I know this old arm is good but I don’t know why David,Rockitman,Tang,Ron,Mike

Use or will use having top tonearm like Sat,EliteAxiom,Black Beauty,Durand

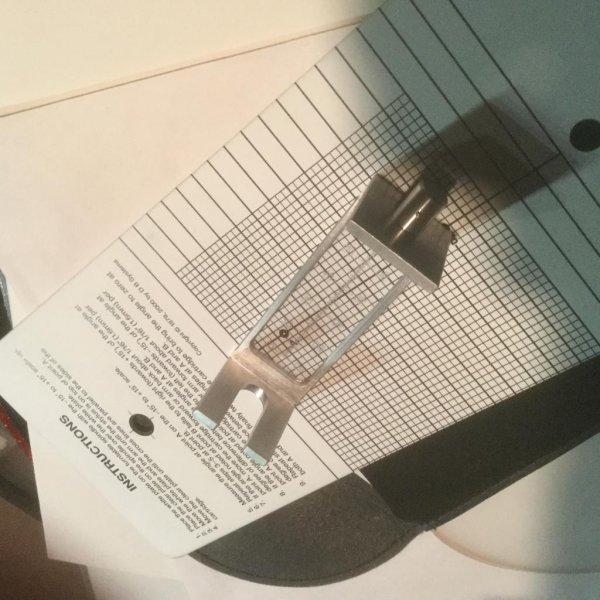

Why 3012 is so special?

I never had and I don’t understand

Only to know for my curiosity

Regards

Gian

Use or will use having top tonearm like Sat,EliteAxiom,Black Beauty,Durand

Why 3012 is so special?

I never had and I don’t understand

Only to know for my curiosity

Regards

Gian

Last edited by a moderator: