SUB-100Hz BASS

DEEP BASS is a hugely tough beast to slay because of its omnipresence and omnipotence in the listening room, creating modal augmentation and cancellation issues. To ascend, and scale to the peaks of this majestic mountain, huge boulders and slick ice faces are the metaphorical equivalent of the bass energy which us audiophiles are trying to conquer.

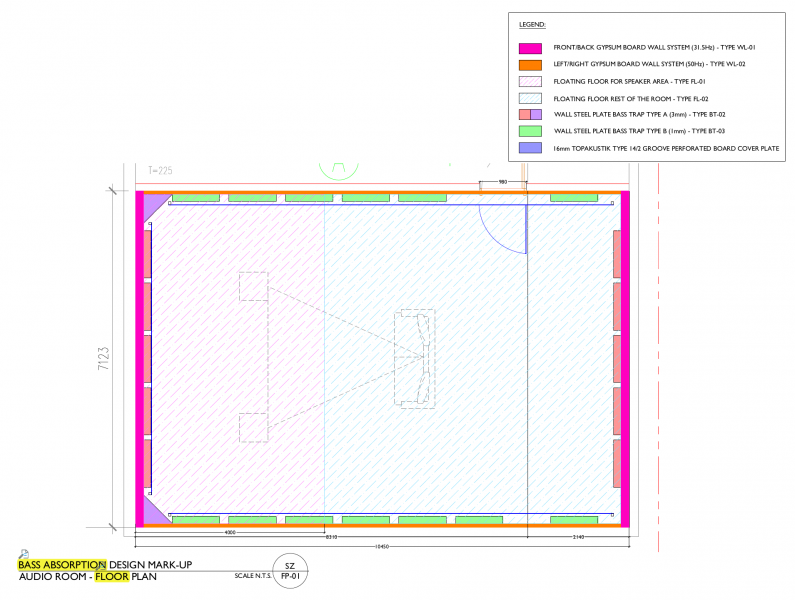

Below are some basic descriptions and diagrams of the hardware which I'm considering installing in my basement listening room. The exact design specifications and materials are proprietary; hence I'll need to describe them in generic terms.

Since few audiophiles have built listening rooms of this caliber (and have shared all of the nitty gritty details on the art and science), in addition to my extremely competent and experienced "hired gun" acoustician, I've had to independently challenge, evolve, and iterate the final design, using numerous cross-references (audio forums, books on room acoustics / psychoacoustic, content providers on YouTube, contributions from fellow audiophiles, etc.) regarding the application, effectiveness and performance of the room's great many individual components, just to be doubly sure I wouldn't be accepting anything superfluous, or worse, end up regretting, because that would be even more costly to eviscerate and rebuild. The journey has been challenging, but fun and hugely educational!

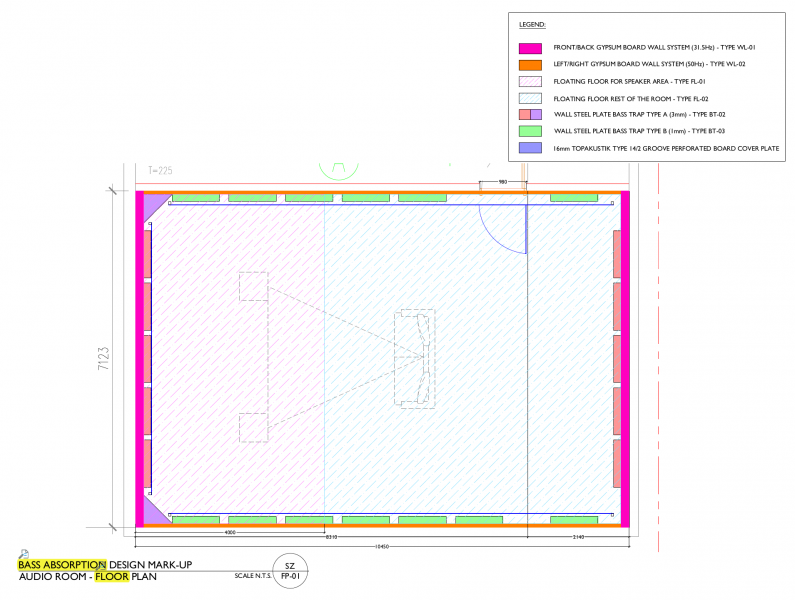

THE FLOOR

Four meters will be allocated to the speaker area, equal to ~38% of the room length, and the remaining six meters will be allocated to the listening area. The two sections of the floor will be physically separated - constrained-layer dampened, decoupled, floated, and grounded - sandwiching dissimilar energy-absorbing materials.

The speaker-area floor will be constructed with the following, starting from the RC structural floor substrate:

- 4mm+ high-density recycled rubber granule underlayment for under-screed/floating floor constructions

- 90mm+ high-density screed, with BRC mesh in the center for mechanical integrity/strength

- high-durability leveling compound

- perimeter decoupled from adjacent structures via sponge rubber strips + caulking

The listening-area floor will be constructed with the following, starting from the RC structural floor substrate:

- high density foam isolation strips (tall, providing vertical clearance), covered with steel C-channel support

- 50% of the space will be filled with 100kg/m3 Rockwool insulation, 50% of the space left as an air gap

- structural steel decking (thin)

- 45mm+ high-density screed, with BRC mesh in the center

- high-durability leveling compound

- perimeter decoupled from adjacent structures via sponge rubber strips + caulking

The loudspeakers (and subwoofers) will have a more solid/stiffer floor foundation from which they will launch their acoustic energy, but energy propagating through the floor will decay rapidly before it reaches the listening area.

The wall treatment will be as follows, addressing different axial mode frequencies between the different distances between the structural slabs/walls. VPR is the German word for Verbundplattenresonator, which translates into "plate resonators". They are extremely effective!

(visit the following link):

THE FRONT/BACK WALLS (axial mode target frequency of 31.5Hz)

Starting from the RC structural wall, there will be a double-layer sandwich of gypsum drywall

- 100mm free air space

- 50mm Rockwool (100kg/m3 density)

- vibration absorbing isolation wall bracket

- 12mm+ thick gypsum board (550kg+/m3 density)

- acoustic damping sheet (self-adhesive) applied in the center of the double drywall sandwich

- 12mm+ thick gypsum board (550kg+/m3 density)

- VPR absorbers, with 3mm thick steel plates

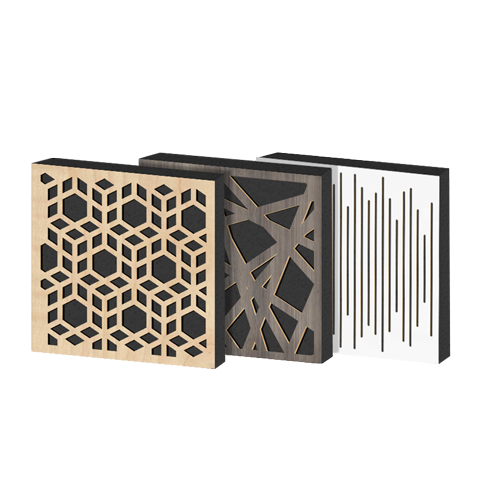

- covered with perforated wood groove panels from floor to ceiling, for a wall-to-wall uniform look

THE SIDEWALLS (axial mode target frequency of 50Hz)

- 50mm Rockwool (100kg/m3 density)

- vibration absorbing isolation wall bracket

- 12mm+ thick gypsum board (550kg+/m3 density)

- acoustic damping sheet (self-adhesive) applied in the center of the double drywall sandwich

- 12mm+ thick gypsum board (550kg+/m3 density)

- VPR absorbers, with 1mm thick plates

- covered with perforated wood groove panels from floor to ceiling, for a wall-to-wall uniform look

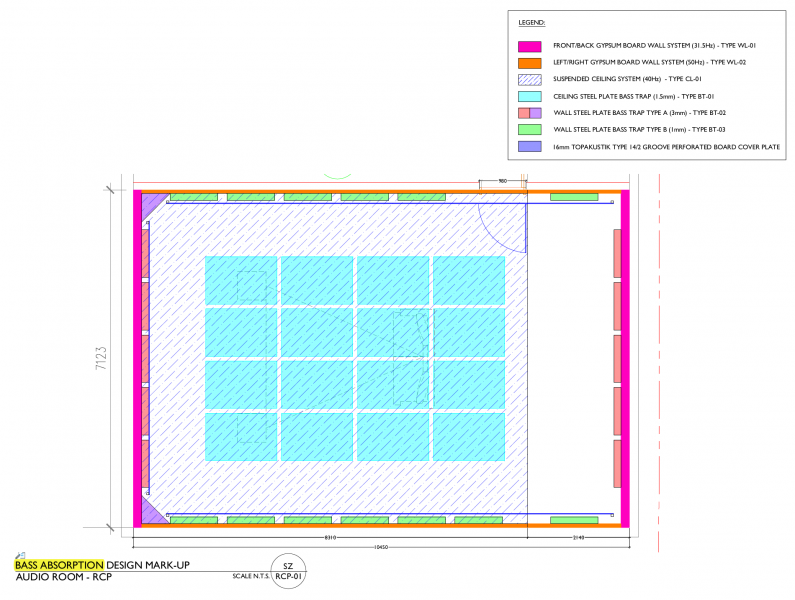

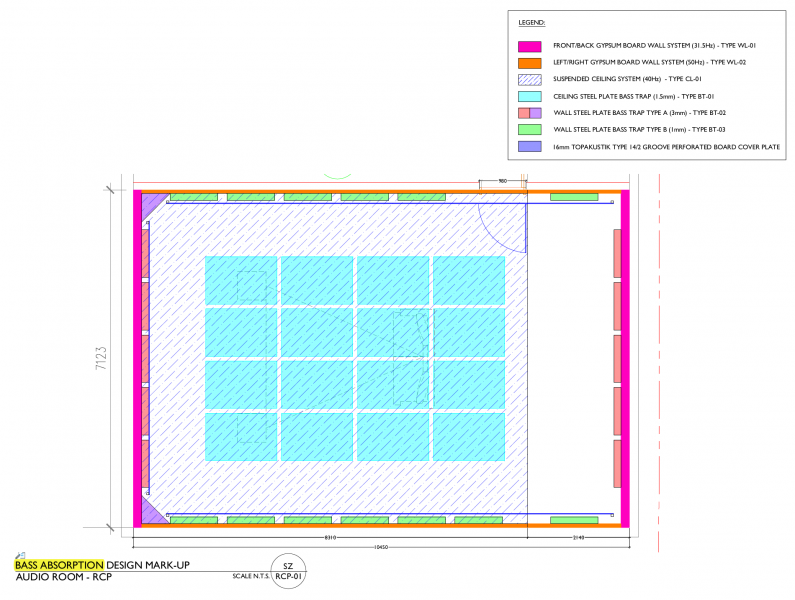

THE CEILING (axial mode target frequency of 40-50Hz)

- 240mm+ free air space

- 50mm Rockwool (100kg/m3 density)

- 15mm+ plywood (600kg+/m3 density)

- acoustic damping sheet (self-adhesive) applied between plywood and gypsum board

- 12mm+ thick gypsum board (550kg+/m3 density)

- VPR absorbers, with 1.5mm thick plates

> additionally, suspended ceiling bracket system housing a large canopy of solid wood 2D diffusers