About 4 weeks ago my friend Bob who goes to all the shows with me came over and we went through an exercise of comparing a stock SqD QO loadcenter to one of my fine tuned SqD NQ all copper panelboards. You can see better what I did on Audiophile Junkies Youtube. In short we used the same feeder with the same 2 branch circuits on the same 2 breakers and swapped one panel in, then the other. It took about 10 minutes to swap the panel and get back up to the room.Rex, having worked with you on my home's power system, my curiosity begs me to ask the following. How far do you get by having a very well executed panel and ground plane fronting your audio system. Because you do have that, can that be the reason you're not hearing a benefit from the Puritan hardware?

My personal observation only goes as far as the Shunyata grounding products. Their recommended implementation is what I've heard multiple times in different systems and, in my experience, provided a consistent level of perceptible improvement. As you note, it also requires a significant investment($). Yes, it usually requires time to go through the process. You have to let the hardware 'mature'.

We were both shocked at the change. The all copper NQ panel was notably more quiet in the room. There was a very audible sibilance through the entire frequency range that was removed. We both felt it was on a magnitude of adding a Torus.

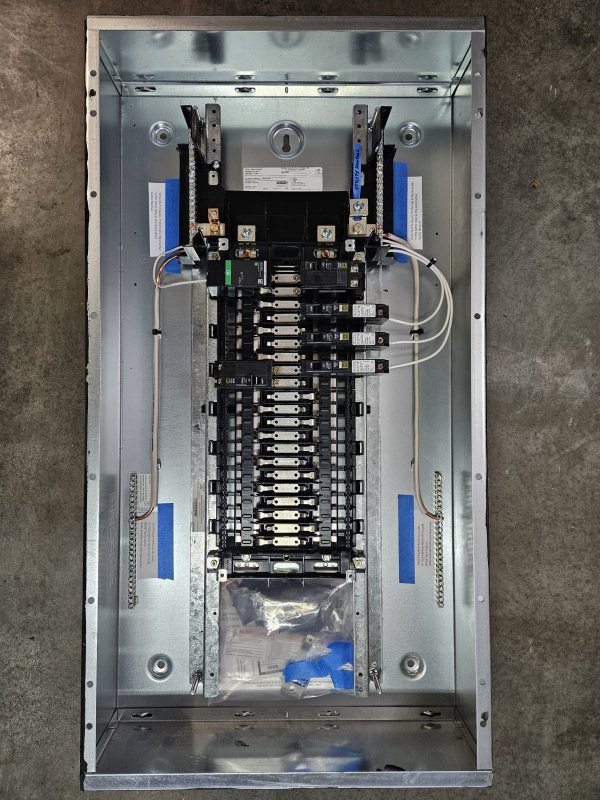

Take a look at these images. A QO loadcenter is commonly landed as per the marked up image. Then look at my NQ panelboard Neutral/ground termination. The NQ panel is solidly bonded between neutral and ground. The ground terminals are solidly bonded to the neutral. They are for the most part as single point bonded as I can make them.

Remember, the loadcenter is all aluminum. The NQ panel I make is all copper. Copper conducts better.

Also, I have never seen a loadcenter in the field where the electrician bonded the ground to neutral with a copper wire. They always rely on the heavy green screw through the neutral bar into the can effectively bonding the can to neutral. Now the can is the current conducting path for all the branch circuit grounds and maybe the earth ground between the ground bar and utility neutral termination.

The relationship between the utility neutral and ground bar is of paramount importance. It is hugely important when it comes to shunting surges to ground. Think how much work a surge has to go through to get from the utility to earth in a loadcenter. In my panel is a direct down traveling path from utility to earth. In a load center it has to go through screw and a metal can.

I don't know how much bearing all this has on a ground box. Its possible the ground is much more effective in my panel and actually draining some noise. I know I have always said an earth ground should not be heard. But properly grounding/bonding in any panel I have touched has almost always had an audible affect of lowering noise you sense in the room. It can be very audible or subtle. Maybe a Shunyata ground box would be more effective. I do believe Caelin is a talented engineer and has the skills to make a ground box that could be superior to others.

It could also be removing the aluminum grounds and neutrals reduces a lot of galvanic reaction between the copper branch wires and the aluminum. There is a notable amount of noise that goes away when you insert a all copper panel. I had a customer last night replace his load center and with a one of my panels and immediately heard a change for the better in noise and in bass response.

You might have to download the pdf to view them. I do not have them in a JPEG as I marking them with a PDF tool.