Dear

@Balle Clorin,

In my opinion, there is nothing wrong with your turntable or its motor.

Lowering the motor voltage only works with AC motors. For AC motors, reducing the voltage lowers the torque while keeping the speed constant, as it is locked to the frequency. However, since your turntable’s motor is DC, lowering the voltage will decrease the speed.

The belt on your turntable is most likely sourced from Transrotor. If not, it is identical to the Transrotor mid-size belt. I recommend purchasing the Transrotor belt, as it is far superior to the Origin Live or LP Gear belts.

I have dealt with similar situations in the past, and in my experience, the following steps should help:

• Ensure the bearing is properly lubricated.

• Wash the belt with neutral hand soap and warm water. Clean the platter and pulley with IPA where the belt makes contact, and this time, do not apply talc to the belt.

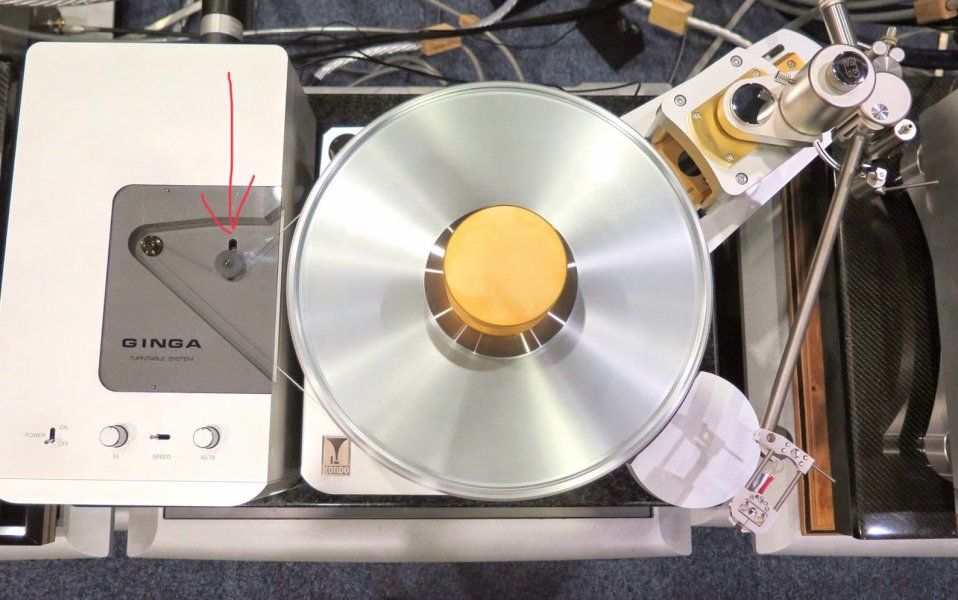

• The pulley does not appear to be properly installed. You may have tightened the screw too much, causing an imbalance. However, this kind of imbalance can also occur after removing and reinstalling the pulley due to slack. I have even seen this issue on new turntables.

• Remove the pulley and clean both the shaft and the pulley. If there is slack between them, wrap a very thin layer of tape around the shaft to enlarge it slightly, ensuring the tape does not overlap. The goal is for the pulley to fit tightly onto the shaft by hand.

• If the pulley is correctly installed and perfectly centered, you should not see any difference in its position between when the motor is running and when it is stopped. Ideally, you shouldn’t be able to tell whether the motor is running just by looking at the pulley.

I hope this helps!