I'd certainly be interested. This is fascinating stuff, to be honest. I'd love to see pics of your builds in progress. I would assume that by now you have routing templates and jigs, vacuum lamination and veneer presses, etc? How many would-be plinths do you generally discard - i.e. the whole process sounds very much "trial and error".Since I think I may be the original instigator here - Remdeck and Peter had asked some questions in my OP "Blond on blonde... On blonde" thread here: https://www.whatsbestforum.com/threads/blonde-on-blonde-on-blonde.30295/

From my experiences in building plinths, a constrained layer approach has worked best for me by far. When I first acquired a Garrard, I tried a stacked birch ply plinth. It was cheap, easy to build and it seemed to be what a lot of people were using at the time (Art Dudley are you out there?)... It worked okay and I loved the sound of this new turntable, in comparison to the VPI Aries I had at the time.

I am a guitar player and something made me start to wonder about using tone woods in a plinth - what works well for a musical instrument seems like it should also work for a plinth, right? I had been reading about the Shindo Garrard and also the plinths from ____ . My next plinth was made from two layers of 2-inch hard maple, with the grain running opposite in each layer - four inches total. If you happen to play guitar (or another instrument that uses maple - mandolin, violin, etc.) you'll know that maple is less warm, more linear, and has a "crisper", more extended top end; as apposed to something like Mahogany which is, generally speaking, warmer sounding. Long story short; the birch ply plinth ended up in the fire pit at a backyard party.

Since this, I have experimented with other tone woods - cherry, ebony, mahogany, and Engleman Spruce. They all sound different and I like them all for different reasons/applications. My experience suggests always using hardwood as apposed to softer woods like pine, soft maple, etc.

At some point I heard about Panzerholz and thought I would try that. I have since found that I really like using it as long as it's "layered" with other materials. In my Technics SP10 Mk.3 plinth I use it more extensively than in my Garrard plinths, because I want the Garrard to be a bit less damped. I also used a 1 inch plate of a aluminum in the SP10.

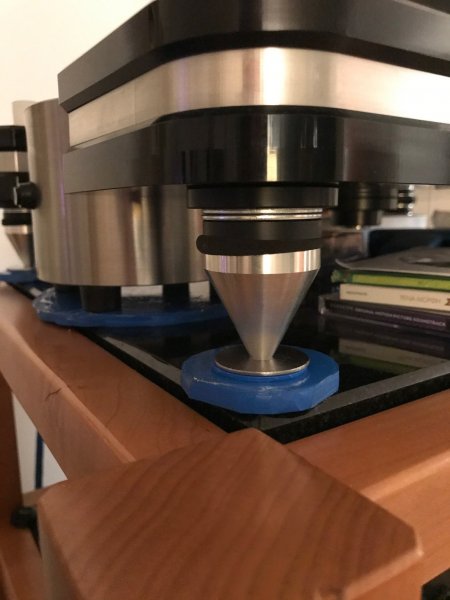

For the most part, I have built my plinths with a detached/seperate arm pod. I tried to make these arm pods as inert and damped as possible and they are almost 100% panzerholz on the inside. They are capped with either ebony or hard maple.

In my most recent plinth build I incorporated a layer of 2-inch bamboo - I was able to find a really large and thick bamboo cutting board on Amazon. I'm still tuning this 'table but so far I think the bamboo is a winner.

I have also started to experiment more with soapstone. It has some very interesting acoustic properties - much different than slate for instance.

Lot's more I can share and I will also try to post some pics later if anyone is interested.

The Effect of Damping on Sound: Racks and Turntable Plinths

- Thread starter remdeck

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"In theory, there's no difference between practice and theory. In practice, there is." Your theoretical questions are what led me to Sorbothane quite a while ago. My ears are what have made me stay away from it entirely now. With my recent base plate experiment, I was once again curious, and not at all surprised by what unfolded.

Simple answer: I don't know. I don't know the resonance and isolation properties of Sorbothane. Perhaps this material is inefficient at transferring mechanical energy to heat. Perhaps it has resonant properties of its own that have a causal relationship with the results in audio systems. The dumbed down mental model I have of Sorbothane (to attempt to explain what I hear) is that it somehow resists energy transfer, possibly even reflecting or amplifying kinetic energy back into the component that it is supposedly isolating. Tubed components in particular will pick up environmental energy and all electronics have self-resonating properties. It seems that at some point, when we hinder energy transfer from a component (as my mental model of Sorbothane says), the worse our results become - muddy, smeared, blunted, etc. I think there is a balance to be found between absolute isolation and absolute coupling as well. The latter tending towards overly sharp, under damped, dry, analytical, etc. The right balance may differ from person to person, system to system. You'll know it when you find it, most likely. It does get tedious though... even on a rainy day during shelter-in-place edicts.

I wouldn't jump to the assumption that everything that sounds right is because energy transfers better into it. In fact if something is very hard and heavy you expect it to be reflected.

If a car runs into a big piece of weird staining rubberish stuff, or it runs into a thick steel wall...

One issue with amplifiers, whether SS or Valve, is that they generate their own resonances and most are built into a metal chassis that is far from dead to begin with. Tube amps, especially something like an 845 with relatively high current thoriated filament and 1200v B+ send generated energy into the chassis, and unless the power and output transformers are heavily potted, you have mechanical resonances emanating from those sources. Even if potted there are some. Sorbothane breaks the mechanical grounding. It will damp some resonance that makes it to the feet or bottom of the chassis, but you are isolating that component from a path to drain resonance out of the unit. Meanwhile you are partially isolating the amp from floor-carried vibration, but selectively. Sorbothane seems to me much less effective at low frequency isolation than highs, net result being that the amp is still disturbed by low frequency resonance which further complicates the problem of getting mechanical resonance out of the amp. Amps of any type generally sound best on cones (point up or down as experimentation reveals a preference) or on bearings. If you place an amp on a stand, whether thick maple, lightweight carbon fiber, etc., between cones or bearings and the amp itself, or double isolate with cones or bearing under the stand and another set under the amp, you still have a path for dissipation of energy not converted to heat, to a ground. Sorbothane does the worst of both isolation and providing a path to mechanical ground.Why, in theory, could that be? If a tube amp is sitting between the speakers on Sorbothane, what is the Sorbothane doing, possibly, other than converting vibration into heat before the vibration rattles the tubes, no? How can that not be unambiguously good?

I've had many turntables but a constant for over 40 years has been Luxman's PD444 direct drive. Luxman was ahead of their time in thinking through this turntable. Aside from the exceptional motor (custom made for Luxman by Tokyo Electric) the plinth is a sandwich of heavy iron plate on the bottom, chipboard (not MDF) in the middle, aluminum on top. The sandwich is clamped together the bolts that go through the iron and chipboard, threading into the aluminum top. The motor is bolted into an iron ring mated into the aluminum top. The iron provides mass and much less intrinsic ringing than steel. The clamped chipboard damps any ringing. The Aluminum assures resonance transmittal dissimilarities between the two metals in the sandwich. The whole thing was factory equipped with '70s thinking leveling posts with foam-damped springs and a flat circular foot. The springs were tuned and damped for insulation from floor effects but not isolation -- i.e. not floppy like a Linn or Thorens suspension of the day. Each Luxman 444 weighs about 65 lbs.

Depending on where I lived, rack requirements changed many times. In 2009 I decided it was time to get serious about racking my gear again and the layout of both of my systems' rooms argued for a low, wide arrangement, which also works well in earthquake country. I had two tables made. 30"d x 72"w x 18" high. The top of each is laminated rock maple boards, laid with opposing grains in two layers. Each board composed of the minimum number of pieces and 1.75" thick for a total top surface thickness of 3.5". Each corner has a mortised 2" x 2" post as a leg. There is a second lower shelf 1.75" thick solid rock maple set in at each leg. Each table weighs 225 lbs.

I experimented with footers and settled on 1lb. adjustable brass cones that rest points-down into Herbie's Audio Labs cone-spike Decoupling Glider. Each of these is a sandwich of teflon-like floor glide material, a middle layer of Herbie's dbNeutralizer and set into that is a cone/spike receptor of titanium, brass or steel, your choice for tuning purposes. The tables sit on the brass interface.

Sources, preamp and one of th isolation transformers are on these low racks. The turntable is centered on the top surface as are pre or TVC and phono preamps. All were improved by the new tables and the footing scheme. Power amps are always monos on the floor, not in the racks.

In 2010, I had a month of downtime between professional projects and turned my attention back to turntables. The Luxmans always earned their places in my 2 systems but I began to think that the new renaissance in turntables probably made it a good time to replace them. After narrowing down from a broad investigation, I was seriously considering getting a Brinkmann DD and a 47 Labs Koma with Tsrube arm. The combination would have cost me about $30K then so before writing those checks I pondered whether there was any more potential to be unlocked from the Luxmans. The motors were still accurate and quiet. Everything about the table was well thought out. I focused attention on the feet, which I was sure were the limiting factor.

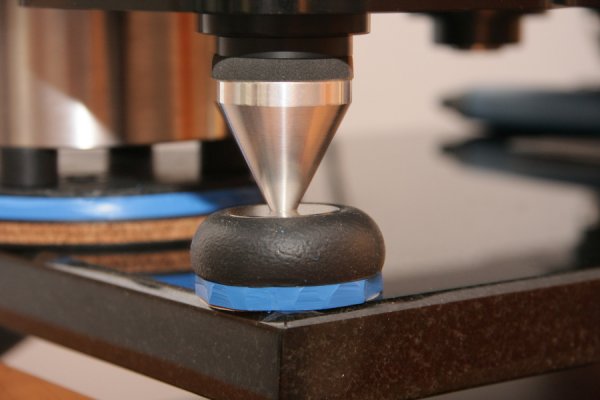

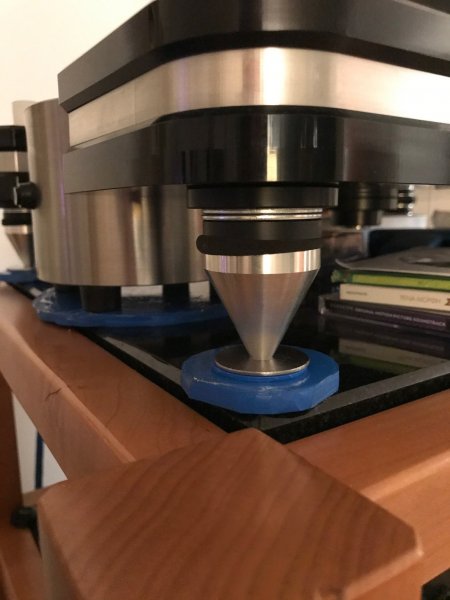

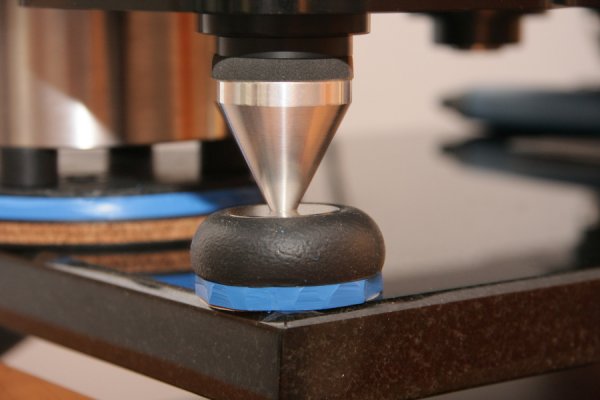

I am in a concrete slab house, so with no footfall problems to compensate for I immediately decided to ditch the spring feet altogether. and go solid. 16 bolts and off they came. Now what? I gathered a wide range of possible materials and pieces to experiment with support, including ebony + maple laminated blocks, Delrin, brass cones, aluminum cones, hard rubber, bearings, etc. I don't remember the full spectrum of what I gathered. For two solid weeks I made and installed alternatives and listened. I had, obviously, ruled out any role for Sorbothane! Every combination was better than the factory feet, by a mile. The Luxman lit up with explosive dynamics, more detail retrieval, much more spatial projection, deeper more defined bass, better texture revealed up and down the octaves range. Any note generated by anything became more harmonically complete. Still there were differences in devices and by the end of that month I settled on a winner. Same 1 pound brass cones mounted to the TT points down, attached to the underside of the Luxman's iron plate base with Herbie's thin Grungebuster elastomer (double sided adhesive). The Grungebuster material is an elastomer but it doesn't compress. So it attenuates mechanical energy but doesn't break the path to mechanical ground. I used solid brass cone point receptors under the TT, interfaced directly with the maple rack top. I thought I could get still more. At the time you could still get Aurios Media Bearings. These were originally developed to sit under electron microscope tables or other very high precision instruments, but the owner of the company was an audiophile and found years before that his gear sounded better on his bearings. I put an Aurios bearing under each cone point receptor and at that point, it all snapped into focus. The last bit of direct drive hardness was removed from the analog sound. Musicality mushroomed. My work was done. In retrospect, I think any of the non-sprung trials would have done fine on Aurios and I consider them the greater contributor to the end result.

By the way, I got more Aurios bearings and found them equally helpful under DACs and disc players. The Aurios company is gone now, and there are many more exotic items that do essentially what my Grungebuster-brass cones-receptors-bearings stack accomplishes, at much higher cost. Maybe the Nordost items in the ilk are even better. I haven't bothered to investigate that so far. There's only so much time for futzing. But now it's 12 years later and I still haven't spent that $30K+, though I know what I'll get when one or both of my Luxmans die. Now it's over 40 years for both and I don't count the days waiting.

There are a lot of devices in hifi that have untapped or closeted potential. And the solutions aren't always expensive. Some of my amps have ebony cones with brass points into ebony point receptors between amp chassis and floor; some are just fine on their native feet. I do use the old VPI Magic Bricks on my amps, which are variously slightly advantageous to clearly helpful, depending on the amp in question. Your existing gear is likely better than you think it is. Resting surfaces and thinking through mechanical grounding and insulation/isolation are worth figuring out.

Phil

Last edited:

I didn't.I wouldn't jump to the assumption that everything that sounds right is because energy transfers better into it.

One issue with amplifiers, whether SS or Valve, is that they generate their own resonances and most are built into a metal chassis that is far from dead to begin with. Tube amps, especially something like an 845 with relatively high current thoriated filament and 1200v B+ send generated energy into the chassis, and unless the power and output transformers are heavily potted, you have mechanical resonances emanating from those sources. Even if potted there are some. Sorbothane breaks the mechanical grounding. It will damp some resonance that makes it to the feet or bottom of the chassis, but you are isolating that component from a path to drain resonance out of the unit. Meanwhile you are partially isolating the amp from floor-carried vibration, but selectively. Sorbothane seems to me much less effective at low frequency isolation than highs, net result being that the amp is still disturbed by low frequency resonance which further complicates the problem of getting mechanical resonance out of the amp. Amps of any type generally sound best on cones (point up or down as experimentation reveals a preference) or on bearings. If you place an amp on a stand, whether thick maple, lightweight carbon fiber, etc., between cones or bearings and the amp itself, or double isolate with cones or bearing under the stand and another set under the amp, you still have a path for dissipation of energy not converted to heat, to a ground. Sorbothane does the worst of both isolation and providing a path to mechanical ground.

I've had many turntables but a constant for over 40 years has been Luxman's PD444 direct drive. Luxman was ahead of their time in thinking through this turntable. Aside from the exceptional motor (custom made for Luxman by Tokyo Electric) the plinth is a sandwich of heavy iron plate on the bottom, chipboard (not MDF) in the middle, aluminum on top. The sandwich is clamped together the bolts that go through the iron and particleboard, threading into the aluminum top. The motor is bolted into an iron ring mated into the aluminum top. The iron provides mass and much less intrinsic ringing than steel. The clamped particleboard damps any ringing. The Aluminum assures resonance transmittal dissimilarities between the two metals in the sandwich. The whole thing was factory equipped with '70s thinking leveling posts with foam-damped springs and a flat circular foot. The springs were tuned and damped for insulation from floor effects but not isolation -- i.e. not floppy like a Linn or Thorens suspension of the day. Each Luxman 444 weighs about 65 lbs.

Depending on where I lived, rack requirements changed many times. In 2009 I decided it was time to get serious about racking my gear again and the layout of both of my systems' rooms argued for a low, wide arrangement, which also works well in earthquake country. I had two tables made. 30"d x 72"w x 18" high. The top of each is laminated rock maple boards, laid with opposing grains in two layers. Each board composed of the minimum number of pieces and 1.75" thick for a total top surface thickness of 3.5". Each corner has a mortised 2" x 2" post as a leg. There is a second lower shelf 1.75" thick solid rock maple set in at each leg. Each table weighs 225 lbs.

I experimented with footers and settled on 1lb. adjustable brass cones that rest points-down into Herbie's Audio Labs cone-spike Decoupling Glider. Each of these is a sandwich of teflon-like floor glide material, a middle layer of Herbie's dbNeutralizer and set into that is a cone/spike receptor of titanium, brass or steel, your choice for tuning purposes. The tables sit on the brass interface.

Sources, preamp and one of th isolation transformers are on these low racks. The turntable is centered on the top surface as are pre or TVC and phono preamps. All were improved by the new tables and the footing scheme. Power amps are always monos on the floor, not in the racks.

In 2010, I had a month of downtime between professional projects and turned my attention back to turntables. The Luxmans always earned their places in my 2 systems but I began to think that the new renaissance in turntables probably made it a good time to replace them. After narrowing down from a broad investigation, I was seriously considering getting a Brinkmann DD and a 47 Labs Koma with Tsrube arm. The combination would have cost me about $30K then so before writing those checks I pondered whether there was any more potential to be unlocked from the Luxmans. The motors were still accurate and quiet. Everything about the table was well thought out. I focused attention on the feet, which I was sure were the limiting factor.

I am in a concrete slab house, so with no footfall problems to compensate for I immediately decided to ditch the spring feet altogether. and go solid. 16 bolts and off they came. Now what? I gathered a wide range of possible materials and pieces to experiment with support, including ebony + maple laminated blocks, Delrin, brass cones, aluminum cones, hard rubber, bearings, etc. I don't remember the full spectrum of what I gathered. For two solid weeks I made and installed alternatives and listened. I had, obviously, ruled out any role for Sorbothane! Every combination was better than the factory feet, by a mile. The Luxman lit up with explosive dynamics, more detail retrieval, much more spatial projection, deeper more defined bass, better texture revealed up and down the octaves range. Any note generated by anything became more harmonically complete. Still there were differences in devices and by the end of that month I settled on a winner. Same 1 pound brass cones mounted to the TT points down, attached to the underside of the Luxman's iron plate base with Herbie's thin Grungebuster elastomer (double sided adhesive). The Grungebuster material is an elastomer but it doesn't compress. So it attenuates mechanical energy but doesn't break the path to mechanical ground. I used solid brass cone point receptors under the TT, interfaced directly with the maple rack top. I thought I could get still more. At the time you could still get Aurios Media Bearings. These were originally developed to sit under electron microscope tables or other very high precision instruments, but the owner of the company was an audiophile and found years before that his gear sounded better on his bearings. I put an Aurios bearing under each cone point receptor and at that point, it all snapped into focus. The last bit of direct drive hardness was removed from the analog sound. Musicality mushroomed. My work was done. In retrospect, I think any of the non-sprung trials would have done fine on Aurios and I consider them the greater contributor to the end result.

By the way, I got more Aurios bearings and found them equally helpful under DACs and disc players. The Aurios company is gone now, and there are many more exotic items that do essentially what my Grungebuster-brass cones-receptors-bearings stack accomplishes, at much higher cost. Maybe the Nordost items in the ilk are even better. I haven't bothered to investigate that so far. There's only so much time for futzing. But now it's 12 years later and I still haven't spent that $30K+, though I know what I'll get when one or both of my Luxmans die. Now it's over 40 years for both and I don't count the days waiting.

There are a lot of devices in hifi that have untapped or closeted potential. And the solutions aren't always expensive. Some of my amps have ebony cones with brass points into ebony point receptors between amp chassis and floor; some are just fine on their native feet. I do use the old VPI Magic Bricks on my amps, which are variously slightly advantageous to clearly helpful, depending on the amp in question. Your existing gear is likely better than you think it is. Resting surfaces and thinking through mechanical grounding and insulation/isolation are worth figuring out.

Phil

Thank you, Phil, for this very interesting chronology of the evolution of your thinking and experimentation on this subject!

For 200 pound, tower-style, tube amplifiers with native rubber feet, how would you suggest they be placed on the listening room floor (wood flooring over concrete slab)?

Last edited:

Here's a simple A/B I have done using my VPI feet. Top: original configuration, Sorbothane sandwiched between Isodamp (thin and thick layers; hard to see the thin layer, but easier in the bottom picture). Bottom: just thin and thick Isodamp layers. Also notice the motor.

The difference with a simple finger tap anywhere is staggering, and much cleaner without the Sorbothane. With it, there is a thick thump, typical of its resonant properties; without it, it is barely audible at loud listening levels. During playback, Sorbothane adds quite a bit of mid-bass thickness which was really annoying. Bass performance has been so much cleaner and articulate without it. Just not suitable for audio applications, in my mind.

The difference with a simple finger tap anywhere is staggering, and much cleaner without the Sorbothane. With it, there is a thick thump, typical of its resonant properties; without it, it is barely audible at loud listening levels. During playback, Sorbothane adds quite a bit of mid-bass thickness which was really annoying. Bass performance has been so much cleaner and articulate without it. Just not suitable for audio applications, in my mind.

Okay! You win! No Sorbothane anywhere!

(Except under the feet of the refrigerator and the dishwashing machine.)

I am still going to place the Aesthetix Io control unit (which is festooned with tubes) on the Herzan/Taiko Tana.

(Except under the feet of the refrigerator and the dishwashing machine.)

I am still going to place the Aesthetix Io control unit (which is festooned with tubes) on the Herzan/Taiko Tana.

Ron,Thank you, Phil, for this very interesting chronology of the evolution of your thinking and experimentation on this subject!

For 200 pound, tower-style, tube amplifiers with native rubber feet, how would you suggest they be placed on the listening room floor (wood flooring over concrete slab)?

Based on the email alert I got about your response, I'll answer the question you originally asked plus the one you replaced that with in your edit.

Your initial question was whether I put my amps on the floor or use an intermediate platform. I used intermediate amp stands (maple) at times in the past. That didn't make an actionable difference in my current house. 20 years ago in a different house with amps on a tile floor over concrete slab, I preferred an intermediate surface (maple). My room has engineered wood on a ply base on concrete slab, so in this situation the intermediate stand isn't needed sonically. I am doing a lot of amp switching right now, during my circuits trials so I'm just using the amps on the floor, once I settle on a main amps pair I will do what I have done with my Quad II Jubilees, which is to install ebony cone point receptors on the bottom of the amps and rest the amps on ebony cones with brass tips, points up. That seems a universally effective arrangement with all my relatively low power tube amps, and it works with the M2tech Crosbys.

My Audion Black Shadow SET and Golden Dream PSET amps had very flexy, soft feet that do not feel exactly like Sorbothane. Similar but less mushy and far less sticky. The amps sounded fine as-is but I did wake them up further using inverted cones under the chassis.

200 Lbs. tetrode or pentode amps with massive transformers will need a more robust cone than what I use under my lighter-weight amps. That's where I think something more massive like the 1 lbs. brass cones used at various places in my systems, or the Mapleshade brass cones or 3 points cylinders would be great. I would experiment with whether points down or points up is better with your heavy amps and use Grungebuster discs on the flat interface whether that's at the floor or at the underside of the amp. Then there would be the matter of what cone receptor to use. For 200lbs. I'd probably recommend the mixed-material receptor I use under my 225 lbs. tables/racks.

If you like spending more money than absolutely necessary there are a bunch of other cone/bearing integrated items like from Nordost and several German companies worth considering. I would also explore getting a bearings under the cones if points, with those amps. When you get closer to solving the problem I'm happy to help onsite and come up with a specific prescription. One thing to keep in mind is that not all woods over concrete slabs behave identically in terms of energy transfer from adjacent speakers. So I'd have to examine exactly what your floor surface is an how it behaves. Solid wood flooring on an underlayment over concrete, e.g. bamboo, might require some materials-tuning to my approach, compared to what's necessary in my specific situation. It could be that in your situation an intermediate surface would be helpful, and maybe even with a different mix of cones and receptors between the amps and that intermediate surface than between the intermediate surface and the floor. But I try to keep is simple as possible.

The VPI Magic Bricks had two claims associated with them. One was that the laminated steel block encased in wood would draw stray magnetic fields to them and reduce radiated electromagnetic energy. That's always been difficult to prove in any practical sense. The other was that having done that, the mass loading especially over power transformers would be beneficial, and that claim is easily discernible. My point in bringing this up is that while you can forage for used VPI Bricks on eBay, if you ignore the EMF claim, other forms of mass loading to make the footing arrangement more effective can be found. But for an amp already weighing 200 lbs., I don't think more mass loading will be useful unless you have mechanically buzzing transformers in those behemoths.

Phil

Last edited:

Ron,

Based on the email alert I got about your response, I'll answer the question you originally asked plus the one your replaced that with in your edit.

Your initial question was whether I put my amps on the floor or use an intermediate platform. I used intermediate amp stands (maple) at times in the past. That didn't make an actionable difference in my current house. 20 years ago in a different house with amps on a tile floor over concrete slab, I preferred an intermediate surface (maple). My room has engineered wood on a ply base on concrete slab, so in this situation the intermediate stand isn't needed sonically. I am doing a lot of amp switching right now, during my circuits trials so I'm just using the amps on the floor, once I settle on a main amps pair I will do what I have done with my Quad II Jubilees, which is to install ebony cone point receptors on the bottom of the amps and rest the amps on ebony cones with brass tips, points up. That seems a universally effective arrangement with all my relatively low power tube amps, and it works with the M2tech Crosbys.

My Audion Black Shadow SET and Golden Dream PSET amps had very flexy, soft feet that do not feel exactly like Sorbothane. Similar but less mushy and far less sticky. The amps sounded fine as-is but I did wake them up further using inverted cones under the chassis.

200 Lbs. tetrode or pentode amps with massive transformers will need a more robust cone than what I use under my lighter-weight amps. That's where I think something more massive like the 1 lbs. brass cones used at various places in my systems, or the Mapleshade brass cones or 3 points cylinders would be great. I would experiment with whether points down or points up is better with your heavy amps and use Grungebuster discs on the flat interface whether that's at the floor or at the underside of the amp. Then there would be the matter of what cone receptor to use. For 200lbs. I'd probably recommend the mixed-material receptor I use under my 225 lbs. tables/racks.

If you like spending more money than absolutely necessary there are a bunch of other cone/bearing integrated items like from Nordost and several German companies worth considering. I would also explore getting a bearings under the cones if points, with those amps. When you get closer to solving the problem I'm happy to help onsite and come up with a specific prescription. One thing to keep in mind is that not all woods over concrete slabs behave identically in terms of energy transfer from adjacent speakers. So I'd have to examine exactly what your floor surface is an how it behaves. Solid wood flooring on an underlayment over concrete, e.g. bamboo, might require some materials-tuning to my approach, compared to what's necessary in my specific situation. It could be that in your situation an intermediate surface would be helpful, and maybe even with a different mix of cones and receptors between the amps and that intermediate surface than between the intermediate surface and the floor. But I try to keep is simple as possible.

The VPI Magic Bricks had two claims associated with them. One was that the laminated steel block encased in wood would draw stray magnetic fields to them and reduce radiated electromagnetic energy. That's always been difficult to prove in any practical sense. The other was that having done that, the mass loading especially over power transformers would be beneficial, and that claim is easily discernible. My point in bringing this up is that while you can forage for used VPI Bricks on eBay, if you ignore the EMF claim, other forms of mass loading to make the footing arrangement more effective can be found. But for an amp already weighing 200 lbs., I don't think more mass loading will be useful unless you have mechanically buzzing transformers in those behemoths.

Phil

Thank you very, very much Phil! When the time comes I will look forward to your on-site prescription (even though I know you don't cared for massed push-pull tube amps)!

Whatever you have, I will still help it sound best. -PhilThank you very, very much Phil! When the time comes I will look forward to your on-site prescription (even though I know you don't cared for massed push-pull tube amps)!

Whatever you have, I will still help it sound best. -Phil

Very kind of you. Thank you.

I don't know the resonance and isolation properties of Sorbothane. Perhaps this material is inefficient at transferring mechanical energy to heat.

According to Sorbothane: "Sorbothane® can absorb over 50% of the vibration energy over most of its temperature operating range at frequencies from 10 to 30,000 Hertz."

In my case, those stainless steel plates seem to be damped by directly sitting on the plywood shelves and don't sound nearly as good as when raised on rubber O rings. This seems to raise the resonant frequency when tapped by a finger or metal stick, but they don't ring per se, and certainly not perceptively when not agitated. I think it is about finding a balance and fine-tuning for the result one wants.

When you put one thing (material) on top of another, the resonance frequency of each changes. Fairly straightforward for a steel plate. For something as intricate as a component, the resonance frequency of its interior parts can change. Combination possibilities can be endless. Understanding the physical characteristics and how materials operate together is one thing; gauging sonic effects in advance of experience across various alternatives is something else altogether. Taking the DIY approach (finding a balance and fine-tuning - customizing if you will) is definitely about trial and error. Maybe that's why I'm leary of universally applied opprobriums as found in this thread.

Your experiments are interesting. You might further fine tune with O-rings of different composition and size, then again that might be mad.

Your experiments are interesting. You might further fine tune with O-rings of different composition and size, then again that might be mad.

Thank you Tim. It’s always satisfying to make progress and that’s why some people consider this pursuit a hobby. The only thing you need is effort and time and a willingness to learn. It certainly doesn’t cost much. Madness is subjective.

Incredible how much dynamics there is in this tread. Never expected to be this an big issue and so many of you actually trying a lot of things.

Never expected to be this an big issue and so many of you actually trying a lot of things.

So much information I have problems sorting it in my head, because this is quite new to me.

What I can tell so far is that Sorbothane is out What I indeed didn't like about Sorbothane is that it isn't realy stable over time.

What I indeed didn't like about Sorbothane is that it isn't realy stable over time.

What I can also tell is that it is very important to use different materials. So use a mix of hard, dense and softer material. This is called "constrained layer design CLD ?

I remember I read a test of a turntable somewhere in the 90ies, think it was about the Townshend Rock Reference (not sure though) where it was said that a lot of research went into the use of combinations of materials (now knowing what Townshend knows about supports)

What I remembered, is that it is not only the use of different materials, but also in which way they are layed out.

Here comes acoustic impedance into place and how soundwaves transfers through the materials. (@Folsom ) The part of acoustic reflexions on the edges of the adjacent materials was also a big part of that research.

A lot of thinking is to be done and you are all very helpfull in this.

Slate is the thing I allways wondered about. Although slate is a layered material in itself, it can be good. But when slapping it, my feeling says something else. With granite, even worse. Looking at the Peak Hifi SMD Acoustics plinths, these are more expensive than the SMD Acoustics Quartz plinth.

Quartz can be very good in my view as it consists of infinite little grains.

Someone with experience on the SMD Acoustic plinths? Or a link to it, could't find anything in the google...

@jeffrey_t do you have a link to the slate plinth?

Is Quartz Stone the same as Corian?

There is a lot of praise for Isodamp. Where to get it in Europe? I've only found a supplier in Norway. As I'm in Germany, maybe something a bit closer would be cool.

@Ovenmitt Yes it was your thread that initiated PeterA and me to start here. You have build such incredible pieces and unbelievable how much love in the details. You also tried different woods and their sounds. Thanx for all your input!

You find that bamboo works very good for you. That would also be great for me, as it is so easy to make it myself and don't have to supply it from somewhere.

Soapstone is also a nice material, could be good also.

Your seperate armpots make it also great to use different arms without changing the turntable with every change.

Would love to see more of what your findings will be!

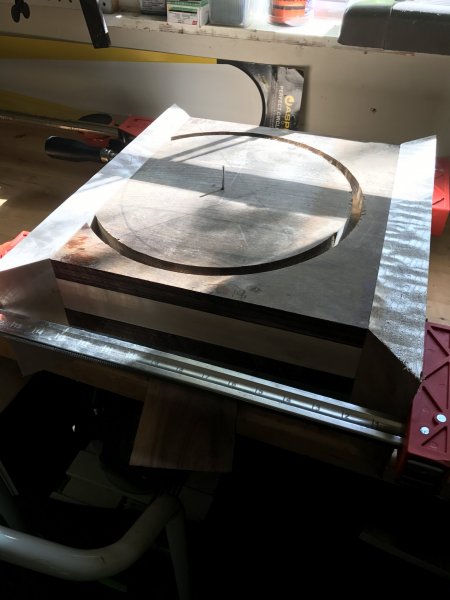

Great pics, so one can see the multiply, mapleblock, steel plate, build on a profile. Are these materials glued together?

So theres a lot of thinking and experimenting coming to us. And maybe some links as to where to get these specific materials all over the world. I would love to get my materials from Europe.

As I actually listen to my system most of the time, I like some experiment, but this shouldn't be the biggest part of my life ;-)

I'm getting aware of something that happened lately: I build my own pre amp on basis of the Calvin Buffer (DIYaudio), Shunt PreReg, Muses Volume Control and big linear PSU. I had build it in a cardbord box and sounded incredible. I than build it in a good case in aluminium and it was more quiet and no hum at all, but it did sound quite different (not so good anymore)! I will use the knowledge from here to fine tune the sound from my pre amp.

Regards,

Remco

So much information I have problems sorting it in my head, because this is quite new to me.

What I can tell so far is that Sorbothane is out

What I can also tell is that it is very important to use different materials. So use a mix of hard, dense and softer material. This is called "constrained layer design CLD ?

I remember I read a test of a turntable somewhere in the 90ies, think it was about the Townshend Rock Reference (not sure though) where it was said that a lot of research went into the use of combinations of materials (now knowing what Townshend knows about supports)

What I remembered, is that it is not only the use of different materials, but also in which way they are layed out.

Here comes acoustic impedance into place and how soundwaves transfers through the materials. (@Folsom ) The part of acoustic reflexions on the edges of the adjacent materials was also a big part of that research.

A lot of thinking is to be done and you are all very helpfull in this.

Slate is the thing I allways wondered about. Although slate is a layered material in itself, it can be good. But when slapping it, my feeling says something else. With granite, even worse. Looking at the Peak Hifi SMD Acoustics plinths, these are more expensive than the SMD Acoustics Quartz plinth.

Quartz can be very good in my view as it consists of infinite little grains.

Someone with experience on the SMD Acoustic plinths? Or a link to it, could't find anything in the google...

@jeffrey_t do you have a link to the slate plinth?

Is Quartz Stone the same as Corian?

There is a lot of praise for Isodamp. Where to get it in Europe? I've only found a supplier in Norway. As I'm in Germany, maybe something a bit closer would be cool.

@Ovenmitt Yes it was your thread that initiated PeterA and me to start here. You have build such incredible pieces and unbelievable how much love in the details. You also tried different woods and their sounds. Thanx for all your input!

You find that bamboo works very good for you. That would also be great for me, as it is so easy to make it myself and don't have to supply it from somewhere.

Soapstone is also a nice material, could be good also.

Your seperate armpots make it also great to use different arms without changing the turntable with every change.

Would love to see more of what your findings will be!

Great pics, so one can see the multiply, mapleblock, steel plate, build on a profile. Are these materials glued together?

So theres a lot of thinking and experimenting coming to us. And maybe some links as to where to get these specific materials all over the world. I would love to get my materials from Europe.

As I actually listen to my system most of the time, I like some experiment, but this shouldn't be the biggest part of my life ;-)

I'm getting aware of something that happened lately: I build my own pre amp on basis of the Calvin Buffer (DIYaudio), Shunt PreReg, Muses Volume Control and big linear PSU. I had build it in a cardbord box and sounded incredible. I than build it in a good case in aluminium and it was more quiet and no hum at all, but it did sound quite different (not so good anymore)! I will use the knowledge from here to fine tune the sound from my pre amp.

Regards,

Remco

How easy is it to cut 0.5" or 1" thick Isodamp? I'd really like to buy sheets of it and cut it to size to mate w mass loading to act as damping plates on top of gear chassis'.

It'll be a post-Covid era experiment versus alternatives of HRS Damping Plates, Herbies Supersonic Stabilisers, and a new to the market prototype tungsten-based damper I might trial.

It'll be a post-Covid era experiment versus alternatives of HRS Damping Plates, Herbies Supersonic Stabilisers, and a new to the market prototype tungsten-based damper I might trial.

Just thought I would add something to this thread myself, recently I had a custom built stand fabricated by a local guy and designed by myself for the purpose of supporting my Lenco or Spacedeck. The stand weighs currently 60kg and when the legs are filled with sand will weigh 80kg, its 500mm high x 400 deep x 520 wide, all the shelves are made from 6mm mild steel including the top plate.

Ive been doing some tests first playing the Lenco situated on footers direcrtly onto the steel plate, then I put the Lenco onto the MDF plinth from the spacedeck and then finally put the Spacedeck onto the plinth situated onto the 6mm plate separated by footers to act as a de coupler.

In all tests I have seen a marked improvement is SQ, the bass is tighter and so is the imaging although the Lenco situated onto the Spacedeck MDF plinth was not as good as sitting onto the 6mm plate, the MDF with the Lenco did have an affect of bass degradation and a certain muddiness to the sound.

The Spacedeck with the FR64s arm performed really well on the stand, probably the best I've ever heard it sound in my system.

My intention was to finish the rack with either 40mm beech or 40mm oak shelving but Im unsure now which way to go. The top plate does have 4 number holes positioned in the corners with 10mm threads so that I could use some sort of decoupling device similar to Artesina racks from Spain to separate the wooden top plate if need be, I could also get a 10mm plate cut on the laser and have this as a decoupled option however this would be mild steel and not stainless steel.

Would decoupling the top shelf add anything to what I have already designed?

Lee

Untitled by henleymajor, on Flickr

Untitled by henleymajor, on Flickr

Untitled by henleymajor, on Flickr

Untitled by henleymajor, on Flickr

Ive been doing some tests first playing the Lenco situated on footers direcrtly onto the steel plate, then I put the Lenco onto the MDF plinth from the spacedeck and then finally put the Spacedeck onto the plinth situated onto the 6mm plate separated by footers to act as a de coupler.

In all tests I have seen a marked improvement is SQ, the bass is tighter and so is the imaging although the Lenco situated onto the Spacedeck MDF plinth was not as good as sitting onto the 6mm plate, the MDF with the Lenco did have an affect of bass degradation and a certain muddiness to the sound.

The Spacedeck with the FR64s arm performed really well on the stand, probably the best I've ever heard it sound in my system.

My intention was to finish the rack with either 40mm beech or 40mm oak shelving but Im unsure now which way to go. The top plate does have 4 number holes positioned in the corners with 10mm threads so that I could use some sort of decoupling device similar to Artesina racks from Spain to separate the wooden top plate if need be, I could also get a 10mm plate cut on the laser and have this as a decoupled option however this would be mild steel and not stainless steel.

Would decoupling the top shelf add anything to what I have already designed?

Lee

Untitled by henleymajor, on Flickr

Untitled by henleymajor, on Flickr Untitled by henleymajor, on Flickr

Untitled by henleymajor, on FlickrHow easy is it to cut 0.5" or 1" thick Isodamp? I'd really like to buy sheets of it and cut it to size to mate w mass loading to act as damping plates on top of gear chassis'.

It'll be a post-Covid era experiment versus alternatives of HRS Damping Plates, Herbies Supersonic Stabilisers, and a new to the market prototype tungsten-based damper I might trial.

I can only tell you that cutting 0.25" thick is very easy, with kitchen shears or razor. I suspect 0.5 1.0" will be more challenging, but it can be done. Or you can stack up 0.25" pieces

Sure Ack. You said you'd be concerned what material one would use to mass load it as a way to chassis damp on top of gear.

But why? If it's good at damping chassis vibns from underneath, it'll surely be good at negating what's loaded on top of it?

My idea would be for 0.5" or 1" thick Isodamp w ceramic tiles on top.

But why? If it's good at damping chassis vibns from underneath, it'll surely be good at negating what's loaded on top of it?

My idea would be for 0.5" or 1" thick Isodamp w ceramic tiles on top.

Similar threads

- Replies

- 0

- Views

- 248

- Replies

- 16

- Views

- 2K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |