General Question about Belt Drive Turntables

- Thread starter dminches

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

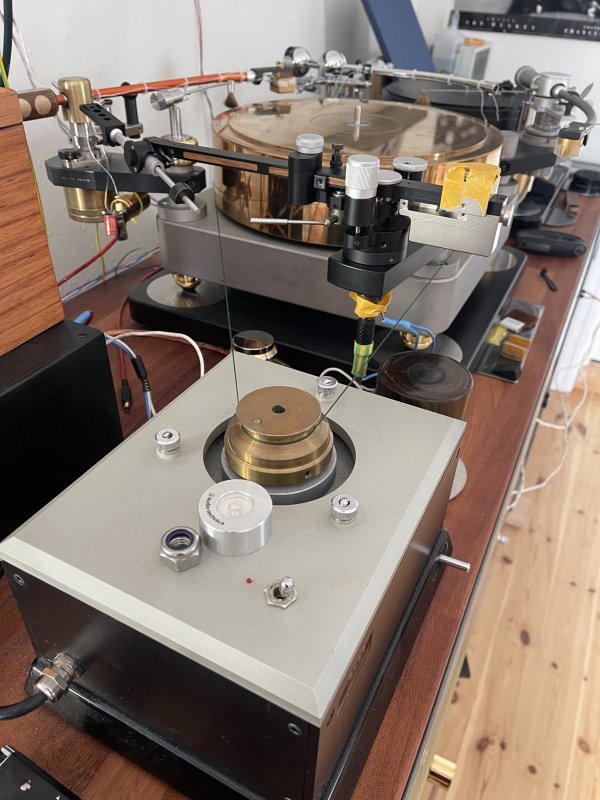

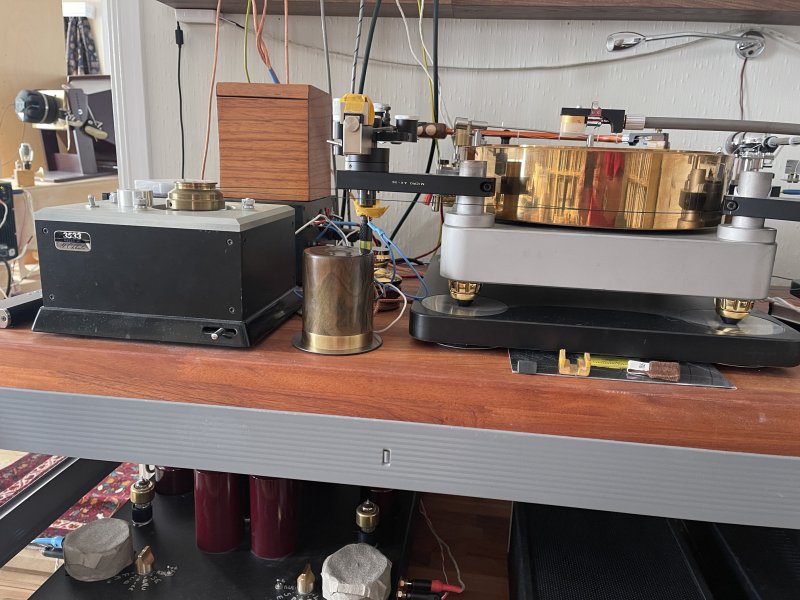

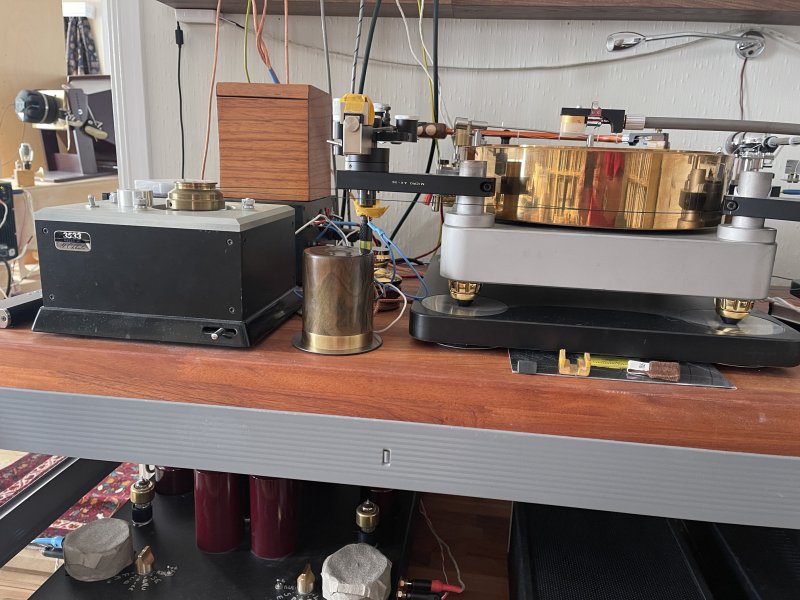

My Melco plinth is placed on a separate marine MDF slab that is placed on 200Kg sorbothane pucks on a 70mm African mahogany top shelf in the rack

The motor unit is placed directly on same mahogany top shelf

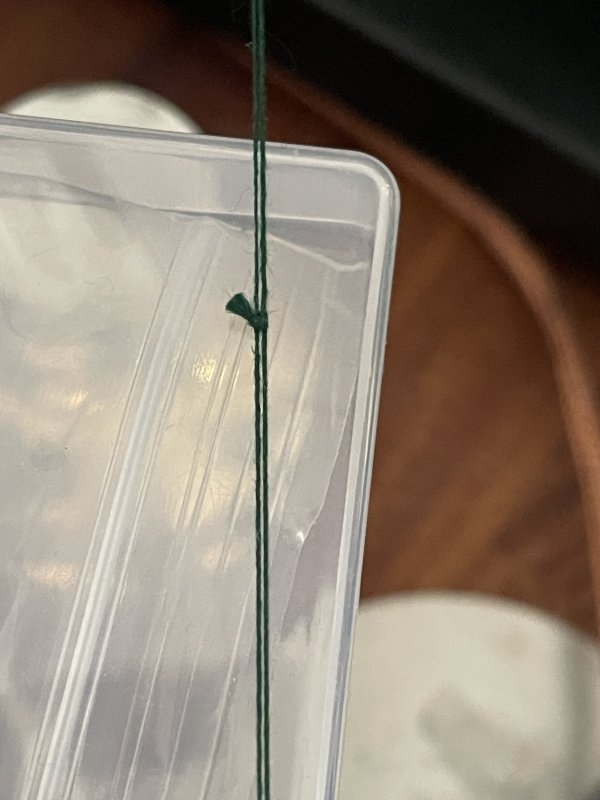

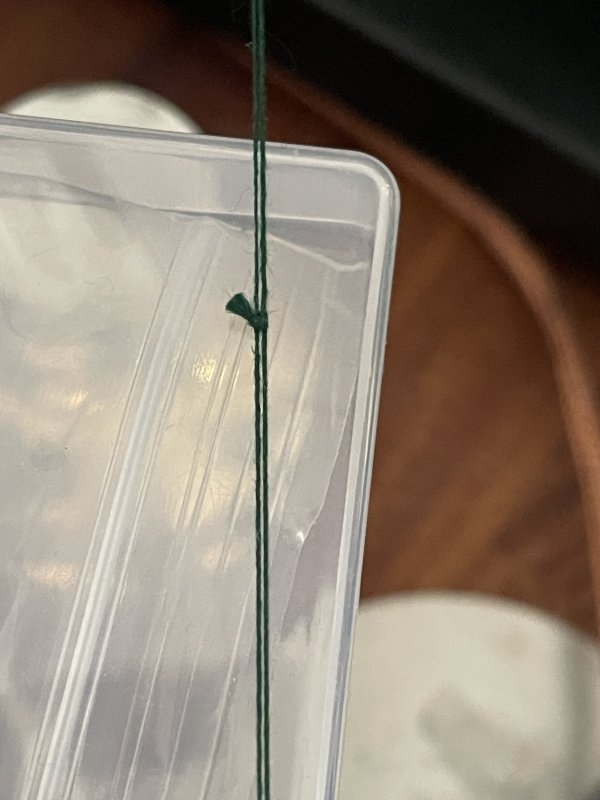

reg the knot; I can feel it with my fingertip on the outside of the thread, but not on the inside

The motor unit is placed directly on same mahogany top shelf

reg the knot; I can feel it with my fingertip on the outside of the thread, but not on the inside

Attachments

Thanks Lief, that knot does look very smooth ?My Melco plinth is placed on a separate marine MDF slab that is placed on 200Kg sorbothane pucks on a 70mm African mahogany top shelf in the rack

The motor unit is placed directly on same mahogany top shelf

reg the knot; I can feel it with my fingertip on the outside of the thread, but not on the insideView attachment 125545

View attachment 125542View attachment 125543

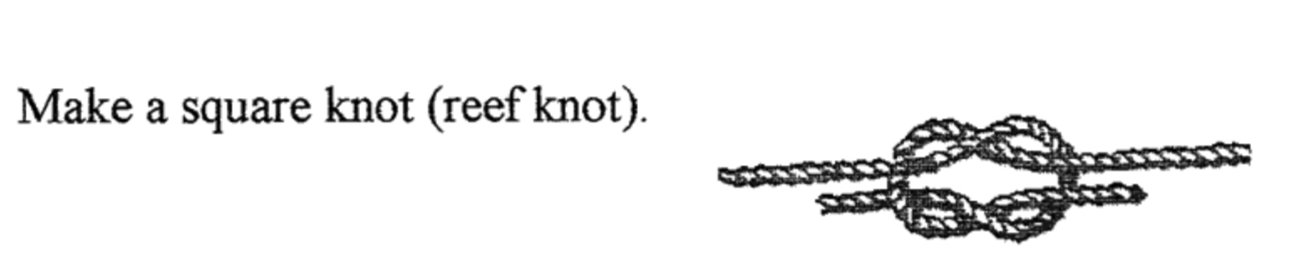

I reserve that knot for my sailing boatI used to use this knot with string. Minimal bump over the pulley.

View attachment 125541

Good idea. Although I spent 20 years onboard of boats and never need a knot.I reserve that knot for my sailing boat

Last edited:

btw when I had tt in living room I had motor assy on top of separate VPI rack and plinth on other.....couldn´t detect any results from assymmetrical movements in separate racks

but sonic profit from getting all sources and most of the electronics into adjacent separate machine room was dramatic

but sonic profit from getting all sources and most of the electronics into adjacent separate machine room was dramatic

in the machine room or on the bridge?Good idea. Although I spent 20 years onboard on boats and never need a knot.

On all compartments and all duties. Engine room, control room, conning tower, CIC etc.in the machine room or on the bridge?

Last edited:

You’re right and I still remember some knots but it’s a different kind of boat. Submarine is not the first thing comes to mind when the word boat is mentioned but she is also called as boat.need knowledge of many different knots on a sailing boat

and often no time to hesitate

Last edited:

I was @Kobben-klassen submarine as sonar operator....loved it

I served on board of Guppy IIA, Tang, Type209 and Type209 Mod1400 class submarines.I was @Kobben-klassen submarine as sonar operator....loved it

I know. Type205.the Kobben was a small quiet sub with only 18-20 crew

Both US and German type subs in Turkey.in US? or Germany?

Now there is a thread tangent I never expected!I served on board of Guppy IIA, Tang, Type209 and Type209 Mod1400 class submarines.

Now there is a thread tangent I never expected!

You do get the background though - They got so used to sitting in enclosed chamber using a sonic radar, listening to the same echo of the same sonic signal - so you can see how that experience translates to get them where they currently are.

Tone deaf?You do get the background though - They got so used to sitting in enclosed chamber using a sonic radar, listening to the same echo of the same sonic signal - so you can see how that experience translates to get them where they currently are.

Hello the kong. I use this solution. on a solid tech table I replaced the last shelf with a 2.2 cm sheet of marine MDF. Above this I positioned a first 3 cm slab of marble then a 4 mm sheet of industrial rubber and on top of yet another 3 cm marble slab the last marble slab is cut with the final U-shaped part and the marble obtained from the U cut I had smoothed to 1 mm on each side in order to physically separate it from the rest of the slab and on this I positioned the motor unit of my VPI HR X. and the result is remarkable with a considerable increase in the dark backgroundThanks Peter! I have never thought of separate top shelves on the same rack, certainly something to try !

Just getting sources and speakers of the same floor helps a lot, mine are actually on 2 separate parts of the foundation and absolutely no connecting wood flooring.btw when I had tt in living room I had motor assy on top of separate VPI rack and plinth on other.....couldn´t detect any results from assymmetrical movements in separate racks

but sonic profit from getting all sources and most of the electronics into adjacent separate machine room was dramatic

Yes it can be hard to keep the periscope on target at all times in some of the threads !Now there is a thread tangent I never expected!

Similar threads

- Replies

- 199

- Views

- 38K

- Replies

- 24

- Views

- 6K

- Replies

- 2

- Views

- 4K

- Replies

- 112

- Views

- 24K

- Replies

- 371

- Views

- 49K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |