Yes. Vibration that gives pleasure. I am blessed.Maybe the vibration from the subs creates some kind of natural vibes through the ML3s

Visit to Audiophile Bill to hear his horns project

- Thread starter spiritofmusic

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Love it Bill, beautiful grain and great shape. Just not sure where the compression driver will goSorry no speaker updates other than I have finished the horn sub plans and awaiting materials (timber). Hopefully a few days before I can start.

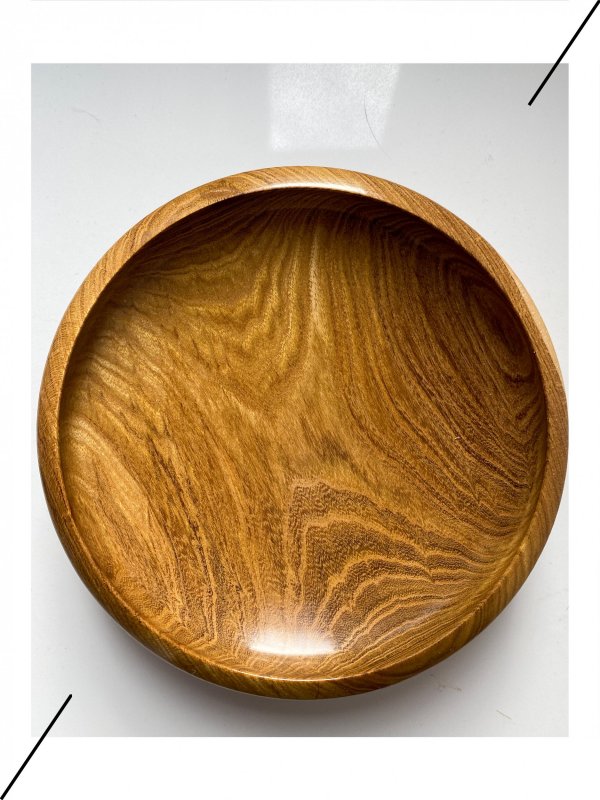

In the meantime, I turned a piece of Laburnum out of my father in laws garden. Here we go for timber lovers:

View attachment 96108

Love it Bill, beautiful grain and great shape. Just not sure where the compression driver will go

Hehe - will just have to cut a hole in the middle lol. Thanks, Graham.

Might be asking too much, would you care to share any pics of the workspace / lathe ?

Sure will send a picture of my lathe tomorrow or next day unless I locate one on my phone now.

I use a Powermatic 4224b with full bed extension. 900lbs without bed extension. I think total must be 1350lbs and 3HP.

I have quite a lot of other industrial level machinery and too many hand tools. Speak to any wood worker and they’ll tell you the same - tools are an addiction.

I have quite a lot of other industrial level machinery and too many hand tools. Speak to any wood worker and they’ll tell you the same - tools are an addiction.

There's no such thing Bill!...I have quite a lot of other industrial level machinery and too many hand tools.

david

Last edited:

Never enough tools ever. lol.There's such thing Bill!

david

That can depend on what the topic is in a thread…Never enough tools ever. lol.

Apologies for a slight hiatus this end. I received all my timber (at last) to build the big sub horns. In my sims they are still 101dB at 22hz so are likely going to be good fun lol. Yesterday I have been ripping all the sheets down into the different parts. This is an important part of the build because accuracy is paramount. Even 1/2mm out will cause headaches. I use a cast iron table saw from the 1960s - still extremely accurate and an absolute pleasure to use. Wouldn’t change it. Below you’ll see the cut panels - this is 26mm extremely premium beech rotary plywood with every layer solid beech. As a consequence it is extremely strong, very dimensionally stable, and heavy. You will see below a picture

of the cut panels.

In my build, I will use a contrasting timber on the front baffle just to break up all the beech and create some design interest. I am trying to determine what to go for now. I am veering in 2 directions - 1 would be walnut and the other maple. Any thoughts your end?

I was over at the timber yard, and like any timber lover, it is a dangerous place for the wallet - kid in a sweet shop type of thing. Anyway I spotted this whacking great single piece chunk of kiln dried iroko in 80mm thickness. Brought it home and made a very large and heavy turntable plinth - didn’t intend to get derailed by this but couldn’t resist lol. I am just finishing the French polishing now. The maple side cheeks were a pain because they were hand carved. It is hard to get perspective on this one because the plinth has huge bevel cuts underneath to make the plinth look like it is floating. In the 2nd picture you can see the bevels and m8 spikes. These can be replaced with any footer of course. Iroko is an exceptionally strong timber and very dense. It is often used now in the boat world as teak substitute. Great resistance to rot or damage. Tonally it is rich and full sounding

Back to subs. All the joinery is being mapped out now. Quite complex as it uses no screws and nails. Combinations of dados, rabbets, slots, tenons / mortise.

of the cut panels.

In my build, I will use a contrasting timber on the front baffle just to break up all the beech and create some design interest. I am trying to determine what to go for now. I am veering in 2 directions - 1 would be walnut and the other maple. Any thoughts your end?

I was over at the timber yard, and like any timber lover, it is a dangerous place for the wallet - kid in a sweet shop type of thing. Anyway I spotted this whacking great single piece chunk of kiln dried iroko in 80mm thickness. Brought it home and made a very large and heavy turntable plinth - didn’t intend to get derailed by this but couldn’t resist lol. I am just finishing the French polishing now. The maple side cheeks were a pain because they were hand carved. It is hard to get perspective on this one because the plinth has huge bevel cuts underneath to make the plinth look like it is floating. In the 2nd picture you can see the bevels and m8 spikes. These can be replaced with any footer of course. Iroko is an exceptionally strong timber and very dense. It is often used now in the boat world as teak substitute. Great resistance to rot or damage. Tonally it is rich and full sounding

Back to subs. All the joinery is being mapped out now. Quite complex as it uses no screws and nails. Combinations of dados, rabbets, slots, tenons / mortise.

Omg Bill that is a lovely slab of iroko… bring on those subs. It’s so beautiful to have that level of materiality!

Last edited:

Bill, do your m8 spikes screw directly into the timber or are you using female m8 threaded inserts ?

Which drivers are you going for in the subs?Apologies for a slight hiatus this end. I received all my timber (at last) to build the big sub horns. In my sims they are still 101dB at 22hz so are likely going to be good fun lol. Yesterday I have been ripping all the sheets down into the different parts. This is an important part of the build because accuracy is paramount. Even 1/2mm out will cause headaches. I use a cast iron table saw from the 1960s - still extremely accurate and an absolute pleasure to use. Wouldn’t change it. Below you’ll see the cut panels - this is 26mm extremely premium beech rotary plywood with every layer solid beech. As a consequence it is extremely strong, very dimensionally stable, and heavy. You will see below a picture

of the cut panels.

View attachment 97538

In my build, I will use a contrasting timber on the front baffle just to break up all the beech and create some design interest. I am trying to determine what to go for now. I am veering in 2 directions - 1 would be walnut and the other maple. Any thoughts your end?

I was over at the timber yard, and like any timber lover, it is a dangerous place for the wallet - kid in a sweet shop type of thing. Anyway I spotted this whacking great single piece chunk of kiln dried iroko in 80mm thickness. Brought it home and made a very large and heavy turntable plinth - didn’t intend to get derailed by this but couldn’t resist lol. I am just finishing the French polishing now. The maple side cheeks were a pain because they were hand carved. It is hard to get perspective on this one because the plinth has huge bevel cuts underneath to make the plinth look like it is floating. In the 2nd picture you can see the bevels and m8 spikes. These can be replaced with any footer of course. Iroko is an exceptionally strong timber and very dense. It is often used now in the boat world as teak substitute. Great resistance to rot or damage. Tonally it is rich and full sounding

View attachment 97539

View attachment 97540

Back to subs. All the joinery is being mapped out now. Quite complex as it uses no screws and nails. Combinations of dados, rabbets, slots, tenons / mortise.

david

Bill, do your m8 spikes screw directly into the timber or are you using female m8 threaded inserts ?

Morning Roger. Threaded inserts for full flexibility.

Which drivers are you going for in the subs?

david

I am creating a front baffle plate that will allow one to rotate any 12” driver. I am using the Supravox because I know and like its character, it blends well with the main channel AER, is 100dB before horn loading, and measures really well. I modelled all manner of drivers but landed on this one for now.

Does mahogany go with beech… that added warmth maybe.Apologies for a slight hiatus this end. I received all my timber (at last) to build the big sub horns. In my sims they are still 101dB at 22hz so are likely going to be good fun lol. Yesterday I have been ripping all the sheets down into the different parts. This is an important part of the build because accuracy is paramount. Even 1/2mm out will cause headaches. I use a cast iron table saw from the 1960s - still extremely accurate and an absolute pleasure to use. Wouldn’t change it. Below you’ll see the cut panels - this is 26mm extremely premium beech rotary plywood with every layer solid beech. As a consequence it is extremely strong, very dimensionally stable, and heavy. You will see below a picture

of the cut panels.

View attachment 97538

In my build, I will use a contrasting timber on the front baffle just to break up all the beech and create some design interest. I am trying to determine what to go for now. I am veering in 2 directions - 1 would be walnut and the other maple. Any thoughts your end?

I was over at the timber yard, and like any timber lover, it is a dangerous place for the wallet - kid in a sweet shop type of thing. Anyway I spotted this whacking great single piece chunk of kiln dried iroko in 80mm thickness. Brought it home and made a very large and heavy turntable plinth - didn’t intend to get derailed by this but couldn’t resist lol. I am just finishing the French polishing now. The maple side cheeks were a pain because they were hand carved. It is hard to get perspective on this one because the plinth has huge bevel cuts underneath to make the plinth look like it is floating. In the 2nd picture you can see the bevels and m8 spikes. These can be replaced with any footer of course. Iroko is an exceptionally strong timber and very dense. It is often used now in the boat world as teak substitute. Great resistance to rot or damage. Tonally it is rich and full sounding

View attachment 97539

View attachment 97540

Back to subs. All the joinery is being mapped out now. Quite complex as it uses no screws and nails. Combinations of dados, rabbets, slots, tenons / mortise.

Nice , I am contemplating this very same approach with the new rack.View attachment 97541

Excuse the saw dust in the top of the insert lol. I also countersink the insert so that it sits 1/2 mm below the surface. This gives a much nicer look but also allows your chosen footer to disappear from a horizontal perspective.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 2

- Views

- 610

- Replies

- 3

- Views

- 741

- Replies

- 11

- Views

- 2K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |