You have to proceed systematically, otherwise you're just groping in the dark.

Connect the speakers and put a short-circuit plug on the RCA input of the amp.

This will ensure that the humming is not coming from other devices. Does the humming change when you adjust the volume? Download the audio tool app and hold the cell phone microphone directly to the speaker.

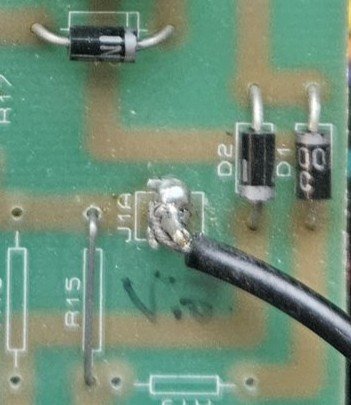

At what frequency is the humming? 50hz or 60hz is usually a grounding problem. Different grounding concepts, bad wiring or soldering points.

Higher frequency humming can be caused by defective rectifiers ,coupling capacitors, srrp whistling (gradual increase in hum). If the volume doesn't change no matter what you set, it's usually a (grounding) problem.

Connect the speakers and put a short-circuit plug on the RCA input of the amp.

This will ensure that the humming is not coming from other devices. Does the humming change when you adjust the volume? Download the audio tool app and hold the cell phone microphone directly to the speaker.

At what frequency is the humming? 50hz or 60hz is usually a grounding problem. Different grounding concepts, bad wiring or soldering points.

Higher frequency humming can be caused by defective rectifiers ,coupling capacitors, srrp whistling (gradual increase in hum). If the volume doesn't change no matter what you set, it's usually a (grounding) problem.