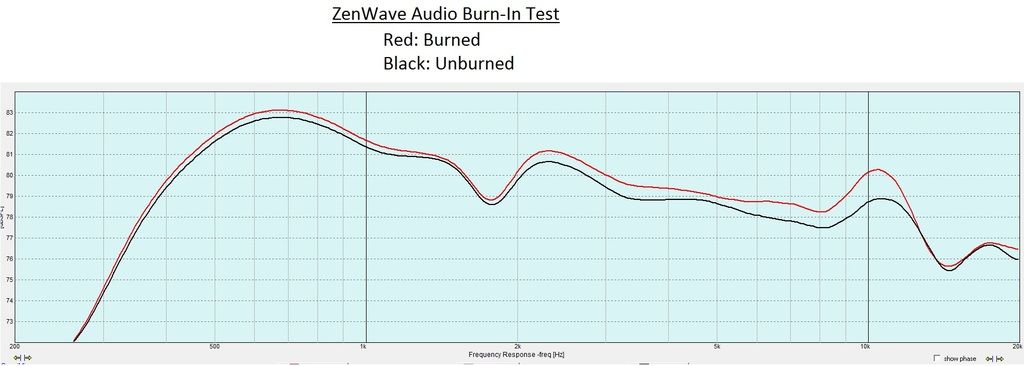

(...) Cable used was ZenWave Audio SL17 speaker cable which uses an aggregate 17g of UPOCC copper litz wire. Litz wire has a much larger surface area in contact with the dielectric vs conventional wire and burn-in effects are very pronounced with this cable vs cables made using conventional wire. (...)

Interesting. You are correct that litz wire should be very sensitive to burn-in - you use more than 1000 insulated strands of 50 micron diameter, meaning that you have a very significant contact area between metal and insulator. The varnish used to insulate the wires is usually an "imperfect" dielectric, with relatively high dielectric absorption - a good candidate for dielectric defects!

The difference you report can be easily seen in the electrical domain- and them people will not question the measuring technique and repeatability. We could even carry a null test between a new and a burned-in cable. Unfortunately I sold my Cello String cables long ago - I remember they were heavy litz type - otherwise I would try to duplicate your experiment.