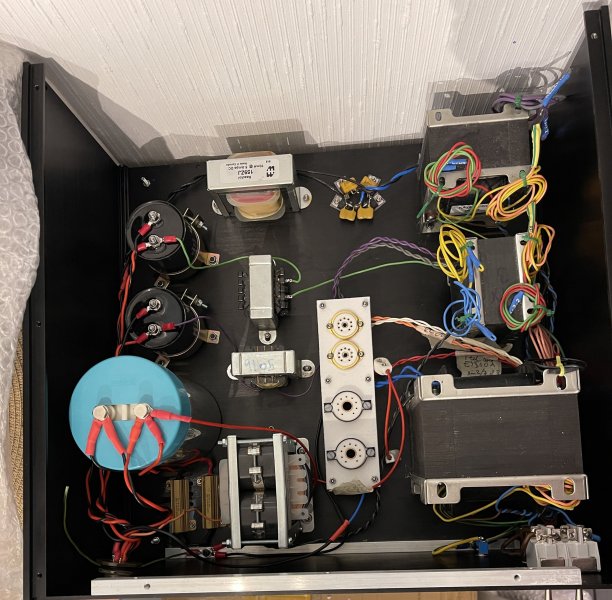

Thanks.Here is the link for the whole thread regarding upgrades on theese amps;

Kits useable with a M500 300B Monoblock amp

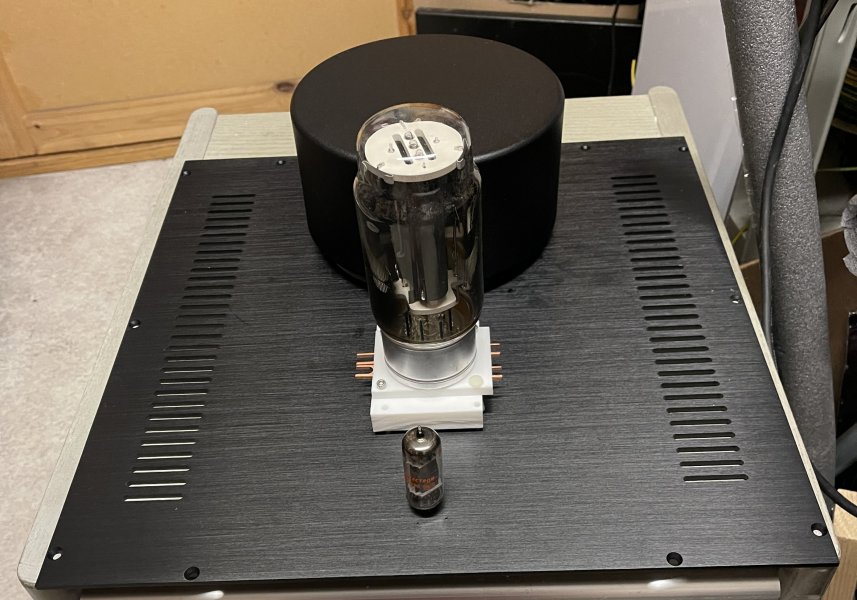

I recently got a pair of older (Early 2000's) Consonance M500 300B monoblock amps and after reading a lot of posts, many suggested that I could upgrade the amp significantly thru parts or upgrade kits from DIY. I am interested in the Power supply and ABS modules, but am not sure what if any of...www.diyaudio.com

And this is the schematics for the upgraded amp.

View attachment 116038

Its not a good idea to run the power tube without a stopping resistor. 150 Ohms will work better than 10K!

The 47 Ohm resistor should be bypassed to ground at its output else it will generate noise in the power supply. If it were me I would simply get rid of it.

The input tubes should each have a grid stopping resistor. 1.5K is adequate. You may notice a lower noise floor. Also, there should be a small resistance of 50 Ohms or so (matched) in series with each cathode of the input tubes to prevent current hogging, since they are in parallel. Otherwise distortion will be higher! You may notice greater clarity once this is corrected.

There clearly is a bit of compensation going on about the coupling cap. Did anyone explain to you what this is for? The answer to this question is important- it appears the compensation is for something, a deficiency somewhere.

I really don't think the grid choke is a good idea. Chokes are inductors and so at some low frequency they have a low impedance as well! If low frequency noise is able to pass thru the input stage, the low impedance presented will cause the voltage amplifier/driver to make additional distortion. Its hard to imagine how that's a good thing. So to use it, you'll want a low frequency filter of some sort (based on the cutoff frequency the choke and the caps present) to make sure the voltage amplifier/driver does not see any low impedances on account of this property. That filter does not appear to be the coupling cap array, which has a pretty high capacitive value!! So I'm really wondering how this is supposed to work. Usually you want to keep the coupling cap value as low as possible, so as to prevent coloration from the part itself, so long as you satisfy all your low frequency bandwidth requirements.

Our shop speaker is 16 Ohms and very easy to drive. We usually are running less than 4 Watt peaks on them, well withing the 20-25% range I've commented about in the past. Our amps have meters so we can see how much power is being made.Ralph, have you heard the original Lamm ML2 with an easier speaker load say, 16 ohms and 105dB? I ask because I have read your posts which suggest such SET amplifiers sound best when using less than 10% of their power rating for lowest distortion.