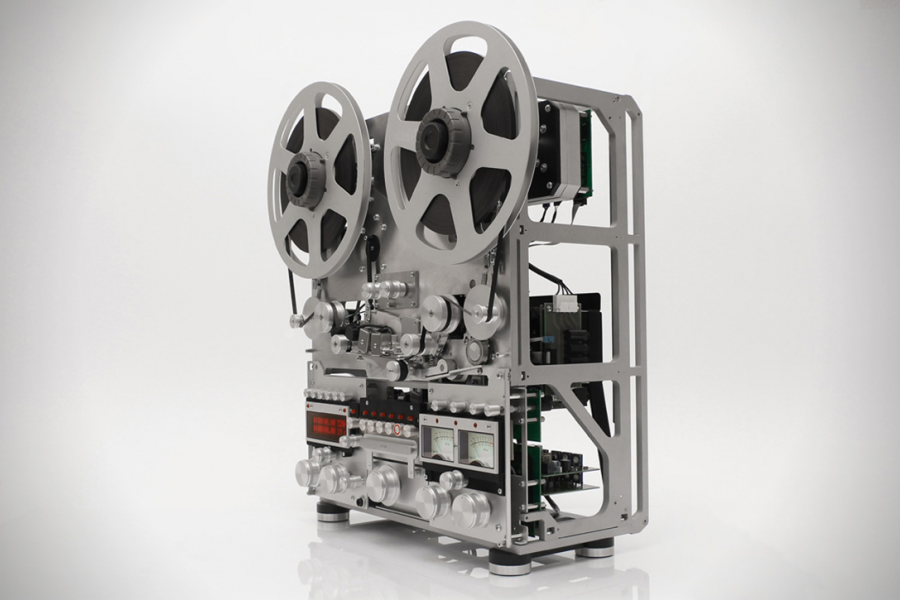

If magnetic head and audio electronics for M063 and Thorens TM1600 were all the same, I predict TM1600 will hold its promise for a longer time. No hard to comprehend theory is involved; only simple common sense. Tape transport is mechanical in nature. For any movable parts to operate smoothly there must be some "play" (uncertainty) to make the movement fluent. This uncertainty will increase as parts move (grind) against each other every time (at each command?); i.e. as mechanical part wear out. Conventional wisdom put magnetic heads in solid foundation; ensure its alignment with lacquer on the micro-pitch screws.

Another simple question followed as: move tape away from magnetic heads or move magnetic heads away from tape? which task is easier? Judging from sheer mass of magnetic head and amount of magnetic tape involved the answer should be quite obvious.

This principle also holds for video tape recorder: very complicated mechanism pull the tape out of the box and wrap it around a fixed rotating heads.

Tape enthusiasts can ask opinion from experts at April 25 Berkeley's Reel Tape Workshop.

Another simple question followed as: move tape away from magnetic heads or move magnetic heads away from tape? which task is easier? Judging from sheer mass of magnetic head and amount of magnetic tape involved the answer should be quite obvious.

This principle also holds for video tape recorder: very complicated mechanism pull the tape out of the box and wrap it around a fixed rotating heads.

Tape enthusiasts can ask opinion from experts at April 25 Berkeley's Reel Tape Workshop.