As mentioned on prior posts (

@Mike Lavigne and

@Another Johnson) and technically speaking changing motor’s location doesn’t change the speed. Speed is related with diameter ratio of pulley and platter that belt rides on. But anyway speed may still slightly change when you move motor tower due to other reasons. You can check speed easily before every listening session. So, it’s not a big problem.

On the contrary separating motor from the plinth is a very good thing. By doing that you can eliminate motor noise and more importantly it’s vibration reaching to platter. Motor should be mounted on an isolated separate tower.

On the other hand mounting tonearm on a separate tower is not a good idea. Unlike motor, when a tonearm tower moves slightly whole cartridge adjustment ruins. It might be a slight possibility for heavy towers but it’s still a possibility.

In terms of vibration isolation, separate tower usually doesn’t have as good isolation as the plinth. Motor vibration and noise as well as other vibrations in the room might reach to tonearm more easily when tonearm is mounted on a separate tower. Additionally when plinth and tonearm tower have their individual isolations then there will be a compliance between them, they will move at different frequencies when a vibration hits them. It’s similar situation like installing a rubber between tonearm base and armboard. That’s why almost all modern tonearms are hard mounted on arm boards without any elastomers. It’s because direct coupling tonearm to plinth as

@PeterA recommends is beneficial. That’s why tonearm should be mounted on isolated plinth.

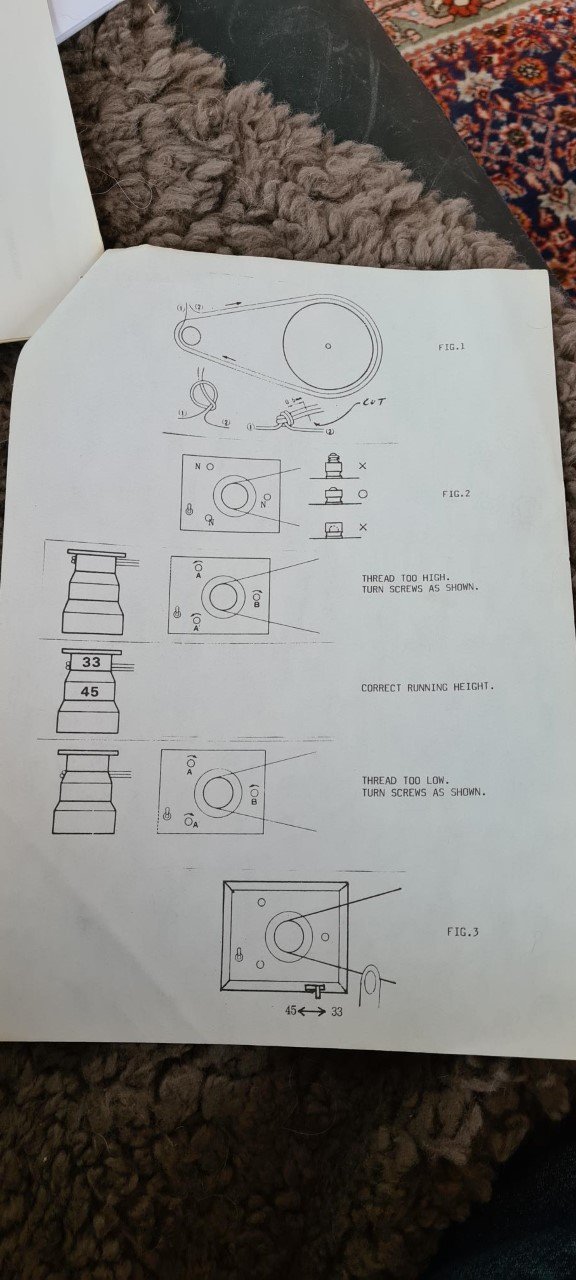

I learned a lot from my experiments with elastic belt to non elastic belt to dental floss to different non stretch threads. They all changed the sound I heard. I prefer the thin, strong special thread that ddk sent me. I concluded that the connection between motor pulley and platter is critical to the sound. The less influence the motor has on the platter, the better, at least in my case with a very high mass platter with very low rotational friction.

To further this observation and increase my knowledge on the subject, I am now embarking on a series of experiments with thread tension and thread length. Contrary to what others have mentioned, I have indeed observed changes in speed, both in terms of absolute speed accuracy (33.333RPM) and in speed consistency (+/- 00.002RPM), with very small changes in motor position. This is because a slight change in position (distance between motor pulley and platter) changes the tension of the thread. With any change in thread tension, I observe a change in speed. To compensate, I adjust the speed control on the motor to reach the right combination of speed and tension.

The looser the tread, the better the sound, at least in my application. My conclusion is that even though the motor is isolated from the turntable base and platter, some small resonance travels along the tread to reach the platter. In my case, the platter will free spin for 30 minutes before stopping, so very minimal influence from the motor is necessary to maintain constant and consistent speed. The RoadRunner tachometer readout is to three places. It is measured only once per revolution, but there is no control on the motor based on this readout. I can see exactly much changes in thread tension affect speed. And it is audible.

Encouraged by what I heard with lower thread tension, I decided to adjust the length of the thread. My separate motor unit makes it easy to move the driving pulley and alter its distance from the platter. Thread length, as well as its tension, affects its resonant frequency, and thus the influence of the motor on the platter. This is audible. My thread is now loose and long and after some adjustments to the tension and motor speed, I have accurate and consistent speed again.

Even though the motor unit itself is isolated and sits on a massive steel plate which itself is isolated from the separate from the differently isolated steel plate the turntable bass sits on, the further distance seems to help with noise from the motor. The loose, long thread, also reduces the motor's noise and influence further.

The resulting sound is more natural, especially in the bass. This then affects higher frequencies in terms of clarity. The sound opened up, and with the lower noise, I hear more information. I am really pretty surprised at how much of a difference this makes.

I ran into an interesting thing though as I moved the motor away from the platter. The thread angle changed, resulting in the thread rubbing against two of the arm posts. I wondered if this affected the sound because of the friction and angle change. The tension was loose and the thread was thin, but I moved the motor and rotated the turntable so that the thread no longer rubbed against the arm posts. Sure enough, this was audible too. In the photo below you can just see how the turntable is rotated and that I moved the motor to the front of the top shelf so the thread would have a clear path.

So I agree that set up matters a lot with turntable performance. I now appreciate the flexibility that my separate motor allows. I agree with those who prefer captive arm boards. Any movement here is detrimental to alignment and to sound. One can address the arm isolation issue with platter bearing design and motor isolation to reduce noise traveling to the arm.