That SAT TT has been severely beaten with the ugly stick

Now wait for Fremer to come riding in for the rescue

Now wait for Fremer to come riding in for the rescue

I think David should get this motor for AS 2000 premium.

Did you forget the smile again?

Thank you for posting this link Tim. It reads more like a press release than anything else, with surprisingly few specifics. I do find it interesting that there are new DD designs hitting the market: the new VPI, this SAT, the new Technics - adding to the GP Monaco, the older Brinkmann Bardo and NVS, to name a few. I wonder if with superb execution, there is really much audible difference between these and the high mass belt drives. Differences may be more about how internal resonances and vinyl/platter interface are handled than about the drive technology per se.

There seem to be a number of members here who have done some research on motor technology. I too wonder about that claim for the Technics motor. On what is it based, and how was testing performed? I think its great that a large company like Technics has reentered the turntable/motor drive area. Their scale and R&D budgets can only be good for the industry.

I now wonder if Marc Gomez releasing his turntable design was a factor in his relationship with TechDAS. It's a pretty fascinating time for turntables and analog in general. Perhaps I am viewing it from a very limited perspective though. I wonder what people like David K and Hideaki Nishikawa think from their much longer perspectives. Is much changing, or is it just more of the same with different materials. Is this really just not that significant given the tiny interest in high end vinyl?

battle lines being drawn, nobody's right if everybody's wrong.....

Yes you could both have saved a lot of trouble and research and simply pimpedI'm just as impressed with the table as I was with his ultra 9"’er but I have a feeling that Nishikawa San is even more impressed than me!

david

Yes you could both have saved a lot of trouble and research and simply pimped

out a Technics TT. Go figure

This is going to be hard for Fremer, he just loves SAT, but Techdas has probably a much larger marketing budgetAnd he is their favorite DJ.

Well, mono and stereo rates it as the best motor

Is there a price mentioned anywhere for this SAT table? Or is it, if you need to ask, you can't afford it

Technics DD motor - the best motor

We have analysed and compared all motors used by other manufacturers and nothing comes close to the Technics SP-10R drive system. It is the most powerful, accurate, quiet and reliable motor available today for this application.

Using the Technics motor and controller system lets the manufacturer focus more on the mechanical design, which seems to be his forte. No need to mess around with digital controller technology and software which is where the real work is for a DD drive system. Interfacing the real world, ie. what's happening real-time with the platter, to the digital world of the controller can be done in a variety of ways and not all ways are equal.

Yes, but the manufacturer will inherit the sonic signature of this motor hardware and controller. The coupling of the platter to the plinth is made by the bearing but also by the driving forces in the turntable going through the motor structure - and in this case this path is pre-defined by Technics.

Thank you for posting this link Tim. It reads more like a press release than anything else, with surprisingly few specifics. I do find it interesting that there are new DD designs hitting the market: the new VPI, this SAT, the new Technics - adding to the GP Monaco, the older Brinkmann Bardo and NVS, to name a few. I wonder if with superb execution, there is really much audible difference between these and the high mass belt drives. Differences may be more about how internal resonances and vinyl/platter interface are handled than about the drive technology per se.

There seem to be a number of members here who have done some research on motor technology. I too wonder about that claim for the Technics motor. On what is it based, and how was testing performed? I think its great that a large company like Technics has reentered the turntable/motor drive area. Their scale and R&D budgets can only be good for the industry.

I now wonder if Marc Gomez releasing his turntable design was a factor in his relationship with TechDAS. It's a pretty fascinating time for turntables and analog in general. Perhaps I am viewing it from a very limited perspective though. I wonder what people like David K and Hideaki Nishikawa think from their much longer perspectives. Is much changing, or is it just more of the same with different materials. Is this really just not that significant given the tiny interest in high end vinyl?

In the presentation of AF0 launch on 16 March, Nishikawa san compared the difference between bent drive and direct drive turntable. Direct drive is good in controlling the rotational stability because platter on bent drive TT is free to rotate and only inertia can help to stabilize rotation.

The main problem with direct drive is the central axial is relatively small. This shaft from the motor has to support the platter. If the platter is heavy, as with most cases, the shaft will not be able to hold the platter in a stable position. Air Force series turntable uses the whole diameter of the platter, ie 12", as air bearing, so they are more stable.

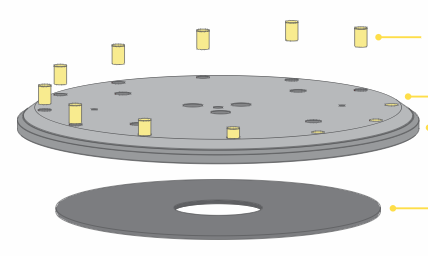

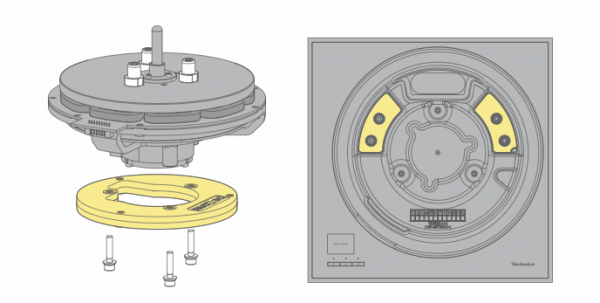

Nishikawa san point is on the vertical stability of the platter. It is difficult if not impossible to machine a platter to mount exactly perpendicular to the central shaft. During rotation, some vertical vibration will present. If the shaft is not strong enough compared to the weight of the platter, the vertical movement will be amplified.i have no dog in this fight; however the idea that the SP-10R falls under the case made by Nishikawa san that 'the shaft will not be able to hold the platter' seems to not apply as the SP-10R uses not only a shaft, but apparently from the diagram also three large bolts farther from the center shaft to maintain rigidity. hard to imagine any lack of rotational transfer occurring with that approach. if i have stepped in it here and misunderstood the picture (or the point made by Nishikawa san) then apologies of course.

i suppose it's possible that those three holes in the platter which line up with those bolts are only for access and don't actually secure the platter. maybe someone can clarify that for us.

i also think that execution and not dogma rules the day most times. so we need to listen before we anoint.

View attachment 50925

View attachment 50924

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |