solution, as the two outcomes appear to be mutually exclusive.

I've decided to wire my system with thicker (lower gauge) conductors to maximize current delivery for plugging in amplifiers directly into the dedicated AC duplexes, and *hopefully* through PS Audio Power Plant AC regenerators and PLiXiR toroidal isolation transformers, bend the laws of physics to achieve the speed and delicacy of thinner (higher gauge) conductors for my source components.

Opinions/suggestions are welcome!