Fireplace acoustic absorber for enhancement of the center stage

Project:

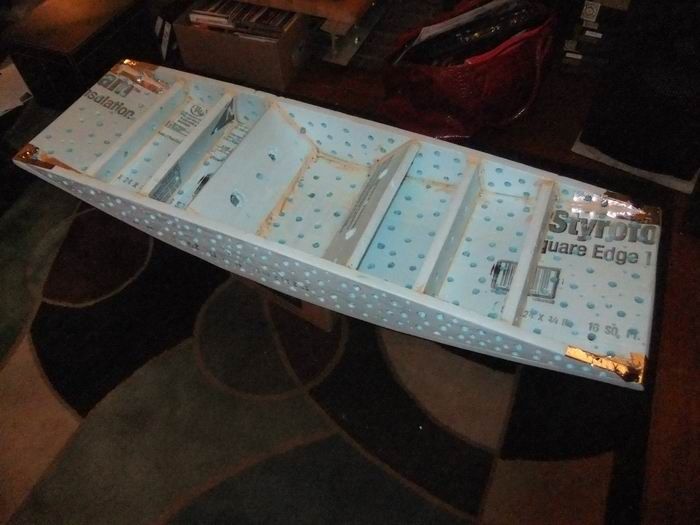

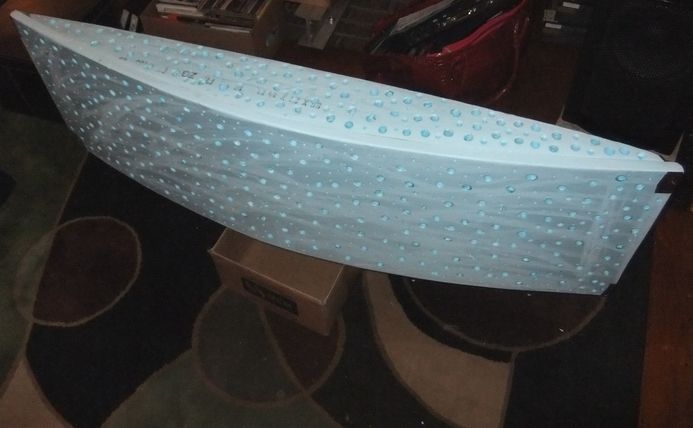

Building a center stage acoustic absorber which will be placed above the fireplace and below mantel.

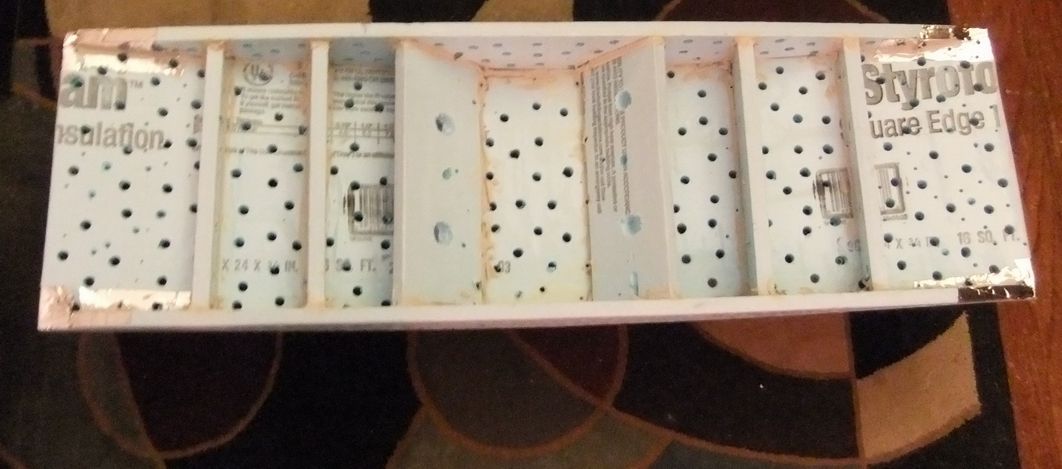

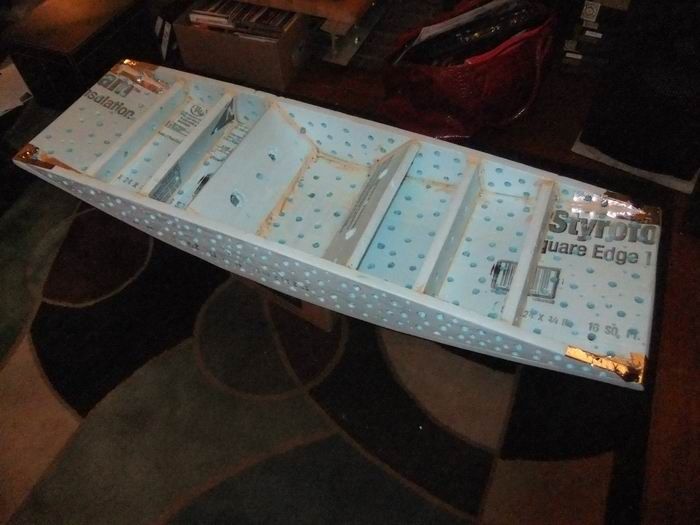

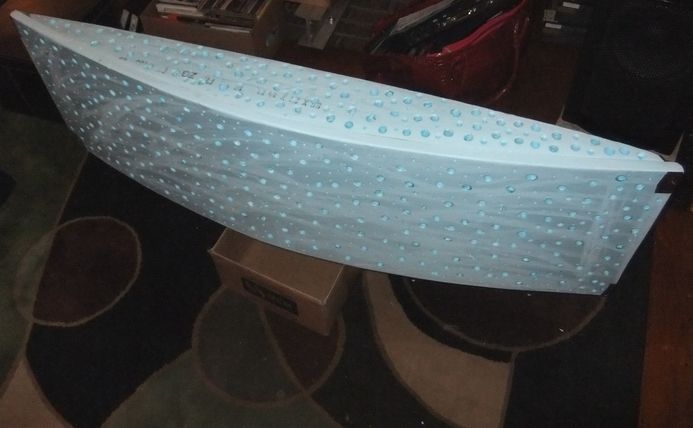

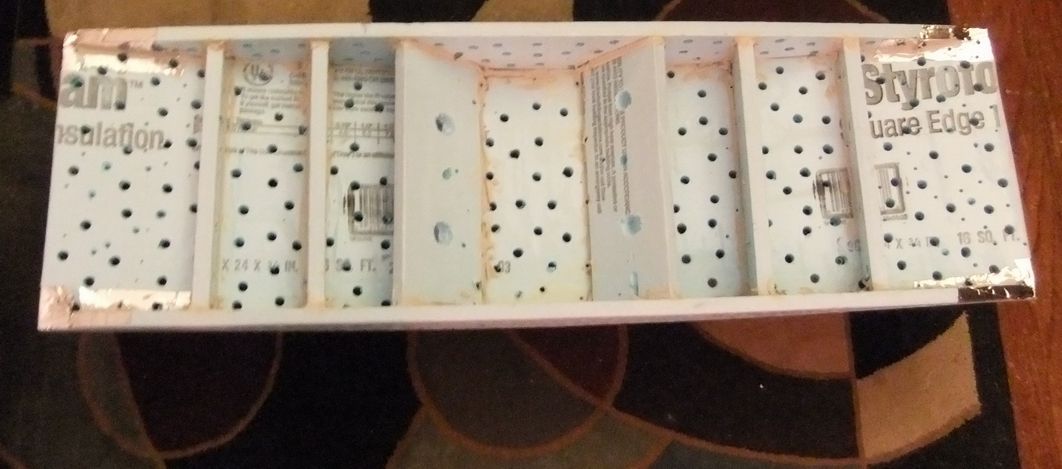

The concept is to allow sound waves in, have them bounce around a while in the cavity and dissipate energy. I placed some felt on the back face, about 30% of the open back exposes the brick, the perimeter is unsealed.

The traditional materials for this type of mid-band absorber is peg-board, on 2x4's wood studs with batten insulation infill. The pegboard gets covered with a fabric of course. You might see this high on the back wall of a church

A low and mid- range absorber would be a special hollow concrete block with holes or a slot in the face. the extra depth and density of the concrete allows the longer wavelengths to be contained and dissipated.

I also have rigid insulation covered with acoustic foam in the fireplace opening (behind the low center rack), some holes in the board to allow sound to get in, and hopefully trapped.

http://s184.beta.photobucket.com/user/kach22i/library/Stereo

Simple boxes and complex curves were sketched up, a form in the middle which could be easily built was settled upon. White school glue and painter's tape held it in shape at first. Later on, construction adhesive and foil tape at critical corners reinforced it all.

I was not 100% satisfied with the preliminary results, and the drill bits made a terrible mess of making holes. I used a soldering iron to make many more holes.

It sounded better now, but thought it was open to still more improvement, so I added the weather strip felting allow for some diffraction off the backing brick wall.

Here it is:

The sound is all cleaned up on vocals now, no extra sibilance even on heavily reverbed vocals. And the sound stage is complete, open and wide without the former patchiness.

Project:

Building a center stage acoustic absorber which will be placed above the fireplace and below mantel.

The concept is to allow sound waves in, have them bounce around a while in the cavity and dissipate energy. I placed some felt on the back face, about 30% of the open back exposes the brick, the perimeter is unsealed.

The traditional materials for this type of mid-band absorber is peg-board, on 2x4's wood studs with batten insulation infill. The pegboard gets covered with a fabric of course. You might see this high on the back wall of a church

A low and mid- range absorber would be a special hollow concrete block with holes or a slot in the face. the extra depth and density of the concrete allows the longer wavelengths to be contained and dissipated.

I also have rigid insulation covered with acoustic foam in the fireplace opening (behind the low center rack), some holes in the board to allow sound to get in, and hopefully trapped.

http://s184.beta.photobucket.com/user/kach22i/library/Stereo

Simple boxes and complex curves were sketched up, a form in the middle which could be easily built was settled upon. White school glue and painter's tape held it in shape at first. Later on, construction adhesive and foil tape at critical corners reinforced it all.

I was not 100% satisfied with the preliminary results, and the drill bits made a terrible mess of making holes. I used a soldering iron to make many more holes.

It sounded better now, but thought it was open to still more improvement, so I added the weather strip felting allow for some diffraction off the backing brick wall.

Here it is:

The sound is all cleaned up on vocals now, no extra sibilance even on heavily reverbed vocals. And the sound stage is complete, open and wide without the former patchiness.

Last edited: