American Sound AS-2000 Installations- Far East (Tango)

- Thread starter ddk

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

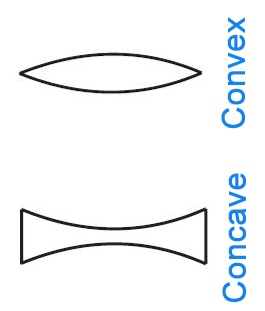

Imagine a record on a concave platter with a center weight it’s self explanatory, then a record on the convex platter.

View attachment 43829

David

a note might be that every vacuum hold down system out there uses a very slight convex shape approach to hold the platter. the rubber gasket on the outside edge is higher relative to the middle suction, and spindle area is then higher slightly. tension keeps things stable.

a note might be that every vacuum hold down system out there uses a very slight convex shape approach to hold the platter. the rubber gasket on the outside edge is higher relative to the middle suction, and spindle area is then higher slightly. tension keeps things stable.

Are you sure Mike, I never noticed the convex form in any of the Micros or the AF-1? Gotta stick an angle meter on them when I get back home and see if the platter sloped.

david

Concave works so long as the edge isnt. The edge of the LP is taller. You want to avoid supporting it because thickness varies.

Being slightly concave makes it so the LP when center weighted will more evenly press against the platter. The reason is many LP's have a tendancy to bow up ever so slightly with a center weight. Davids approach makes perfect sense, as it will couple better just as he says. With a toally flat surface you get areas more and less coupled, which can cause small resoances in the "floating" sections. It isnt the end of the world. I still have warped LP's that sound fab; but yes they could be better were they not warped.

Being slightly concave makes it so the LP when center weighted will more evenly press against the platter. The reason is many LP's have a tendancy to bow up ever so slightly with a center weight. Davids approach makes perfect sense, as it will couple better just as he says. With a toally flat surface you get areas more and less coupled, which can cause small resoances in the "floating" sections. It isnt the end of the world. I still have warped LP's that sound fab; but yes they could be better were they not warped.

Btw those pics are to demonstrate shape, probably everyone knows, but the amount needex on a platter is more a difference of 1-3mm at most from the center I would imagine.

Being slightly concave makes it so the LP when center weighted will more evenly press against the platter.

I was coming from a different angle: the LP - when center-weighted and with a periphery ring around it - would "hug" a convex platter. But I guess here, without a periphery ring (which, as I realize now, isn't there), pushing the LP down into the "cave" would probably have a similar effect.

Ah, I did not know the relationship between bar and PSI. Thanks for that. I set my three Vibraplanes at 80 PSI.

The compressor pressure is not the working pressure of the pneumatic chambers. You have valves and the pressure of each chamber is determined by the amount of air that is allowed to go in the chamber. As we can expect that the load of each chamber is different in most situations, the idolators will probably have different pressures.

You could use a convex platter that is 1-3mm higher around the label, and a periphery ring, without a center weight. That would be another way to couple an LP more.

David, what is the difference in height between the outermost groove and the innermost groove with your new platter, and is the device over the spindle a clamp or weight? Also, are most customers using the bare metal surface or the leather mat? Thanks.

That’s ours to keep as is the special grade of stainless we’re using. As far as I know everyone is using a mat, it was always part of the design. Over the years I’ve tried many different skin types with various dyes in several thicknesses to know their effect, one can tune the sound further to taste changing them within the original parameters and without the negative impact of wrong mats, it’s just a matter of experience.David, what is the difference in height between the outermost groove and the innermost groove with your new platter, and is the device over the spindle a clamp or weight? Also, are most customers using the bare metal surface or the leather mat? Thanks.

I don’t like clamps user error can become a factor during application and they’re inconvenient, user experience matters!

david

That’s ours to keep as is the special grade of stainless we’re using. As far as I know everyone is using a mat, it was always part of the design. Over the years I’ve tried many different skin types with various dyes in several thicknesses to know their effect, one can tune the sound further to taste changing them within the original parameters and without the negative impact of wrong mats, it’s just a matter of experience.

I don’t like clamps user error can become a factor during application and they’re inconvenient, user experience matters!

david

Thanks, that all makes sense. I am sure you can guess about the reason I ask about the height difference between the outermost and innermost grooves: if it varies by more than 0.5mm, would that not effect SRA if the stylus is basically going down hill toward the center of the LP. If the platter is concave, the stylus will running down hill during play. We both know that a height change of 0.5mm can effect the sonics pretty dramatically. Will the initial set up procedure for SRA remain the same or do you suggest clients fine tune SRA by listening to a groove in the center of the LP as it will represent an "average SRA" for that LP at that location in the grooves?

Folsom mentioned a convex platter raised at the center by 1-3mm. That seems like a lot and in that case, the stylus would be running uphill toward the innermost groove and surely SRA would be constantly changing during the course of the LP. VTF and overhang would also change, but I think those changes would be inaudible, based on my experiments.

Do you not see this uphill or downhill path being problematic? Is there a flaw in my questioning?

I would be more worried about anti-skate and wear to the LP and stylus over time. At the same time, I can see anti-skating actually being helped here

Thanks, that all makes sense. I am sure you can guess about the reason I ask about the height difference between the outermost and innermost grooves: if it varies by more than 0.5mm, would that not effect SRA if the stylus is basically going down hill toward the center of the LP. If the platter is concave, the stylus will running down hill during play. We both know that a height change of 0.5mm can effect the sonics pretty dramatically. Will the initial set up procedure for SRA remain the same or do you suggest clients fine tune SRA by listening to a groove in the center of the LP as it will represent an "average SRA" for that LP at that location in the grooves?

Folsom mentioned a convex platter raised at the center by 1-3mm. That seems like a lot and in that case, the stylus would be running uphill toward the innermost groove and surely SRA would be constantly changing during the course of the LP. VTF and overhang would also change, but I think those changes would be inaudible, based on my experiments.

Do you not see this uphill or downhill path being problematic? Is there a flaw in my questioning?

Of course the slope is minimal Peter as not to impact the normal operation of the tonearm and that’s what makes production very difficult and it’s all hand machined.

david

Of course the slope is minimal Peter as not to impact the normal operation of the tonearm and that’s what makes production very difficult and it’s all hand machined.

david

I would think that something like 0.25mm down from outside to inside would be sufficient for improving record/platter contact, especially with a compliant mat interface like leather, if the center weight was sufficiently heavy to flex/bend heavy weight vinyl. I like the idea. It makes sense, but I bet it is difficult to machine such a thing by hand. I also like the notion that it eliminates the complications of vacuum hold down. Congratulations David!

...

I don’t like clamps user error can become a factor during application and they’re inconvenient, user experience matters!

david

The Monaco 2's screw-on clamp goes a long way to removing user error, or at least making it repeatable. Screw down the clamp, when it reaches a specific pressure an LED lights in the center of the clamp. If you don't like the default, the pressure sensor is adjustable.

It’s still inconvenient, you need to stop the platter unscrew and the screw down until the light comes on and then startup all over again and then stop and unscrew again, again and again.... Then there’s the question of additional sensors and lights that can malfunction, over complication of the simple weight that you can remove or add without having to stop the spinning platter and you have consistency because of the fixed mass.The Monaco 2's screw-on clamp goes a long way to removing user error, or at least making it repeatable. Screw down the clamp, when it reaches a specific pressure an LED lights in the center of the clamp. If you don't like the default, the pressure sensor is adjustable.

david

It’s still inconvenient, you need to stop the platter unscrew and the screw down until the light comes on and then startup all over again and then stop and unscrew again, again and again.... Then there’s the question of additional sensors and lights that can malfunction, over complication of the simple weight that you can remove or add without having to stop the spinning platter and you have consistency because of the fixed mass.

david

to be honest, when I had a mates Monaco for 3 months - the constant screwing and unscrewing the clamp really frustrated me. In the end I stopped using the clamp it was such a pita.

personally I prefer the sound of my tables without clamp/weight - I do spend more time than ever flattening new release vinyl thou

YMMV

It’s still inconvenient, you need to stop the platter unscrew and the screw down until the light comes on and then startup all over again and then stop and unscrew again, again and again.... Then there’s the question of additional sensors and lights that can malfunction, over complication of the simple weight that you can remove or add without having to stop the spinning platter and you have consistency because of the fixed mass.

david

Those two words sum up audio's greatest sin.

It’s still inconvenient, you need to stop the platter unscrew and the screw down until the light comes on and then startup all over again and then stop and unscrew again, again and again.... Then there’s the question of additional sensors and lights that can malfunction, over complication of the simple weight that you can remove or add without having to stop the spinning platter and you have consistency because of the fixed mass.

Does not seem all that complex or inconvenient in my room.

To take this up in th same vein - taking off a weight, sitting it down, taking off a record , resleeving it, mounting another record, installing a weight all while a massive, heavy platter spins, seems very complex - but moreso seems fraught with danger. Perhaps some are perfect every single time. Perhaps dropping an N gram weigh on a moving record has zero potential negative impact on anything. If convenience s paramount, there's always streaming. ;-)

There is some satisfaction in the pace of vinyl ritual. I don't mind it.

Does not seem all that complex or inconvenient in my room.

To take this up in th same vein - taking off a weight, sitting it down, taking off a record , resleeving it, mounting another record, installing a weight all while a massive, heavy platter spins, seems very complex - but moreso seems fraught with danger. Perhaps some are perfect every single time. Perhaps dropping an N gram weigh on a moving record has zero potential negative impact on anything. If convenience s paramount, there's always streaming. ;-)

There is some satisfaction in the pace of vinyl ritual. I don't mind it.

I don't mind the ritual either, including the need to turn of the spinning platter to change LPs and screw on the clamp.

Similar threads

- Replies

- 483

- Views

- 64K

- Replies

- 33

- Views

- 15K

- Replies

- 30

- Views

- 24K

- Replies

- 75

- Views

- 32K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |