In home brew, TT & TA Air bearing 16" ... for the musical fun.

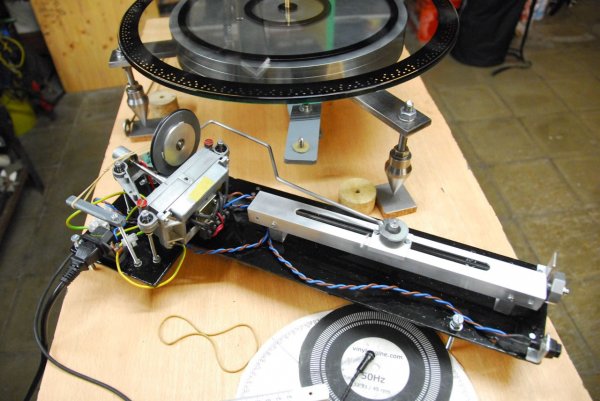

AIR BEARING TURNTABLE 16”

Concept/technical specifications:

Type: air bearing spinning platter

Nozzels: multiple air nozzels (home made)

Dynamic mass: 12kg

Turntable platter: C45 / Dia: 325mmx14,4mm

Motor management: “à la Lenco”, with micro fine tuning Turntable speed (fix): 33,3 RPM

Turntable: 16” Glasplatter 450mmx8mm

Stroboscope : 16” (à la EMT … custom home made )

Center: three points centering (near absolute center)

Air compressor: oil free air compressor

Air pressure turntable: 0,7bar (minimumminimorum)

Total weight: 45kg (appr)

Free run from 33,3 rpm to 0 rpm: total time 11minutes 45 seconds

AIR BEARING LINEAR TRACKING TONE ARM 16”

Concept/technical specifications (home made):

Type: air bearing linear tracker (à la “Terminator”). Effective lenght: 450mm (16”)

Tracking error: 0°

Pressure tone arm air pressure: 0,4bar (appr).

And my daily TT (&TA):

Technics SL220 with (home brew) air bearing TA (à la Terminator & Lyra) ...

.... It's music .... i like it ....

Karel

AIR BEARING TURNTABLE 16”

Concept/technical specifications:

Type: air bearing spinning platter

Nozzels: multiple air nozzels (home made)

Dynamic mass: 12kg

Turntable platter: C45 / Dia: 325mmx14,4mm

Motor management: “à la Lenco”, with micro fine tuning Turntable speed (fix): 33,3 RPM

Turntable: 16” Glasplatter 450mmx8mm

Stroboscope : 16” (à la EMT … custom home made )

Center: three points centering (near absolute center)

Air compressor: oil free air compressor

Air pressure turntable: 0,7bar (minimumminimorum)

Total weight: 45kg (appr)

Free run from 33,3 rpm to 0 rpm: total time 11minutes 45 seconds

AIR BEARING LINEAR TRACKING TONE ARM 16”

Concept/technical specifications (home made):

Type: air bearing linear tracker (à la “Terminator”). Effective lenght: 450mm (16”)

Tracking error: 0°

Pressure tone arm air pressure: 0,4bar (appr).

And my daily TT (&TA):

Technics SL220 with (home brew) air bearing TA (à la Terminator & Lyra) ...

.... It's music .... i like it ....

Karel