@DasguteOhr You have said you are trained as an electrician yet I sense you have worked as a diplomat as well

Visit to Audiophile Bill to hear his horns project

- Thread starter spiritofmusic

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

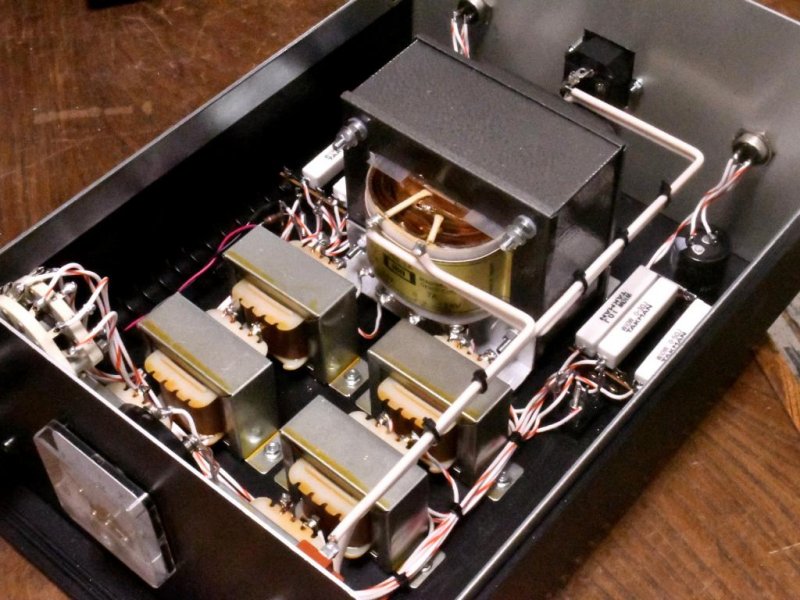

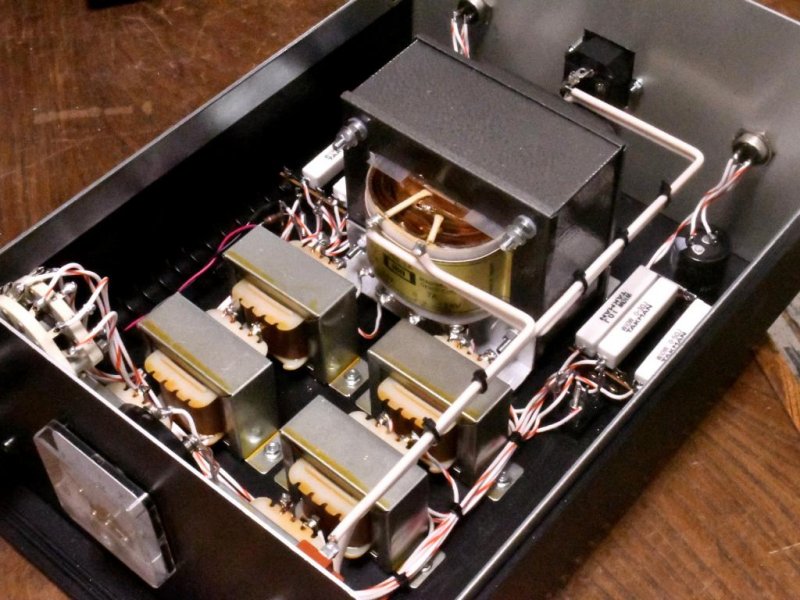

Guys, let's talk about field coil Power Supplies - I just switched from constant voltage lab supplies (which I've been using for years), to unregulated (for the high voltage midrange) and constant current (for the low voltage upper bass woofers) from Wolf Von Langa.

Wow!! I’m really surprised at how much of an improvement the new power supply has made!

The difference is much more profound than I expected. Vocals sound more relaxed and less strained than I’m used to. When I decided to upgrade from my Lambda constant voltage lab supplies, I was doing it mainly to eliminate noisy transformers and for aesthetics. I had learned that constant voltage supplies are not recommended for field coil speakers; but I had no idea the difference would be so profound - it’s as if I upgraded the entire speakers. Imaging is also more focused, especially at different frequencies. For example, a guitarist who sings is now centered; previously, the guitar notes would be slightly un-centered relative to her voice.

Bottom line: if you are using constant voltage supplies, you are missing out!

This one powers all 4 drivers: 2x Midrange (110V) and 2x Upper Bass (12V)

View attachment 86329

Congratulations; WVL power supplies are exceptional quality.

No. definitely i have my corners and edges@DasguteOhr You have said you are trained as an electrician yet I sense you have worked as a diplomat as well

No. definitely i have my corners and edges, but i can understand if someone doesn't like certain products or has had bad experiences. fortunately there is a wide range so everyone can be happy

Right. But not that many options, actually... especially for high voltage field coil supplies. But I understand it's a tiny niche market.

ask here, they have a lot of things when it comes to field coils, mostly vintage which is not the worst choice.Right. But not that many options, actually... especially for high voltage field coil supplies. But I understand it's a tiny niche market.

Sachsenwerk field coil speaker

www.monodyn.com

P.S

you need 110 volts most telefunken and klangfilm drivers works at this voltage. search for fieldcoils from this company

Last edited:

Very interesting! Thanks.ask here, they have a lot of things when it comes to field coils, mostly vintage which is not the worst choice.

Sachsenwerk field coil speaker

www.monodyn.com

By the way, I am selling these brand new vacuum tube power supplies. Adjustable DC output from 6-12V and 100-115V for each chassis. If anyone is interested, let me know. I also have spare tubes.

Note that these are mercury tubes, so you will have to be careful when using these supplies.

Hi All,

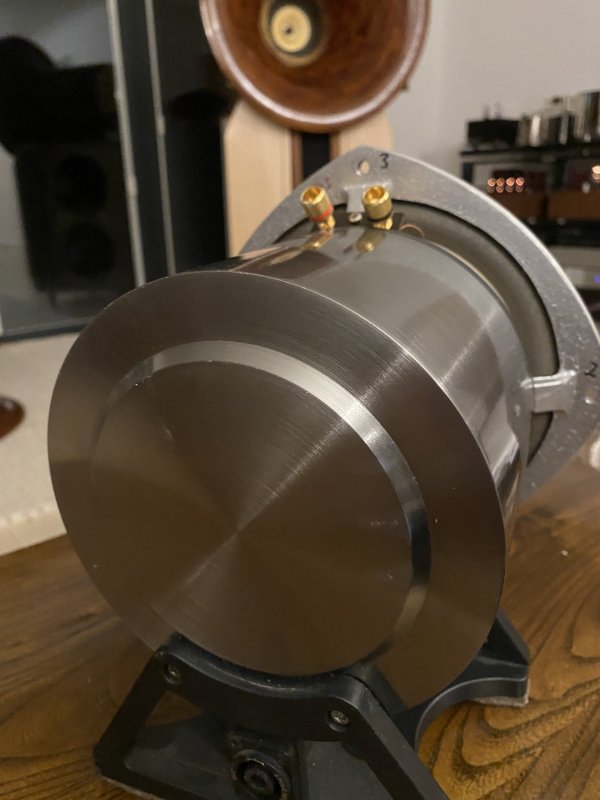

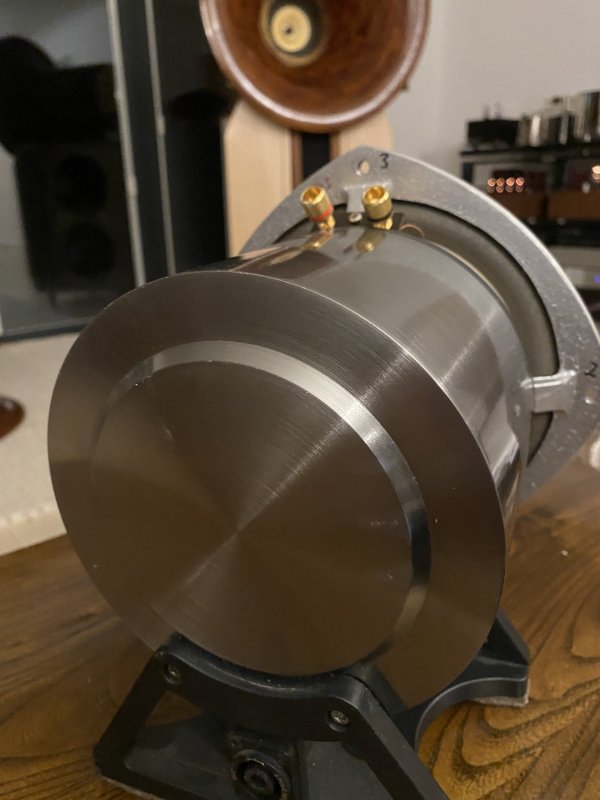

After a good deal of hibernation from building, I have a few projects that I have fired up again as desperate to see them in action. The first major one is the move from permanent neodymium motors on the AERs to the monster field coils.

I have started that process last night. One thing I waiting for before some immediate process is some m5 double ended studs and nuts. For those of you accustomed to aligning Lowthers or other full range drivers, you’ll know the curse and pain of the dreaded thin spanner hassle. The double ended studs drastically reduce that misery - one end will go into the field coil face plate and semi permanently fixed with a drop of thread lock. The other end can then easily go into the holes on the frame and locked in place by washer and nuts. Anyway - they arrive tomorrow.

I still only have my lab power supply for initial testing - it is no good because it has a noisy fan that comes on so not ideal! That said it does interestingly offer me variable voltage but with options for constant voltage OR constant current settings. This I found interesting based on Surge’s comments on constant current being preferred. I will be able to test both with the supply so that is helpful.

My next issue is the motor needs me to carve some slots into the rear horn chamber as to take the weight of the motor itself and to avoid shearing forces against the frame bolted to the horn throat.

After a good deal of hibernation from building, I have a few projects that I have fired up again as desperate to see them in action. The first major one is the move from permanent neodymium motors on the AERs to the monster field coils.

I have started that process last night. One thing I waiting for before some immediate process is some m5 double ended studs and nuts. For those of you accustomed to aligning Lowthers or other full range drivers, you’ll know the curse and pain of the dreaded thin spanner hassle. The double ended studs drastically reduce that misery - one end will go into the field coil face plate and semi permanently fixed with a drop of thread lock. The other end can then easily go into the holes on the frame and locked in place by washer and nuts. Anyway - they arrive tomorrow.

I still only have my lab power supply for initial testing - it is no good because it has a noisy fan that comes on so not ideal! That said it does interestingly offer me variable voltage but with options for constant voltage OR constant current settings. This I found interesting based on Surge’s comments on constant current being preferred. I will be able to test both with the supply so that is helpful.

My next issue is the motor needs me to carve some slots into the rear horn chamber as to take the weight of the motor itself and to avoid shearing forces against the frame bolted to the horn throat.

So I have been doing some alignment of the AER frame. One thing that is super interesting about these field coil motors - that gap is slightly larger in diameter meaning it is much easier to align the drivers without the dreaded “Lowther” scrape. This doesn’t impact the inductance per se since the motor was designed / specified for such a gap. Most interesting is the depth of gap, which is over double that of a standard gap of 4mm. This allows more xmax that manifests as better bass performance in the measured data - will need to confirm in due course.

In order to optimise the depth into the gap, my friend Lee (also on wbf) is very kindly making me a pair of steel gaskets - this will offset the frame of the AER from the field coil face plate by 3mm. I might experiment with a sorbothane type decoupling also,

let’s see.

One final piece of info - the permendur pole on my field coil included a removable bolt within a bolt to allow me to use phase plugs of my choice / design. I can comfortably say that a phase plug is very much needed with the AER in a large front loaded horn like I designed here. I will be building various phase plugs in different materials to see what works best. I fancy a long Lignum Vitae one lol.

In order to optimise the depth into the gap, my friend Lee (also on wbf) is very kindly making me a pair of steel gaskets - this will offset the frame of the AER from the field coil face plate by 3mm. I might experiment with a sorbothane type decoupling also,

let’s see.

One final piece of info - the permendur pole on my field coil included a removable bolt within a bolt to allow me to use phase plugs of my choice / design. I can comfortably say that a phase plug is very much needed with the AER in a large front loaded horn like I designed here. I will be building various phase plugs in different materials to see what works best. I fancy a long Lignum Vitae one lol.

Looking forward to the upcoming reports. Good luck with all the mods Bill.

Looking good, Bill!

It sounds like you are using a lab-style power supply which I used for many years. Note that they are not really constant current. They usually are constant to a point, but then switch to constant voltage when a preset threshold is reached.

I found that switching to an unregulated voltage, true constant current supply (from WVL) - “unfortunately” - made a very noticeable improvement to the sound.

Keep us posted..!

It sounds like you are using a lab-style power supply which I used for many years. Note that they are not really constant current. They usually are constant to a point, but then switch to constant voltage when a preset threshold is reached.

I found that switching to an unregulated voltage, true constant current supply (from WVL) - “unfortunately” - made a very noticeable improvement to the sound.

Keep us posted..!

Looking good, Bill!

It sounds like you are using a lab-style power supply which I used for many years. Note that they are not really constant current. They usually are constant to a point, but then switch to constant voltage when a preset threshold is reached.

I found that switching to an unregulated voltage, true constant current supply (from WVL) - “unfortunately” - made a very noticeable improvement to the sound.

Keep us posted..!

Hi Surge,

Yes I remember clearly - it is front my mind. I have a lot to learn here tbh.

Okay so I acquired the stainless steel double ended m5 studs, washers, and low profile nuts. I also made a lead infused rubber gasket to mate with the steel gaskets that my friend, Lee, has made.

Below you can see the stud assembly. I am sure this is of little interest to you normal folks, but those of you into full rangers, this has potential to be a much easier solution - let’s see.

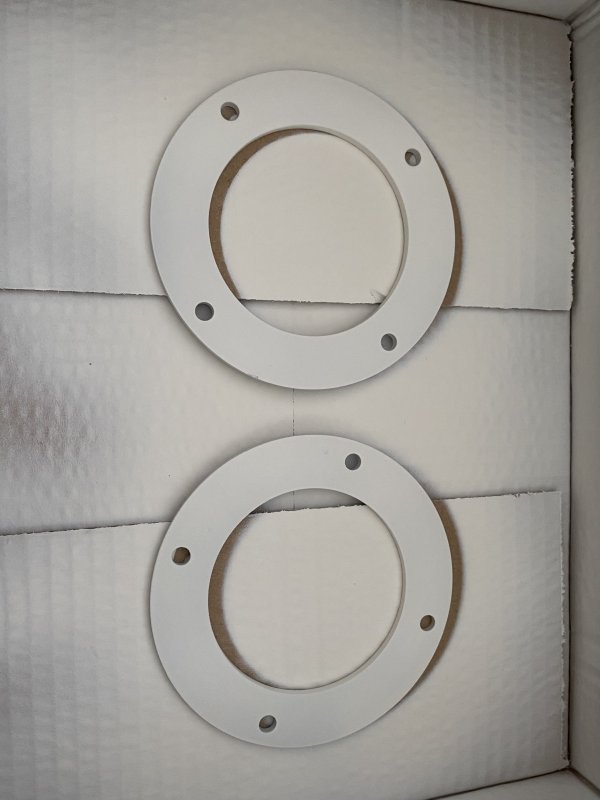

Lee has kindly made the gaskets in mild steel so I will need to gently abrade the surface after a quick acetone clean. Then I will apply primer and spray them black for a nice cosmetic finish. Here are the raw steel gaskets:

I have also made contact with Ken, a Japanese engineer, and he is building me a field coil supply to get me started. Will be adjustable between 8-14 volts so covers all bases for me. I expect I will likely go down the full crazy Tungar direction in due course but for now I am sticking solid state. Ken can build all manner of the crazier big bottle and Tungar type supplies - just a case of budget more than anything else. Anyway, here is a photo of the power supply I am getting below:

So really the ball in now in my court with wood carving!

Below you can see the stud assembly. I am sure this is of little interest to you normal folks, but those of you into full rangers, this has potential to be a much easier solution - let’s see.

Lee has kindly made the gaskets in mild steel so I will need to gently abrade the surface after a quick acetone clean. Then I will apply primer and spray them black for a nice cosmetic finish. Here are the raw steel gaskets:

I have also made contact with Ken, a Japanese engineer, and he is building me a field coil supply to get me started. Will be adjustable between 8-14 volts so covers all bases for me. I expect I will likely go down the full crazy Tungar direction in due course but for now I am sticking solid state. Ken can build all manner of the crazier big bottle and Tungar type supplies - just a case of budget more than anything else. Anyway, here is a photo of the power supply I am getting below:

So really the ball in now in my court with wood carving!

Bill, us mere mortals out here are getting much vicarious pleasure from your exploits. Keep it going, this is fantastic stuff.

How does it feel to be on the cusp of a potentially unique class leading design and implementation?

How does it feel to be on the cusp of a potentially unique class leading design and implementation?

Bill, us mere mortals out here are getting much vicarious pleasure from your exploits. Keep it going, this is fantastic stuff.

How does it feel to be on the cusp of a potentially unique class leading design and implementation?

Marc - thank you for your kind words. It is the kindred spirit of yourself and others here that energises me to keep trying to push the envelope

Haha, but we're not paying a penny of admission to your House Of Dreams lol

For those interested in what is occurring on the mad analogue front see the DaVa thread: https://www.whatsbestforum.com/threads/dava-fc-a1-a-field-coil-contender.30720/post-790763

Big shout out to Lee from WBF - top man. Built me the steel gaskets on his CNC door to door in 2 days! Thank you very much, Lee.

Here is the constrained layer construction in situ. As a recap in terms of what all this is about. The AER frame must be attached to the field coil motor. But voicecoil depth in the gap is very important to allow for optimal magnetics and driver xmax. Too high, and the voicecoil could come too far out of the gap - in this instance the force acting on the coil begins to fall and the movement slows down, that is, a smooth limitation and increase in distortion - third harmonic. If the voicecoil would be too low in the gap then you either bottom the cone out on the bottom of the gap itself which can damage the driver and obviously sound terrible.

Long story short - it is crucial to measure the depth of your chosen driver voic and H which is the height above that before the cone flares out. You then need to know the depth of your gap and do some basic math to work out where would be optimal.

As I mentioned previously this field coil motor has double the Maxwell rating of a Lowther motor and 38% more than my existing AER motor. Maxwells are calculated as:

B*S, there S is an area of gap

S is a Height of gap* 2pi*Diameter (this is in cm)

B is measured in Gauss and in layman’s represents the strength of the magnet.

The constrained layers are my attempt at reducing any resonance between the frame and the motor. To achieve this I have constrained steel gasket and lead infused hard rubber gasket coupled to the aluminium frame and the iron and permendur of the motor.

Here is the constrained layer construction in situ. As a recap in terms of what all this is about. The AER frame must be attached to the field coil motor. But voicecoil depth in the gap is very important to allow for optimal magnetics and driver xmax. Too high, and the voicecoil could come too far out of the gap - in this instance the force acting on the coil begins to fall and the movement slows down, that is, a smooth limitation and increase in distortion - third harmonic. If the voicecoil would be too low in the gap then you either bottom the cone out on the bottom of the gap itself which can damage the driver and obviously sound terrible.

Long story short - it is crucial to measure the depth of your chosen driver voic and H which is the height above that before the cone flares out. You then need to know the depth of your gap and do some basic math to work out where would be optimal.

As I mentioned previously this field coil motor has double the Maxwell rating of a Lowther motor and 38% more than my existing AER motor. Maxwells are calculated as:

B*S, there S is an area of gap

S is a Height of gap* 2pi*Diameter (this is in cm)

B is measured in Gauss and in layman’s represents the strength of the magnet.

The constrained layers are my attempt at reducing any resonance between the frame and the motor. To achieve this I have constrained steel gasket and lead infused hard rubber gasket coupled to the aluminium frame and the iron and permendur of the motor.

Attachments

Glad that the plates worked out for you Bill, looks good mate and more than happy to helpBig shout out to Lee from WBF - top man. Built me the steel gaskets on his CNC door to door in 2 days! Thank you very much, Lee.

Here is the constrained layer construction in situ. As a recap in terms of what all this is about. The AER frame must be attached to the field coil motor. But voicecoil depth in the gap is very important to allow for optimal magnetics and driver xmax. Too high, and the voicecoil could come too far out of the gap - in this instance the force acting on the coil begins to fall and the movement slows down, that is, a smooth limitation and increase in distortion - third harmonic. If the voicecoil would be too low in the gap then you either bottom the cone out on the bottom of the gap itself which can damage the driver and obviously sound terrible.

Long story short - it is crucial to measure the depth of your chosen driver voic and H which is the height above that before the cone flares out. You then need to know the depth of your gap and do some basic math to work out where would be optimal.

As I mentioned previously this field coil motor has double the Maxwell rating of a Lowther motor and 38% more than my existing AER motor. Maxwells are calculated as:

B*S, there S is an area of gap

S is a Height of gap* 2pi*Diameter (this is in cm)

B is measured in Gauss and in layman’s represents the strength of the magnet.

The constrained layers are my attempt at reducing any resonance between the frame and the motor. To achieve this I have constrained steel gasket and lead infused hard rubber gasket coupled to the aluminium frame and the iron and permendur of the motor.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 2

- Views

- 609

- Replies

- 3

- Views

- 738

- Replies

- 11

- Views

- 2K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |