There are some common misconceptions of what constitutes a balanced signal, and hence, balanced cable requirements. Friedrich Schaefer addressed this years ago in his excellent manual for the ASR Basis Exclusive phono preamp. in summary, a phono cartridge is an inherently balanced device and although many tonearms only output RCA cables, a cable adapter can easily be made to take advantage of your phono stage if it is a balanced design. The essentials are here:

2.2 Connecting the tone arm cable

Moving Coil (MC) and MM cartridges can be connected to the ASR Basis Exclusive.

Balanced or unbalanced connection can be used at the inputs of the Basis Exclusive !

But we strongly recommend the use of balanced connection !

The ASR Basis Exclusive is designed for using the balanced input and has best results only with balanced input connection.

!! Cartridges are like microphones the only balanced sources from their construction !!.

With unbalanced connection at the input you don’t have the full possible sound quality.

The use of the balanced output is not obligatory together with the use of the balanced input.

Definition of a Balanced connection :

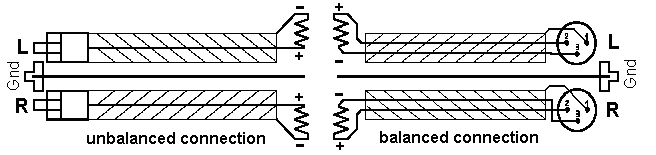

A balanced tone arm cable must have two conductors and a separate shielding.

This shielding has to connected separately to ground and should never be connected to the plus or minus wires- otherwise you will get heavy distortions, cause the shield will work as antenna !

Balanced cables can be connected at both the RCA or the XLR plug. Both inputs sockets are internally connected. The RCA inner pin is connected to Plus, the outer ring to Minus.

The pins on the XLR sockets are international standard: 1 = Ground, 2 = Plus 3 = Minus.

The only advantage of using XLR is that the third pin 1 can be used for ground connection of the shield. At RCA the shield must be connected separately to the big ground pole plug connector.

A tone arm cable that has already two wires and be converted simply by connecting the shield to ground ( the black pole plug at the Basis ) instead of to the outer ring at RCA what is minus.

Please connect the ground cable of your turntable to the (black) pole terminal on the back panel.

View attachment 75998

ASR Audio Systems Friedrich Schaefer, D- 35 745 Herborn +49 (27 72) 42 905