If the T1 TT is not accurately measuring the platter speed (ideally at 33 1/3 rpm assuming the records being played have also been cut at this precise speed....(another topic for discussion), then adding / bolting on motors with very expensive and accurate speed monitoring and operation becomes in a way academic ! If this is the case with the T1 then for me it is a flawed design, no matter how accurate the platter motor itself is at spinning at a constant 33 1/3rpm !

For such an expensive turntable with such a relatively high technology in operating platter motor speed, Esoteric should also have included a relatively high technology and possibly brand new method in directly measuring the actual platter speed for their T1 (as Grand Prix Audio have done on their TTs !) even if it meant the price of the TT going up say another US$20k for one if not the most important parameter for a TT to produce. Esoteric could have also introduced new technology in accurately measuring and monitoring the actual TT platter speed with a patent for this (as they did for their magnetic platter motor drive system).

Also using magnets for the platter drive system as the T1 does, may also possibly have an influence on the sound with the possibility that the cartridge may be picking up magnetic waves / electromagnetic forces being emitted from the T1's platter & motor drive system with a proportion that could be projecting towards the cartridge ?

As for changing the distance between the motor and the platter, maybe Esoteric included this feature to 'dial in' the platter speed to run exactly at 33 1/3 rpm (assuming one has the right and calibrated tools & instruments to also measure the platter speed to this very high accuracy). Of course changing the platter speed ever so slightly will change the sound to some degree or another.

Just my 2 pennies worth of thoughts on what at face value by looks alone is a lovely looking turntable !

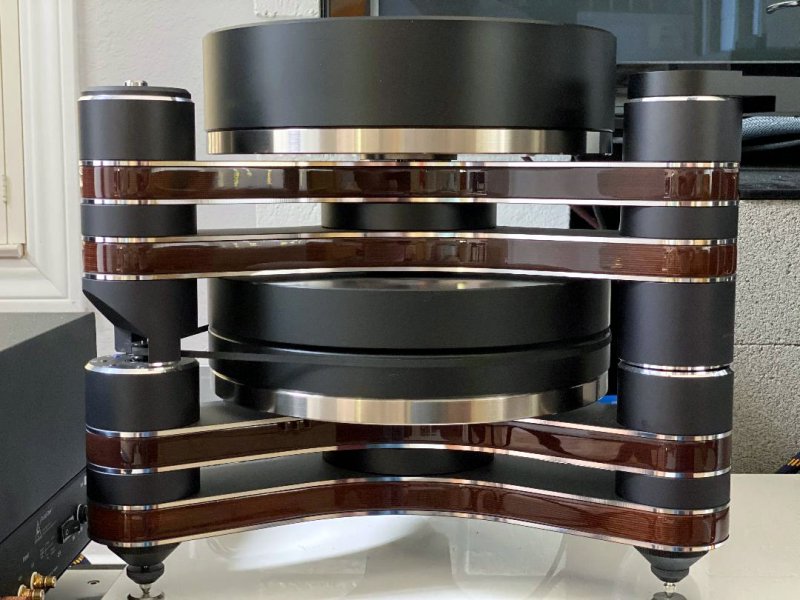

There are several interesting technologies in the T1. We've talked about the magnetic induction drive mechanism and its ability to influence the torque of the platter. This physical connection-less approach appears to be quite novel. For now I'm thinking this is not a speed control mechanism. What @mtemur and I are discussing/speculating are possibilities about how stable rotational accuracy could be achieved.

Two critical functions of a TT are to i) spin the platter at 33-1/3rpm and ii) do so with the least possible noise. I see the magnetic drive coupled with the magnetic assist to substantially but not totally float the platter (what they call 'magne-float') as primarily for noise reduction. (Maybe Mike will put a stethoscope on the plinth -- I bet it is *very* quiet.) I speculate this may influence the overall sound moreso than changing the torque of the platter. Esoteric has freedom from vibration first on their feature list. Hard to gauge relative benefit. It's an integrated design whose parts work together.

I'll go with Esoteric knowing what they are doing and the design is not flawed. It will be interesting to know the influence of the external clock.