In 120 volt circuits, I find the entire magic with grounding is attention to the branch circuit neutrals and their relation to the utility neutral and earth grounds. The return current or neutral is very sensitive to how its installed and what its terminated too. IE - Copper is king, and it must be star grounded to the utility neutral. This is more important than fuse/cable direction. Especially using all copper panels. For the price some people pay for a single QSA fuse, you could replace your loadcenter with a copper panel and realize a large sonic gain that is very apparent in its reduction of glare and haze.current flows in a loop, so in any two-terminal device such as a speaker the current that goes in must come out. If you break the loop, no current flows, so I do not see how you can say the return current can be ignored.

Fuse and Cable Directionality

- Thread starter Geoffkait

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I can't speak to "sonic gain" and such, but the rest of it is (ahem) sound advice. The safety ground is also important. One thing nobody ever does is to go back every few years and retighten all the connections in the service and inspect outlets, especially those subjected to high current depends. Just last year we had a couple of power cords attached to high-power test equipment fry (literally, they turned to charcoal) and take out a 30-A socket with them because they had gotten a little loose from repeated insertion/withdrawal cycles as we moved the equipment around the lab.In 120 volt circuits, I find the entire magic with grounding is attention to the branch circuit neutrals and their relation to the utility neutral and earth grounds. The return current or neutral is very sensitive to how its installed and what its terminated too. IE - Copper is king, and it must be star grounded to the utility neutral. This is more important than fuse/cable direction. Especially using all copper panels. For the price some people pay for a single QSA fuse, you could replace your loadcenter with a copper panel and realize a large sonic gain that is very apparent in its reduction of glare and haze.

Load balancing is also important so neither phase (side) in the panel handles too much power (current). That can cause some "interesting" weirdness, like shifting the average voltage so it is no longer zero-mean. That leads to a slight offset that appears like DC and causes transformers to buzz.

Edit: Forgot who you were and what you did for a living, preaching to the choir, sorry!

And yet the measurements are consistent for all fuses they measured. I.e., not random, not insignificant. If you had read further you would have know the third part tester is a well know company that would be able to measure small difference. I also explained earlier that the effects in listening tests are not small, that very small differences in voltage drop are a red flag, but it doesn’t mean the difference in listening to one direction vs the other is because of the voltage drop per se, which is exactly what’s in the data sheets written part. And what people hear who have purchased high end fuses. You know, 120,000 of them and counting.

Call me skeptical

When you are looking at 3 decimal places on a mili ohm it's not significant. To get repeatability on that measurement is no easy task and it can change every time you measure them.

It's in the "mud"

I have used mili ohm meters and witnessed them used to verify ground bonding stubs for contact resistance on satellite payloads. Unless your are using a 4 probe set up it really difficult to get a meaningful measurement.

More importantly any claimed differences in directional resistivity is completely swamped out in every case once you put it into the holder.

So if it's not resistance what is it? When you purchase these fuse's are they marked? And if so how they determine it will be "right" in your set up.

IME Plain Wire on a spool stranded or solid is not directional.

Rob

Last edited:

Take spool of solid thhn wire, not stranded. Cut 4 strips off that are long enough to be speaker cables. Flag the start end of each piece. All flags have to attach at the same start end. You can't use any ends such as spades or banana. Bare copper only. Insert them all the same direction. Listen. Then flip them and listen. Do this a few times. Find music that is large scale with high dynamics. Listen for intensity. One direction should be a little fuller and more harmonicly complete. The other way a little thinner and maybe sensed as faster.IME Plain Wire on a spool stranded or solid is not directional.

Rob

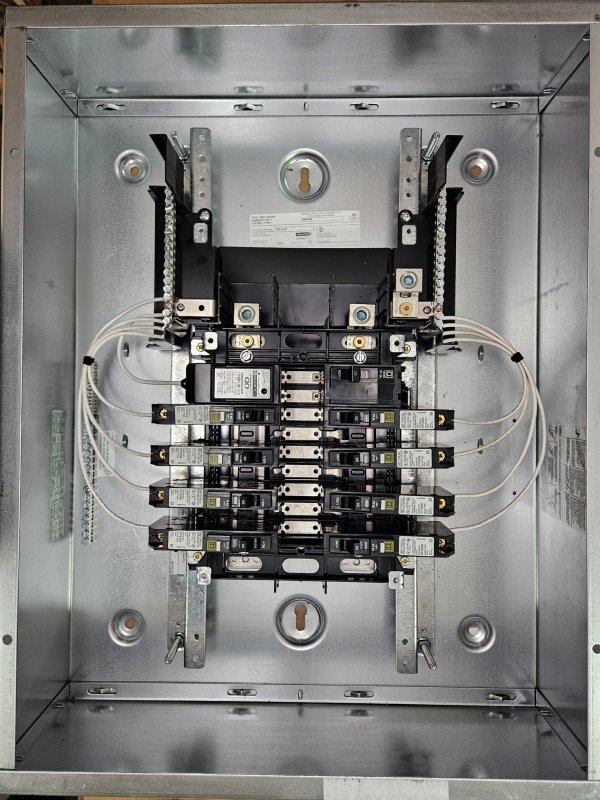

I have taken a standard Square D loadcenter and a Square D NQ panelboard that I have optimized and sources as all copper and compared them. In this image I used the isolation transformer bypass. This is just street power. I moved the feeder wire from one panel to the other. I then moved the branch wires along.with the feeder. I did not change breakers. I simply popped the breaker off the rail and moved the branch wire/breaker as a unit from panel to panel.I can't speak to "sonic gain" and such, but the rest of it is (ahem) sound advice.

My friend Bob was with me. Bob has gone to all the shows I have displayed at and worked the booth with me. Bob has a good ear and a very well tuned system and room.

We were both floored the amount of change between the panels. We equated the insertion of an all copper NQ panelboard to a magnitude of adding an isolation transformer. More quiet. Reduction in glare through the whole frequency spectrum. Removal of haze. Shockingly higher performance.

Part of what might make this happen is I break every one of these panels down to its basic parts. I polish to a bright finish every conductive surface contact face and treat with about 8 to 12 applications of various Caig Deoxit. There is 0 aluminum in these panels. The lugs you see. That is $340 for lugs only. Square D UL listed and labeled for the panel. Very hard to aquire.

My point is that I believe a fuse and wire have a grain that at times can be heard. Not all the time in every system. It's subtle. Putting a better panel into your home is very sonically apparent and will far exceed any wire or fuse directionality. It far exceeds any inwall wire you use. I would assume any fuse too. You can't mess the wiring up in these panels either. They are so well designed there are no lesser performance spaces to land a wire. But if you look close, you will see I land all neutrals right at the neutral utility crossbar.

Attachments

Thin wire not stranded? Why would I use thin wire of any type for a low impedance load where current capacity is what is required?Take spool of solid thhn wire, not stranded.

Rob

I am explaining how to listen to the grain of a wire if you don't believe you can hear it. I am not trying to tell you to use THHN/THWN as speaker wire. That is not the point.Thin wire not stranded? Why would I use thin wire of any type for a low impedance load where current capacity is what is required?

Rob

This only works with solid wire.

I have never heard stranded. I think the capacitive coupling of all the touching strands smears the sound to much. Stranded is a bit wolly and muddy. A little bass slow and heavy. When used at 120 volt branch wire. Again, this is not speaker wire. The speaker is just a tool. Use a crappy background music system. You don't need to do this with your big rig.

It might have been interesting to loosen and retighten connections on the original panel just to ensure oxidation and/or reduced contact pressure did not cause higher connection impedance that led to the sonic differences.I have taken a standard Square D loadcenter and a Square D NQ panelboard that I have optimized and sources as all copper and compared them. In this image I used the isolation transformer bypass. This is just street power. I moved the feeder wire from one panel to the other. I then moved the branch wires along.with the feeder. I did not change breakers. I simply popped the breaker off the rail and moved the branch wire/breaker as a unit from panel to panel.

My friend Bob was with me. Bob has gone to all the shows I have displayed at and worked the booth with me. Bob has a good ear and a very well tuned system and room.

We were both floored the amount of change between the panels. We equated the insertion of an all copper NQ panelboard to a magnitude of adding an isolation transformer. More quiet. Reduction in glare through the whole frequency spectrum. Removal of haze. Shockingly higher performance.

Part of what might make this happen is I break every one of these panels down to its basic parts. I polish to a bright finish every conductive surface contact face and treat with about 8 to 12 applications of various Caig Deoxit. There is 0 aluminum in these panels. The lugs you see. That is $340 for lugs only. Square D UL listed and labeled for the panel. Very hard to aquire.

My point is that I believe a fuse and wire have a grain that at times can be heard. Not all the time in every system. It's subtle. Putting a better panel into your home is very sonically apparent and will far exceed any wire or fuse directionality. It far exceeds any inwall wire you use. I would assume any fuse too. You can't mess the wiring up in these panels either. They are so well designed there are no lesser performance spaces to land a wire. But if you look close, you will see I land all neutrals right at the neutral utility crossbar.

Nice job with the panels! I think a lot of 'philes spend a lot of effort and money on things that simply mask the real issues, like issues in wall power delivery. Every now and then I, and I am sure you, have seen service panels that were an absolute mess.

The loadcenter inder test was in perfect working order. All the branch terminations were fresh. And had deoxot on them. The bus was torqued.

I have seen more panels than I care that are a mess. There are times when just reworking a panel, star grounding it and deoxing it revelas a fist pumping return. Other times its subtle to nothing. Panels corrod over time making it worse. There are a lot of Eaton BR and SqD Homeline with aluminum bus that end up with loose contacts that burn the bus and cause massive noise. Or water got in and again, massive noise. Or its by a salt water body and oxidized badly.

Far to many people treat this with a power conditioner. That is a 2 layer issue with amps. Bad power and a filter where it should not be.

I have seen more panels than I care that are a mess. There are times when just reworking a panel, star grounding it and deoxing it revelas a fist pumping return. Other times its subtle to nothing. Panels corrod over time making it worse. There are a lot of Eaton BR and SqD Homeline with aluminum bus that end up with loose contacts that burn the bus and cause massive noise. Or water got in and again, massive noise. Or its by a salt water body and oxidized badly.

Far to many people treat this with a power conditioner. That is a 2 layer issue with amps. Bad power and a filter where it should not be.

The whole Al wire panel thing was a disaster that took years to undo with copper pigtails and proper Al/Cu interfaces for service inlets and panels. I am sure there still many, many of them out there.

I had power conditioners in mind as part of the problem masking the real (underlying) issue.

Edit: We're diverging from the whole fuse directionality debate so probably a topic for another thread (bet there are already several). I suppose we could ask how many have reversed the power cables in their walls, or on the poles to the electrical utility, to see if it had a discernable effect...

I had power conditioners in mind as part of the problem masking the real (underlying) issue.

Edit: We're diverging from the whole fuse directionality debate so probably a topic for another thread (bet there are already several). I suppose we could ask how many have reversed the power cables in their walls, or on the poles to the electrical utility, to see if it had a discernable effect...

Last edited:

True on divergent.Edit: We're diverging from the whole fuse directionality debate so probably a topic for another thread (bet there are already several). I suppose we could ask how many have reversed the power cables in their walls, or on the poles to the electrical utility, to see if it had a discernable effect...

I had one customer switch the wire in the wall before final termination. He then used a digital recorder to understand the correct direction. Not a bad idea. If someone were to change the fuse in something and use a recorder with a before and after recordings, it would be easy to hear the difference as you could perform a very quick back to back listen.

More important, others could hear it to. Just upload the file. That would shut the debate down.

I am saying something better than a phone. Like a digital recorder. But if a phone captured it, that would be a very telling.

Last edited:

I have 4 pairs of duplexes with their own circuit breakers in a audio only subpanel for my listening room. All are wired with identical 10 awg copper wiring and the two being used have 4 Synergistic Research Blue duplexes. I noticed that each circuit breaker's pairs have different sound. It is possible that the wiring orientation may cause this. So, if even non metallic wire is directional, I'm sure that metallic copper wire is too and my wiring may have differing orientation. I cannot check that out as it basically permanently attached within 16" thick walls. All breakers are oriented in a line one above the other. Maybe I should have them alternate for the two that I use. The subpanel is in a moderate temperature controlled, lower humidity interior room and is 5 years old. Maybe I should change the panel to copper rather than whatever metal it is. Or maybe the breakers should be upgraded.Even 10 awg non metalic wire that goes behind your wall is directional. A customer of mine has recorded the sonic difference. I tried orienting it once. I found the ground reversed to the hot and neutral. Makes sense to me. Adding the jacked would flip the orientation of the wire to the bare copper ground.

I removed a large isolation transformer after 7 or 8 years which now I realize, choked the dynamics (the advertisement stated it has no negative affect on the sound=HA)! I replaced it with a 4 plex, star grounded, cryo and other treated duplex, CNC aluminum power distribution box. It has zero affect on the sound of the components compared to plugging them in directly into the wall duplex. Neutral sounding was what I wanted although there is no surge protection other than the fuse (my current pre-amp is fuseless and has no circuit breaker either).

Last edited:

..that means two lines are on one phase, two on the other (assuming standard US/220v installation). Does it matter? Maybe. Easy to move the breakers and listen (assuming you have enough "slack" in the hot-wire to reach the new location on the buss). Or plug gear into the two outlets on the same phase, if your cables will reach.All breakers are oriented in a line one above the other.

What do you mean different sound. How did you determine this?I have 4 pairs of duplexes with their own circuit breakers in a audio only subpanel for my listening room. All are wired with identical 10 awg copper wiring and the two being used have 4 Synergistic Research Blue duplexes. I noticed that each circuit breaker's pairs have different sound. It is possible that the wiring orientation may cause this. So, if even non metallic wire is directional, I'm sure that metallic copper wire is too and my wiring may have differing orientation. I cannot check that out as it basically permanently attached within 16" thick walls. All breakers are oriented in a line one above the other. Maybe I should have them alternate for the two that I use. The subpanel is in a moderate temperature controlled, lower humidity interior room and is 5 years old. Maybe I should change the panel to copper rather than whatever metal it is. Or maybe the breakers should be upgraded.

I removed a large isolation transformer after 7 or 8 years which now I realize, choked the dynamics (the advertisement stated it has no negative affect on the sound=HA)! I replaced it with a 4 plex, star grounded, cryo and other treated duplex, CNC aluminum power distribution box. It has zero affect on the sound of the components compared to plugging them in directly into the wall duplex. Neutral sounding was what I wanted although there is no surge protection other than the fuse (my current pre-amp is fuseless and has no circuit breaker either).

Some wire responds to being moved rather than anything to do with directionality (which seems to have more to do with the dielectrics involved than the wire itself). So when you reverse a speaker cable to see if it sounds better in one direction, you're not giving it time to settle in. About 35 years ago George Cardas made a set of microphone cables for my Neumann mics. The U67s don't use phantom power like modern mics; instead they have power supplies with multiple connections in the cable to provide for DC filament and high Voltage for the tubes in the mics. I found the Cardas mic cables were very sensitive to how they were laid out and they made a very audible sound through the speakers when you moved them. The original Neumann cables also had this problem but it was far less obvious. The Cardas cables needed several hours to settle down, which made them impractical in the studio where the mics are moved about quite a lot. IOM you are ascribing the wrong explanation to explain what you're hearing.I would agree with this. I believe my Inakustik cables are directional because the shield is terminated at one end.

I have some genesis interconnect. One end is silver and the other copper. I was told to put the copper at the source and the silver at the load. But I don't know it has anything to do with anything outside being consistent.

Something I have always pondered is this idea a wire burns in and develops a direction. Not sure this is what people mean. When I think of a piece of wire and the crystal boundaries having a grain, I can't conceive of any of that changing over time due to use. Not unless that use resulted in heat. A lot of heat.

I do agree you change the boundaries when you bend a wire. If you bend it back and forth enough times, it will snap in half. So yes you have changed the structure.

Its not to prevent a ground loop, its to prevent signal return current from passing through the shield.Food for thought.

If interconnects have arrows I would think Asside of makers advice it’s a guess but ,

If cables are terminated differently this can be understood more

in effect it to lower or eliminate a ground loop.

think like shielded data or signal wires that are shielded

only one side gets used

not both

also this Effects the capacitor and inductance

For a total imp load

IOW the shield is thus able to have far less noise in it which otherwise is in turn impinged to a small degree into the signal itself. In this way the cable is able to be a little bit more neutral. BTW if a balanced line is set up properly, this idea is used there because if the setup complies with AES48 (the balanced line standard) the shield is completely ignored by the signal; its only used for shielding unlike many RCA cables.

I'm confirming that transformer connections can result in more or less leakage (which is audible, perhaps as a buzz and measurable), but that has nothing whatsoever to do with fuse direction- its a completely different thing!!Okay, again, with my huge tube mono block tube amps, I could kill myself touching the wrong live component (the manufacturer said the same - high voltage). I'll just stick to my own method but thanks for the information. You are confirming that there exists a difference in sound of fuses based on direction.

OK, let’s look at a fuse in an audio AC circuit, for example a fuse located on one leg of the two AC wires coming into an amplifier. Visualize the signal wiggling back and forth in the fuse wire. When the signal is moving in the direction of the speakers it causes the speaker diaphragm to move out, assign the fuse is located on the + wire and cabling has consistent connectivity. But when the signal is moving in the opposite direction, I.e., away from the speakers toward the wall there is *no effect on the speakers* or the sound. We only care about the signal when it’s moving toward the speakers, you can ignore the signal moving toward the wall.

The E and B fields are produced by the electromagnetic wave in the wire. And E and B fields lie completely outside the wire or cable conductor and are what interacts with the magnet and voice coil of the speaker diaphragm, to move it in and out, + and - wires of the AC circuit.

Thus, for best results both + and - wires of power cord should be controlled for directionality, on the non-fuse leg the signal going toward the speaker also affects the sound, and the signal on the non-fuse wire can be ignored when it’s traveling toward the wall.

Rex, you of all people should be aware that audio is an AC signal, a bit more complex than that feeding a breaker box but AC nonetheless. Imagine the idea that a fuse or strand of wire were really directional. The only way it could be directional is if it conducted better in one direction as opposed to the other (somehow the resistance of the wire is different in one direction), yet we are talking about an AC signal current, which must be free to conduct equally well in both directions! If directional, a current dropped across that resistance would result in greater heat (Ohm's Law).I am explaining how to listen to the grain of a wire if you don't believe you can hear it. I am not trying to tell you to use THHN/THWN as speaker wire. That is not the point.

This only works with solid wire.

I have never heard stranded. I think the capacitive coupling of all the touching strands smears the sound to much. Stranded is a bit wolly and muddy. A little bass slow and heavy. When used at 120 volt branch wire. Again, this is not speaker wire. The speaker is just a tool. Use a crappy background music system. You don't need to do this with your big rig.

Since wires do heat in AC power applications, doesn't it make more sense (a lot simpler explanation) that its simply due to Voltage drop occurring in both directions?

Ralph, I don't claim to have technical logic behind wire directionality in AC. What I believe I hear is very subtle when it comes to orientation. Simply throwing 10 awg solid wire at your system is far more impactful than wire or fuse orientation. But I would also say, its absolutely free. Of no cost at all to flip a fuse and listen. No one should talk anyone out of attempting to tune their stereo.

I would also say, just using a decent fuse is far more impactful than the way its facing in the holder. Get a Wilmar or Hifi supreme fuse at a minimum. I have no idea if a $2000 QSA fuse is better than a $70 fuse. There is a thread for that. There are plenty of people saying its impossible for a fuse to have a voice too. And if it does, god forbid your house will burn as punishment for using it.

I would also say, just using a decent fuse is far more impactful than the way its facing in the holder. Get a Wilmar or Hifi supreme fuse at a minimum. I have no idea if a $2000 QSA fuse is better than a $70 fuse. There is a thread for that. There are plenty of people saying its impossible for a fuse to have a voice too. And if it does, god forbid your house will burn as punishment for using it.

Let me ask this Ralph

@Atmasphere

Correct me where I am wrong.

The work in an AC circuit is not in the wire. Its in the electromagnetic field that rises out of the wire.

The electrons drift in the wire while work is being done. Its only inches per second, but they move in one direction.

Magnets are loosly based on the orientation of the molecules in the metal. If you change the orientation, you weaken or strengthen the magnet.

Since elecrical work is in the electromagnetic field around a wire, is there any chance the orientation of the molecules in the wire would impact the drift of electrons as well as the way the field rises out of the wire?

@Atmasphere

Correct me where I am wrong.

The work in an AC circuit is not in the wire. Its in the electromagnetic field that rises out of the wire.

The electrons drift in the wire while work is being done. Its only inches per second, but they move in one direction.

Magnets are loosly based on the orientation of the molecules in the metal. If you change the orientation, you weaken or strengthen the magnet.

Since elecrical work is in the electromagnetic field around a wire, is there any chance the orientation of the molecules in the wire would impact the drift of electrons as well as the way the field rises out of the wire?

This is all fascinating stuff to we novices. I am definitely going to experiment with fuse direction once I receive them. I ordered four AMR fuses for switches and FMCs and one for my Zidoo media player. As @Kingrex said, it is a free tweak, so why not try. If it does nothing, I've confirmed it myself. If I think I hear a difference, that's fine too. Whatever makes us happy!

The electromagnetic field is caused by electron flow and vice versa. You can't separate them. The electrons move back and forth in the wire if its AC and may not move even an inch over time.Let me ask this Ralph

@Atmasphere

Correct me where I am wrong.

The work in an AC circuit is not in the wire. Its in the electromagnetic field that rises out of the wire.

The electrons drift in the wire while work is being done. Its only inches per second, but they move in one direction.

Magnets are loosly based on the orientation of the molecules in the metal. If you change the orientation, you weaken or strengthen the magnet.

Since elecrical work is in the electromagnetic field around a wire, is there any chance the orientation of the molecules in the wire would impact the drift of electrons as well as the way the field rises out of the wire?

Magnets are their own weird thing. Even though I had to study them a lot in school they still mess with my head. I don't think that has anything to do with this discussion.

I'm not sure the electrical work isn't in the wire since wire heats up over time if there's too much current. That heat is work being done.

Drift velocity is very, very low, see e.g. https://en.wikipedia.org/wiki/Drift_velocity -- that article lists about 23 um/s for 1 A in a copper wire. It depends upon both the current and voltage difference unless the wire is superconducting. But for AC, they move back and forth, there is essentially no net movement. Current flow (waves) is typically from 60% to 80% the speed of light in common wire and coax (can push 90~98% in RF cables). At very high frequencies, molecular orientation and other things do cause problems leading to dispersion with in the wire itself, but that is a problem for systems operating over 100 GHz, mainly in the THz region, well above the range of even the most avid audiophile's hearing (and speakers).

As for "work", there is current flow through the wire, and resistance that leads to work in the electro-thermodynamic sense (wow, rarely use that word in a sentence!), causing the wire to heat up. Normally that's deep, deep in the mud.

Like many things, marketing takes advantage of real but irrelevant science to sell all sorts of products (in every field!)

Edit: Ralph was quicker, and shorter, on the draw.

As for "work", there is current flow through the wire, and resistance that leads to work in the electro-thermodynamic sense (wow, rarely use that word in a sentence!), causing the wire to heat up. Normally that's deep, deep in the mud.

Like many things, marketing takes advantage of real but irrelevant science to sell all sorts of products (in every field!)

Edit: Ralph was quicker, and shorter, on the draw.

- Status

- Not open for further replies.

Similar threads

- Replies

- 31

- Views

- 2K

- Replies

- 6

- Views

- 2K

- Replies

- 3

- Views

- 2K

- Replies

- 242

- Views

- 23K

- Replies

- 21

- Views

- 1K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |