I am saddened that you are nervous, but my words were a response to what you wrote in reply; if the manufacturer had used, as you loudly claimed, tin for that plinth or plastic everything would have liquefied, ergo you don't know what you were talking about in reference to my post!

Conversely if you are talking in general... please don't quote me...

unfortunately that's not a 6336 but you came close.

Dissanayake has a huge stock of valves, so rest assured that no one is without tubes... Anyway, 6336s are not that rare, the problem is knowing how to use them...

you are an Industry Expert, i would like to know what you build and what is your brand? i have no other feelings but simple curiosity

You are mistaken, I'm not nervous at all. And I know when I'm being gaslighted. You happen to be talking to someone with decades of experience with high power triodes with low plate resistance and high transconductance.

There are variants of the 6336 which are even more rare! If I 'came close' my point is made.

We've had an internal design rule we call the Twenty Year Rule, which basically says that the equipment's reliability issues should be defined by electrolytic capacitor life, some of which might fail after 20 years. To that end, everything else in the product must be rated to last long beyond that (so we use military derating rules) so the product will require no service other than tube replacement. When designing with tubes, this means the tube should be in production since finding an out of production tube that was also not in production 20 years earlier is going to be a lot harder.

6336s and their brethren have been out of production since sometime in the 1970s. Actually building a commercial product based on a tube that long gone is saddling the customer with a problem.

Having been in business as long as we have, this design rule has served us very well. We've seen plenty of competitors go out of business or drop the product when they could no longer find the tubes, leaving the customer in the lurch with no support.

unfortunately you continue to write inaccuracies, you cannot replace a 6336 with two 6AS7Gs because even if electrically it can be done but at the level of sonic performance it would be a disaster! you are very superficial in your statements, the tubes have been checked at the microscopic level and have profound differences that affect the final listening performance! the 6336 have a graphite anode, while the more modest 6AS7Gs are made of metal like the 6080, you cannot use two 6AS7Gs in place of the 6336!!! In addition, always for the 6336 not all brands sound the same, there is a special one (FSE-FF) that has the graphite anode formed by several pieces glued together compared to the normal production with the anode in a single piece of graphite, this peculiarity heavily affects the final performance!

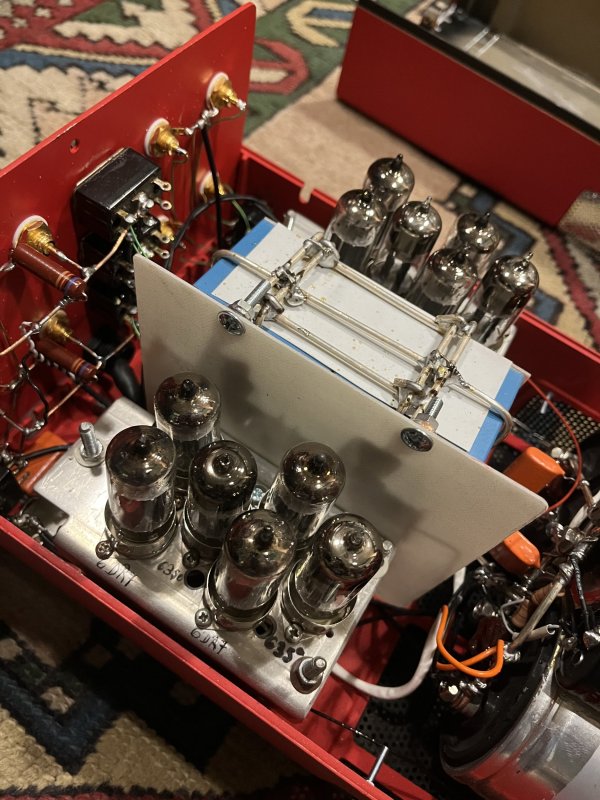

But the most interesting thing is that this preamplifier does not use the 6336, but another double triode with extraordinarily high performance and a gold grid...

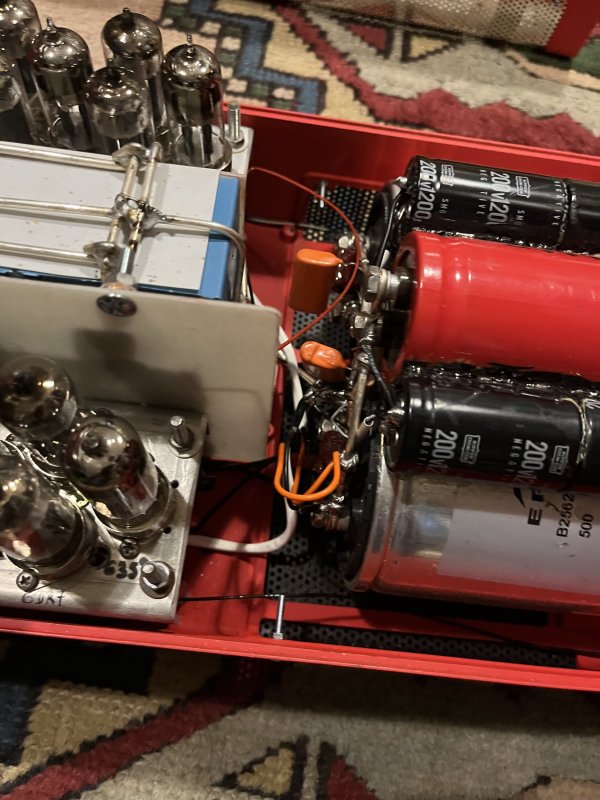

We studied the use of 6336s long ago (Atma-Sphere has been in business over 47 years) and yes, they most certainly can be replaced by dual 6AS7s with no sonic downside whatsoever and with far greater reliability. We built prototypes using that tube as the idea of a powerful OTL using only 4 power tubes per channel was highly attractive. We also built prototypes using the 7241 and production amps using the 6C33. Most of our OTLs use the 6AS7G since we could get the same power by simply doubling the number of tubes at less than 1/8th the cost of the 6336 including the extra sockets (which didn't have to be ceramic) and the labor to assemble point-to-point by hand. We actually use a 6AS7G variant made in Russia (6H13C) or China (6N13PJ) which are plentiful and thus easy for the customer to replace. 6336s and their variants are rare and expensive if you can even find them.

One of the problems we encountered with the 6336 is if it fails, one failure mode was a hard internal short. When this happens the tube can pass a surprising amount of current! This would have required a fuse for each tube section! 6AS7s by contrast usually blow out links in the base of the tube, offering much greater protection. We tried to solve this with a protection relay for the 6336; a failure promptly welded the relay contacts- so much for that idea...

So given the cost of the tube, the requirement for a good quality ceramic socket (non-Chinese, since Chinese sockets often have less reliable silver plated contacts), extra heat considerations and what happens if the tube fails, we stayed with the 6AS7s which are far less problematic in all regards. Back in the 1970s and 80s, OTLs had a bad reputation for reliability so we were keenly aware that we had to make an amp that was as reliable as possible and 6336s would have been a seriously Bad Move. It took 15 years to convince the industry that we had created the world's first really reliable OTL. Part of that is when a tube fails, it doesn't mean the amp has to be shipped anywhere; just replace the tube and possibly a fuse. If we had stuck with 6336s we'd have gone decades ago.

Please stop gaslighting me.