Actually I’ve almost abandoned Tite Bond now. If you can believe it, gorilla glue is my fave. It’s strong as hell, and not overly expensive.Good ole Titebond will do the trick and reverse grain orientation is tried and true. Good technique. I like the Festool mortise and floating tenon tool to further enhance the joint, but also to help with board alignment during the glue up. Kind of like biscuit joinery but with massive biscuits. I don't have a wide belt sander, so good alignment really saves a lot of work. I also agree on the likelihood of solid slab warpage over time. One thing I've found, though, is that both plywood shelves and butcher block shelves sound pretty bad. And the way I look at it is that laminated slabs start to approach what plywood is while the edge joined boards start to approach butcher block. I'd go with the edge joined approach and try to use no more than three boards to obtain the final shelf width. This creates a dimensionally stable platform and minimizes glue joint surface area (which I suspect is key to avoiding dead sounding shelves) vs the laminated plank construction. So, I like the Massif build.

Mike, when do these go in? I don't envy the work that will be involved in swapping racks but the end result ought to be quite satisfying.

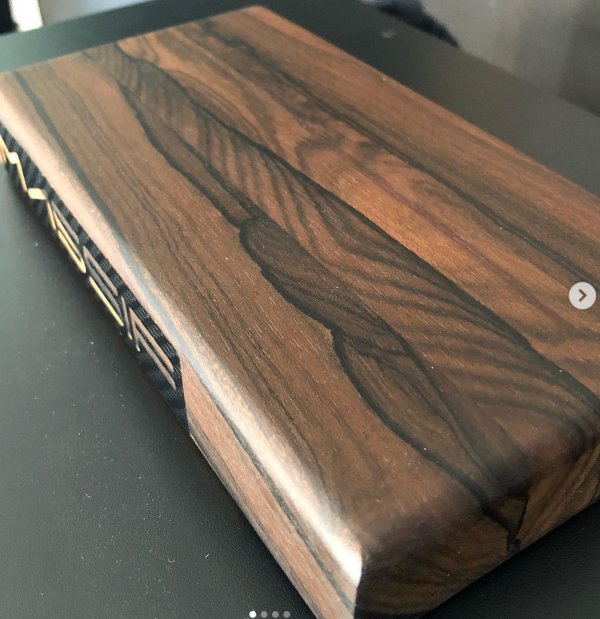

PS Bubinga is one of my favorite woods. Gorgeous!

I don’t need the Festool domino maker for shelves really. I have a huge jointer and planer so my shelves are always 100% flat before I glue them up. But yeah many people don’t have that luxury. I’ll tell what I do have that is a life saver, a Festool track saw. It’s maybe the finest single tool on the market. Take care