"Absorb" can mean different things. When mechanical energy is applied, *how* is it absorbed by Sorbothane? I.e. the Sorbothane must react in some way: maybe it bounces and oscillates at a particular frequency or maybe it converts to thermal energy. Probably some of both. But it doesn't simply destroy the applied energy, which "absorb" may imply to some people. One thing I've observed is that Sorothane doesn't pass simple finger tap tests. The other being that whatever it does, the result isn't pleasing to the ears in audio applications. At that point, I suppose I never concerned myself with why.According to Sorbothane: "Sorbothane® can absorb over 50% of the vibration energy over most of its temperature operating range at frequencies from 10 to 30,000 Hertz."

The Effect of Damping on Sound: Racks and Turntable Plinths

- Thread starter remdeck

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I would think Isodamp might behave differently depending on his thickness and how much it’s compressed and what kind of load is taking. Half an inch or 1 inch seems awfully thick to me, especially under a weight that will be used as a dampening plate on top of a component chassis.

Magico uses this material between its front baffle and the main box of the speaker enclosure and it is under extreme pressure from the bolts it is highly compressed.

On the other hand SME uses something very similar on the platter surface and underneath the metal chassis and there is no compression. Interestingly they do not use it under their motors or in their suspension system.

It seems the material can be very effective but I don’t know how much is known about how to use it optimally in the audio context.

Marc, why are you interested in such thick pieces?

Magico uses this material between its front baffle and the main box of the speaker enclosure and it is under extreme pressure from the bolts it is highly compressed.

On the other hand SME uses something very similar on the platter surface and underneath the metal chassis and there is no compression. Interestingly they do not use it under their motors or in their suspension system.

It seems the material can be very effective but I don’t know how much is known about how to use it optimally in the audio context.

Marc, why are you interested in such thick pieces?

Incredible how much dynamics there is in this tread.Never expected to be this an big issue and so many of you actually trying a lot of things.

So much information I have problems sorting it in my head, because this is quite new to me.

What I can tell so far is that Sorbothane is outWhat I indeed didn't like about Sorbothane is that it isn't realy stable over time.

What I can also tell is that it is very important to use different materials. So use a mix of hard, dense and softer material. This is called "constrained layer design CLD ?

I remember I read a test of a turntable somewhere in the 90ies, think it was about the Townshend Rock Reference (not sure though) where it was said that a lot of research went into the use of combinations of materials (now knowing what Townshend knows about supports)

What I remembered, is that it is not only the use of different materials, but also in which way they are layed out.

Here comes acoustic impedance into place and how soundwaves transfers through the materials. (@Folsom ) The part of acoustic reflexions on the edges of the adjacent materials was also a big part of that research.

A lot of thinking is to be done and you are all very helpfull in this.

Slate is the thing I allways wondered about. Although slate is a layered material in itself, it can be good. But when slapping it, my feeling says something else. With granite, even worse. Looking at the Peak Hifi SMD Acoustics plinths, these are more expensive than the SMD Acoustics Quartz plinth.

Quartz can be very good in my view as it consists of infinite little grains.

Someone with experience on the SMD Acoustic plinths? Or a link to it, could't find anything in the google...

@jeffrey_t do you have a link to the slate plinth?

Is Quartz Stone the same as Corian?

There is a lot of praise for Isodamp. Where to get it in Europe? I've only found a supplier in Norway. As I'm in Germany, maybe something a bit closer would be cool.

@Ovenmitt Yes it was your thread that initiated PeterA and me to start here. You have build such incredible pieces and unbelievable how much love in the details. You also tried different woods and their sounds. Thanx for all your input!

You find that bamboo works very good for you. That would also be great for me, as it is so easy to make it myself and don't have to supply it from somewhere.

Soapstone is also a nice material, could be good also.

Your seperate armpots make it also great to use different arms without changing the turntable with every change.

Would love to see more of what your findings will be!

Great pics, so one can see the multiply, mapleblock, steel plate, build on a profile. Are these materials glued together?

So theres a lot of thinking and experimenting coming to us. And maybe some links as to where to get these specific materials all over the world. I would love to get my materials from Europe.

As I actually listen to my system most of the time, I like some experiment, but this shouldn't be the biggest part of my life ;-)

I'm getting aware of something that happened lately: I build my own pre amp on basis of the Calvin Buffer (DIYaudio), Shunt PreReg, Muses Volume Control and big linear PSU. I had build it in a cardbord box and sounded incredible. I than build it in a good case in aluminium and it was more quiet and no hum at all, but it did sound quite different (not so good anymore)! I will use the knowledge from here to fine tune the sound from my pre amp.

Regards,

Remco

Here you go...

https://www.ebay.com/itm/Thorens-TD...143262?hash=item3639b11f9e:g:yLIAAOSw34FVF~OF

Oh, I'm just looking at HRS Damping Plates as the comparison. I assumed the damping elastomer used, bonded to the aircraft grade aluminium used in the plates, might be up to 0.5".I would think Isodamp might behave differently depending on his thickness and how much it’s compressed and what kind of load is taking. Half an inch or 1 inch seems awfully thick to me, especially under a weight that will be used as a dampening plate on top of a component chassis.

Magico uses this material between its front baffle and the main box of the speaker enclosure and it is under extreme pressure from the bolts it is highly compressed.

On the other hand SME uses something very similar on the platter surface and underneath the metal chassis and there is no compression. Interestingly they do not use it under their motors or in their suspension system.

It seems the material can be very effective but I don’t know how much is known about how to use it optimally in the audio context.

Marc, why are you interested in such thick pieces?

What thickness would you recommend in conjunction w mass loading for chassis damping?

I've found a US-based supplier who can provided 0.015" thick all the way to 1" thick.

Oh, I'm just looking at HRS Damping Plates as the comparison. I assumed the damping elastomer used, bonded to the aircraft grade aluminium used in the plates, might be up to 0.5".

What thickness would you recommend in conjunction w mass loading for chassis damping?

I've found a US-based supplier who can provided 0.015" thick all the way to 1" thick.

I don’t know Marc. I suspect something thinner than a half an inch. Tasos might have a better idea. He uses the material extensively throughout his system

That's Ack. He's already got me interested. This may be the inexpensive solution I've been looking for.

Post-Covid, cheap is gonna be more critical than ever.

Post-Covid, cheap is gonna be more critical than ever.

Your seperate armpots make it also great to use different arms without changing the turntable with every change.

Would love to see more of what your findings will be!

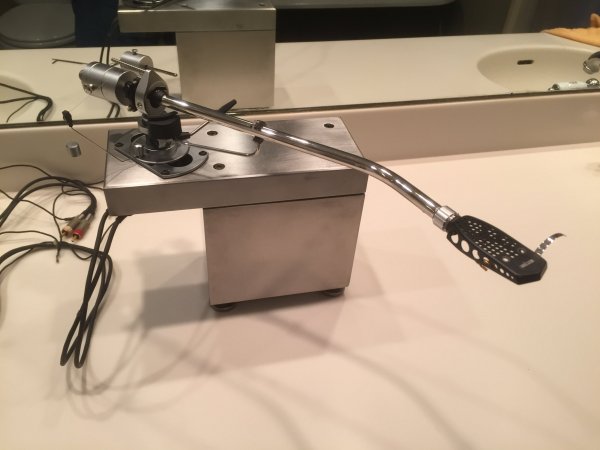

Hello Remco, I designed and had a local machine shop build for me a separate arm pod so that I could use two arms on my SME turntable. I recieved design help from member ddk. This is an all metal, high mass design which is specific to SME mounts. I have two top plates, one in stainless steel, one in brass. I have not tried the brass one yet. Here is a link to a detailed description of the design process and results:

https://www.whatsbestforum.com/thre...ct-for-sme-30-12-turntable.29517/#post-626894

It is a heavy #304 stainless steel design weighing about 40 lbs. I am very happy with the sonic results.

I'm getting aware of something that happened lately: I build my own pre amp on basis of the Calvin Buffer (DIYaudio), Shunt PreReg, Muses Volume Control and big linear PSU. I had build it in a cardbord box and sounded incredible. I than build it in a good case in aluminium and it was more quiet and no hum at all, but it did sound quite different (not so good anymore)! I will use the knowledge from here to fine tune the sound from my pre amp.

Regards,

Remco

That's pretty easily explainable, actually. It's not what you think, either

@PeterA

Magico probably uses that layer for mating surfaces, not for CLD effect. It might have a tiny bit of CLD, but the truth is it's just hard as hell to get perfectly mated surfaces together. If it was easy every car on the planet would have skipped head gaskets.

That is interesting, Folsom. I have helped replace a tweeter on one of these new Magico speakers. That layer of blue Isodamp is thin and cut in such a way that it really does resemble a gasket of some kind. It causes both surfaces to be stuck together. It must be removed very carefully and it can then be refitted carefully, and all is well.

When it was not perfectly reinstalled on a Q series speaker belonging to a friend, there was incredible air pressure leaking out from the baffle. I noticed it sounded a bit off and I ran my hand along the seam and discovered the problem. He sent the speakers back to the factory for repair and they now sit in my listening room.

@Lee Henley

Would decoupling the top shelf add anything to what I have already designed?

Without testing facility and experience it's impossible to say. For most it's a case of suck and see.

I've sat my TT plinth on blocks, various types of cones and settled on Alto Extremo Neoflex, whacking great alloy lumps incorporating adjustable magnetic levitation. The Neoflex consistently delivered a sweeter more natural presentation by comparison to other efforts. Not a lot in it but a further step in the right direction.

Isodamp is available with a pressure sensitive adhesive (PSA) option on one or both sides for a small additional cost. The PSA also helps absorb vibration. The isodamp I purchased did not come with any adhesive, however, I think it can be added after purchase. Isodamp can be purchased in thicknesses ranging from 0.015" to 1".

Magico also makes an audio rack using only aluminum, isodamp and copper. I'm assuming the copper helps dissipate heat. Each shelf ways 90 lbs.

Magico also makes an audio rack using only aluminum, isodamp and copper. I'm assuming the copper helps dissipate heat. Each shelf ways 90 lbs.

Attachments

Hello Remco, I designed and had a local machine shop build for me a separate arm pod so that I could use two arms on my SME turntable. I recieved design help from member ddk. This is an all metal, high mass design which is specific to SME mounts. I have two top plates, one in stainless steel, one in brass. I have not tried the brass one yet. Here is a link to a detailed description of the design process and results:

https://www.whatsbestforum.com/thre...ct-for-sme-30-12-turntable.29517/#post-626894

It is a heavy #304 stainless steel design weighing about 40 lbs. I am very happy with the sonic results.

View attachment 63374

View attachment 63375

Looking great, but questioning the same as to Ovenmitt : arm and platter are not on one rigid plane. This is what I know not really what it is should be (?)

Then give me some hints or actually what you thinkThat's pretty easily explainable, actually. It's not what you think, either

Marc, I suppose something like this could easily be DIY'd even cheaper, but is this the type of thing you're looking for?That's Ack. He's already got me interested. This may be the inexpensive solution I've been looking for.

Post-Covid, cheap is gonna be more critical than ever.

https://edensoundaudio.com/shop/damping-disc/

Available with Isodamp backing, under options.

Bazelio, a little pricey at $26 plus carriage/UK taxes for 2" diameter.

I'm better off buying sheets of Isodamp and cutting to size for greater area coverage.

I'm better off buying sheets of Isodamp and cutting to size for greater area coverage.

That's Ack. He's already got me interested. This may be the inexpensive solution I've been looking for.

Post-Covid, cheap is gonna be more critical than ever.

FYI all, Marc gave me an assignment! And I need to get going fast, and post here. Yessir!

Why not just buy 7075 aluminum plate stock or bar stock and adhere isodamp to it? Are the HRS plates really anything more than that?Bazelio, a little pricey at $26 plus carriage/UK taxes for 2" diameter.

I'm better off buying sheets of Isodamp and cutting to size for greater area coverage.

Similar threads

- Replies

- 4

- Views

- 745

- Replies

- 33

- Views

- 3K

- Replies

- 0

- Views

- 645

- Replies

- 16

- Views

- 3K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |