Thank you both, Kcin and micro, for taking the time to engage on this. I appreciate your help.

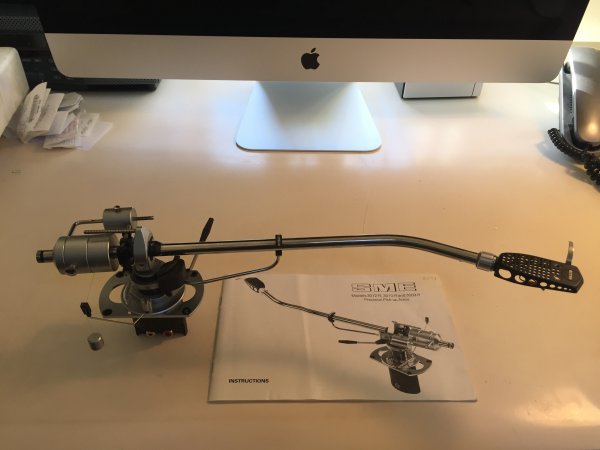

I am a member at VE and downloaded copies of the manuals and brochures they have available for the 3012R.

It's a bit of a curious situation. I wonder how much difference is due to Imperial vs. Metric units and decimal vs fractional statement of measure. And which is SME's native tongue?

The SME brochure for the 3009R/3010R/3012R states the 3012R Spindle to Bedplate center at 295.6mm / 11.638 inches. 11.638" converts to 11-41/64"

As you point out the manual has 294.1mm / 11-9/16 inches for this measurement.

11-9/16 inches converts to 293.69 mm (0.41mm shy of 294.1) and 11.56 inches.

(conversions per

this calculator.)

Difference between the brochure and manual

... in metric is 1.5mm

... in decimal inches is 0.058"

... in fractional inches is 1/16"

And, the numbers vary slightly based on which way the conversion is done, from what to what.

--> In the end (heh) how much difference does it really make? <--

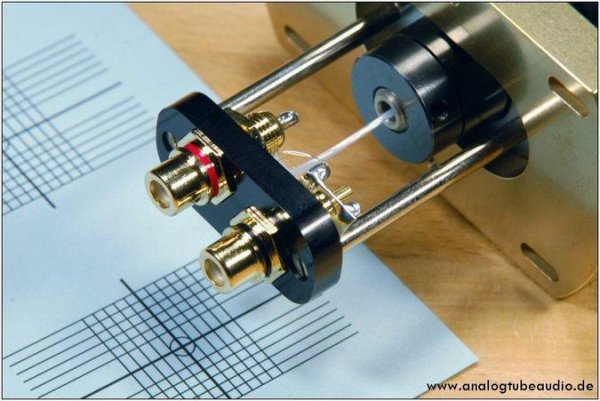

We're talking about the center point of the arm within the sled/slot and the position of the arm is not fixed there but slides back and forth. Wouldn't it be only at the very end of the slot that one could run out of room for stylus position by, eg. 1/16 of an inch?